We Are Closing the Cycle:

Your Expert Partner for Thermal and Biological Energy-from-Waste Plants

Our solutions are based on effi cient and environmentally sound in-house technology, and cover the entire life cycle of an Energy-from-Waste facility. Our proven technologies have been part of more than 700 plants worldwide. As a global leader in energy from waste we are proud to be able to say:

We deliver. Check our references.

Waste is our Energy www.hz-inova.com

HZI_Anzeige_Image_Unternehmen_Anlage_155x235_EN_RZ.indd 1 02.06.17 13:58

179 Size Matters: The Construction of the World’s Largest Waste-to-Energy Plant in Dubai

Waste Incineration

Size Matters:

The Construction of the World’s Largest Waste-to-Energy Plant in Dubai

Andres Kronenberg and Manuela Höllinger

1. Greening a megacity: Dubai’s sustainability strategy ...180

2. Birth of a major project ...181

2.1. Success lies in addressing local environmental factors ...182

2.1.1. Site before the gates of a global city ...183

2.1.2. Maximising performance: top energy-efficiency in the desert ...184

2.1.3. Addressing unknown waste composition with optimum combustion ...187

3. Project development: the foundation for success in technical, financial and human terms ...188

3.1. Consortium guarantees entire range of expertise ...188

3.1.1 Collaboration of specialists guarantees integrated concept and design ...189

3.1.2 Precisely catering to the market and needs ...190

3.1.3 The best of all worlds: cross-border teamwork ...190

3.1.4 Boosting public acceptance: getting those affected involved ...191

4. Energy from waste: forward-looking solutions for global cities ...191

With an annual throughput of 1,825,000 metric tonnes and net energy efficiency of more than 31 %, the new Energy from Waste plant (EfW) to be completed in Dubai in the next few years will be the largest and most efficient in the world. The project is unique of its type, and in an environment that poses challenges unlike those encoun- tered anywhere else in the world for everyone concerned, is incredibly demanding in terms of project development, technology and long-term planning.

The contract to construct and operate the plant was awarded to a consortium consisting of Swiss cleantech company Hitachi Zosen Inova (HZI) and Belgian construction firm BESIX. In this article we map out the success factors critical in an undertaking of this scale and how to tackle them to ultimately be able to operate an EfW plant that will lead the world in terms of throughput and energy efficiency.

Andres Kronenberg, Manuela Höllinger

180

Waste Incineration

1. Greening a megacity: Dubai’s sustainability strategy

The goals are ambitious: by 2021 Dubai plans to be the most sustainable smart metro- polis in the world. In concrete terms this means slashing the number of landfill sites by 75 %, reducing carbon emissions by 16 % and covering at least 7 % of its energy requirements with clean resources. The aim is to raise this figure to 25 % by 2030, and to a whole 75 % by 2050. In recent years the government has implemented various green initiatives – programmes designed to conserve natural resources and integrate alternative and renewable energy in Dubai’s energy mix – to make this vision reality.

They include developing and implementing a regulated waste management system.

An important step in the transformation is constructing and operating an energy from was- te (EfW) plant to process around 8,000 metric tonnes of waste the city produces each day.

Figure 1: Dubai skyline: the metropolis produces around 8,000 metric tonnes of waste per day

Source: Pixabay, Werner Satzger

Superlative Performance

In the next few years the world’s biggest EfW installation is to be built in the Al War- san district, around 10 kilometres outside the city centre. Besides its sheer size, it will be the overall efficiency of the plant that makes it so unique. With energy efficiency of more than 31 %, Dubai’s future waste treatment plant will rank at the very top by international standards.

181 Size Matters: The Construction of the World’s Largest Waste-to-Energy Plant in Dubai

Waste Incineration

The contract to develop, build and operate this major plant has been awarded to the mentioned consortium. Within the partnership HZI will supply the technology for all the process components, while BESIX will provide the construction itself. Since the local authorities so far have no experience with building EfW plants of this size, besides supplying the technology and taking care of construction the contract also stipulates that the consortium will finance and operate the plant on behalf of the City of Dubai, and then hand it over, for a period of 30 years.

At full capacity the plant’s five combustion lines will process 5,000 metric tonnes a day, or over 1.8 million tonnes a year, of non-recyclable municipal solid waste and commercial waste to generate up to 190 MW of electrical energy – around 2 % of Dubai’s power requirements, or around 120,000 households. Additional benefits of an installation of this sort include the ability to recycle metals and recover building materials from the bottom ash. By eliminating the need for landfill, it will also significantly reduce emissions of methane gas, with a direct influence on the project’s environmental compatibility.

2. Birth of a major project

The City of Dubai presented the project for the first time in June 2016. The decision to build an EfW plant of this size in the emirate was prompted by the fact that the metropolis has grown rapidly in recent decades and continues to expand. In 2014 the population was producing around 7,000 tonnes of waste per day; only four years later Figure 2: Warsan overview: in the years to come, the largest waste recycling plant in the world

will be built on the Warsan site

Source: Google Earth, edited

Al Hamra

WTE Umm Al Quwain

Sharja DhabiAbu

Dubai

The World Islands

The Palm Jumeirah

Dubai International

Airport RashidPort

University City

Al Qusais Landfill

Khawaneej Al

Dubai

WTE Deira

0 2,000 meters

4,000

Regional setting of the Project site Dubai Resource Recovery

Facility date

23/04/2018

Andres Kronenberg, Manuela Höllinger

182

Waste Incineration

the city reports that this figure has already risen to more than 8,000 tonnes. Apart from reasons of space, the main motivation was the environment and the ambition of realising the goals of the sustainable waste management strategy formulated in 2012.

In the initial tender the contract was presented as a DBO (design, build and operate) project. But following various discussions on developing the project and the complexity of implementing an efficient waste management set-up, the undertaking was ultimately tendered as a DBFO (design, build, finance and operate) project. The final decision to award the contract to the consortium was made in January 2018. At the time of this writing, work on project development and on the technical and construction aspects of the installation is in full swing.

Figure 3: Architectual overview: each year, 1,825,000 metric tonnes of waste are treated in five lines;

the resulting 190 MW of electrical energy covers 2 % of the Dubai electricity requirement

2.1. Success lies in addressing local environmental factors

The site, in an industrial zone in the desert of Dubai, only displays a limited number of the characteristics usually encountered in the locations EfW plants are built. Various factors presented the project team with challenges they had never encountered before.

Besides factors directly impacting the implementation of the technical components, they have also had to safeguard different aspects of the vegetation and the human en- vironment. To demonstrate the sustainability of the plant, an environmental and social impact assessment (ESIA) was conducted by an independent institute in the run-up to the project. It included a detailed analysis of the environment and measurements of air quality and noise emissions.

183 Size Matters: The Construction of the World’s Largest Waste-to-Energy Plant in Dubai

Waste Incineration

2.1.1. Site before the gates of a global city

The Warsan district, owned by the City of Dubai administration, consists of various industrial, commercial and recreational areas, including a municipal coal-fired power station, a demineralised water plant and various warehouses, a polo club and hotel, and, somewhat removed, residential areas. This has both advantages and disadvantages.Figure 4: Warsan zones: the project development takes into account the local conditions of the area on which the future facility will be built

The EfW plant is to be built on the east of the district next to the Al Aweer water treatment plant. The site has various advantages: water is treated in two stages in the waste water works before being fed into the EfW plant as process water. Instead of being fed back into the demineralised water plant, it will be recycled and stay in the EfW plant’s water steam cycle, eliminating the need to use any more of the city’s scarce water supplies.

The location is fairly unproblematic in terms of biodiversity. Situated in the middle of an industrial zone, with waste unloaded on the landfill site, there is little flora and fauna around the site. It’s another story when it comes to the human habitat. While there are no residential areas directly adjacent, there are people close by who will be aware of the plant in some way, both during construction and once the plant is commissioned.

To prevent noise and odour emissions early in in the process, countermeasures were evaluated and implemented in the preparatory phase. For example deliveries of waste

0 200 meters

400 600 800

surrounding landuse Dubai Resource Recovery

Facility date

24/04/2018

Project site Legend

Surrounding Landuse Academic City Commercial Area Industrial Area Place of Worship Residential Area Resource / Attraction WTE

Dubai International City

(Phase 2)

Dubai International Academic City

(DIAC) Dubai

International City (Phase 1)

Al Aweer Sewage

Treatment Plant Dubai

Plant Nursery Tadweer Waste Treatment

Warsan Garbage Dump

Emirates Engine Maintenance

Center DEWA Power

Station

DEWA Site Office

Industrial Facilities Dubai Textile

City Dragon Mart Commercial Center

Desert Palm Polo Club and Hotel Pivot Fields

Warsan Lake

Al Warqa 4

Dubai Safari

Andres Kronenberg, Manuela Höllinger

184

Waste Incineration

by lorry mean an anticipated increase in traffic. To prevent congestion on the main road, an extra feeder road is being built for vehicles to access the plant. Waiting areas will ease the problem additionally when there is a lot of traffic in the tipping zone.

2.1.2. Maximising performance: top energy-efficiency in the desert

The two Ferrybridge EfW plants in the UK lead the world with net energy efficiency of over 31 %. The Riverside plant in London is also close to the top of the rankings with more than 27 %. Although it will be one of the front-runners with net energy efficiency of 31 %, on paper there is nothing particularly striking about the upcoming Dubai plant.

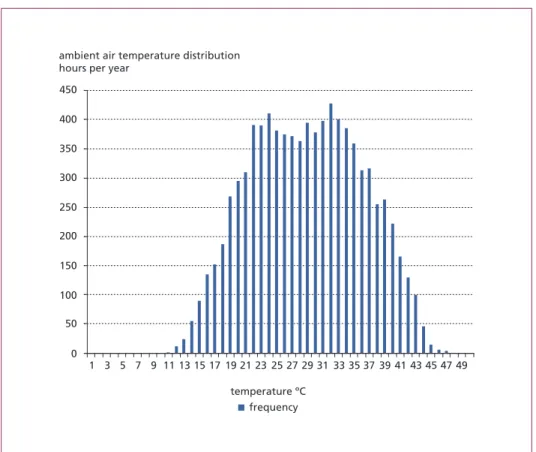

But factor in the completely different set of external factors confronting the installation in the desert and a very different picture emerges, catapulting the Dubai EfW plant well into the lead. The reason for this discrepancy is both relatively simple and highly complex: with an annual average temperature of around 27 °C, the conditions for high efficiency are much less favourable, say, than the 15 °C average temperature in the UK.

If the same plant were in Manchester rather than Dubai, you could expect to see net energy efficiency as high as 32 %.

ambient air temperature distribution hours per year

450 400 350 300 250 200 150 100 50 0

1 3 5 7 9 11 13 15 17 19 21 23 25 27 29 31 33 35 37 39 41 43 45 47 49 temperature ºC

frequency

Figure 5: Outside temperatures influence the overall system efficiency. If the investment were in London instead of Dubai, the value would have been appreciably higher

When it comes to efficient waste gas treatment, HOK® Activated Lignite is the ideal fresh sorbent.

Thanks to our own raw materials base, we are one of the world’s

largest producers of activated lignite. This guarantees security of supply.

The constant high quality of HOK® ensures a reliable separation of harmful substances.

HOK® Activated Lignite. Good for the environment, good for business.

www.hok.de

ACTIVATED LIGNITE AT ITS BEST

RBB-HOK_Anzeige_155x235_EN_Waste_to_energy_RZ.indd 1 01.07.19 14:37

When it comes to efficient waste gas treatment, HOK® Activated Lignite is the ideal fresh sorbent.

Thanks to our own raw materials base, we are one of the world’s

largest producers of activated lignite. This guarantees security of supply.

The constant high quality of HOK® ensures a reliable separation of harmful substances.

HOK® Activated Lignite. Good for the environment, good for business.

www.hok.de

ACTIVATED LIGNITE AT ITS BEST

RBB-HOK_Anzeige_155x235_EN_Waste_to_energy_RZ.indd 1 01.07.19 14:37

RAW GAS MEASUREMENT:

LOWERING COSTS WITH DATA TRANSPARENCY.

What use is the technologically advanced gas purification if gas concentrations in raw gas cannot be detected quickly ‒ hydrochloric acid, sulfur dioxide and even mercury? With accurate measured values within 30 seconds, the rugged and corrosion-resistant MCS300P HW and MERCEM300Z gas analysis systems from SICK really impress. Gas concentration changes are displayed in a timely manner and simplify the control to keep concentrations below requested emission limit values. Even peaks are safely detected. The quick measurement results also help reduce costs: From now on, only the chemical consumption actually needed for the process has to be considered. We think that’s intelligent. www.sick.com/waste

Ad_RawGasMeasurement_155x235+3mm_EN_20190418.indd 1 18.04.2019 11:26:11

187 Size Matters: The Construction of the World’s Largest Waste-to-Energy Plant in Dubai

Waste Incineration

Th e limiting factor here is the air-cooled condenser (ACC) that condenses the steam.

Desert environments with high temperatures and extreme weather phenomena such as sandstorms pose multiple risks for the ACC. Th e alternative, building a cooling tower, was not an option in Dubai, because there is no appropriate source of water nearby and pumping it from such a distance would not be effi cient.

So the design of the plant had to take account for the fact that external temperatures do not permit additional air cooling of the steam. Th is meant the ACC had to be bigger.

Th is in turn results in higher energy consumption coupled with lower electricity out- put. Another issue is desert sand clogging up the surface of the ACC and preventing air from fl owing through. To prevent this from happening, the ACC has to be cleaned much more oft en and thoroughly than for other plants, which also has a negative impact on the energy balance.

2.1.3. Addressing unknown waste composition with optimum combustion

Besides these obstacles, the waste composition and size of the installation are a challenge in terms of optimising the overall effi ciency of the plant. Until now the emirate’s entire waste has been disposed of in landfi ll outside the city. Th e problem with this is that the actual composition of the waste is to a large extent unknown. Reliably operating a plant of this size that has to deal with such extremely heterogenous waste compositions requires outstanding combustion and control technology. Th is is where a proprietary development comes in: in addition to the regular combustion control system, at the Du- bai plant the expanded combustion control system (CCS+) also helps assure optimum burnout of the waste. Th e system facilitates combustion by automatically matching it to the composition of the waste being incinerated; this also happens over the long term as the waste composition changes, for example as a result of higher recycling rates or the introduction of separate waste collection.Th e control system monitors combustion in the plant and provides up-to-the-second data which activates troubleshooting processes when required or in the event of dis- ruption. Th e fl exible system serves as the interface between safety-critical logics in the control system and complex, partially automated control algorithms that are not part of it. Th is way the system enhances combustion stability, even when the composition of the waste fl uctuates, enabling optimum combustion results and compliance with emission limits. With the best possible combustion process, this plant can be expected to achieve waste throughput of 46 t/h per line. Th is requires a grate with extraordinary dimensions. Measuring 12 by 15 metres, the grate built into the Dubai plant is the biggest model ever made by the technology supplier.

Th anks to refi ned control algorithms and additional sensors, CCS+ is much more highly automated than existing combustion control systems and provides more detailed data than was previously possible Th is means plant-specifi c safety margins can be exploited more eff ectively to optimise operation. At the same time there is still the option of intervening manually in the combustion process. Th e system thus relieves the burden on staff but does not replace them.

Andres Kronenberg, Manuela Höllinger

188

Waste Incineration

Better burnout ensures that the flue gas treatment already meets the highest quality requirements during the combustion phase, meaning the plant not only complies with the statutory limits, but comes in well below them. Optimum gas burnout also reduces oxygen content, which in turn lowers the volume of flue gas and thus the consumption of energy. It also cuts consumption of SNCR reagent and reduces fly ash.

3. Project development: the foundation for success in technical, financial and human terms

Given that there is so little experience in the region in operating waste treatment plants and that so many unknown or barely known external factors are at play, the installati- on of CCS+ and the overall design of the EfW plant in Dubai are crucial. The project takes account of these circumstances with carefully thought-out plant and operating concepts designed to allow a flexible response to short-term changes, for example in legislation or emission limits.

3.1. Consortium guarantees entire range of expertise

In its tender the end-client, the City of Dubai, specified that the supplier would also be responsible for overall project development. The consortium was thus confronted with various circumstances that none of the consortium partners had had to deal with in Figure 6: CCS+: waste composition and combustion technology have a significant impact on overall

plant performance

thermal power of waste MW

waste throughput tons per hour 140

130 122 MW

85 MW

27.8 t/h 46.3 t/h 52.5 t/h

14,000 kJ/kg 9,500 kJ/kg

7,000 kJ/kg 120

110 100 90 80 70

20 25 30 35 40 45 50 55 60 65

189 Size Matters: The Construction of the World’s Largest Waste-to-Energy Plant in Dubai

Waste Incineration

previous projects. The city was in negotiation with both the potential building contrac- tor and the technology provider. In the course of the initial discussions synergy effects emerged, and the two companies decided to join forces. Alongside technical expertise and flexibility, a well-trained regional network was a prerequisite for the contract.

BESIX has a local subsidiary (SIXCO) and has had a strong presence in the region for many years. In addition to being involved in the construction of Burj Khalifa, the Belgian company headed construction of Ferrari World in Abu Dhabi as well. It can also draw on experience gathered in the construction of various water treatment and desalination plants in the Arab region. Collaborating on this prestigious large project thus opened the door to a new market segment for both companies.

3.1.1. Collaboration of specialists guarantees integrated concept and design

The end-client’s point of contact is the special-purpose vehicle (SPV) set up for the project, which consists of HZI, BESIX and the Japanese company Itochu. The SPV also has external teams of finance specialists and legal and environmental advisors intimately acquainted with local circumstances. To cover finance, technology, legal and client relationship management, the SPV itself has its own teams of specialists who follow a multi-phase time schedule defined in advance by the SPV steering committee in close consultation with the downstream teams. It goes without saying that, in all this, quality and deadlines are monitored extremely closely to keep track of all processes and ongo- ing activities. This allows early corrective intervention if things deviate from the plan.Figure 7: BOOT: the consortium is deployed on various own and external expert teams

Steering Committee

SPV Coordination

SPV Financial

Financial Team

SPV Legal

Legal Team

SPV Technical

Technical Team

Project Director EPC O&M Team SPV Customer Relation

Commercial Team

Financial Advisor

Model Auditor Tax Advisor

Insurance

Advisor Technical

Advisor Legal

Councel EIA

Consultant ECA

Coordinator

ITOCHU Corporation BESIX

Group Hitachi Zosen Inova AG

Andres Kronenberg, Manuela Höllinger

190

Waste Incineration

3.1.2. Precisely catering to the market and needs

An essential aspect of the initial project development phase was the issue of waste: the composition of the waste as the basis for defining the technical specifications of the plant, and the important role played by the organisation of the city’s waste management system.

Until now, waste has been collected on behalf of the city by sub-contractors and tipped at one of the landfill sites. This collection set-up will remain in place in the future, with the difference that waste will be transported to the plant, with the transport companies remunerated by the city for doing so. This separation of transport and the tipping fee, standard practice for landfill disposal, ensures that the sub-contractors perform their duties and bring the waste to the plant. The big challenge is setting tipping fees that the city will accept and cover. This means a steady, albeit very moderate increase compared to the costs of landfill disposal. At the same time the plant, in addition to payment for the electricity it produces, should generate fees that enable it to be amortised within an economically reasonable timeframe. The trick here was to develop different financing models taking account of price sensitivity and creating the necessary scenarios for the purposes of further planning.

3.1.3. The best of all worlds: cross-border teamwork

Very early on in the development process the various working groups had to think about the delivery of the project to foresee and pre-empt all eventualities by building the corresponding measures into the concept and design of the plant. This applied, for example, to the personnel policy for the project team. One requirement was that local resources be used on both the staff and supplier side. The project will thus be managed by a local onshore team with the support of an offshore team in Zurich. The onshore team in Dubai will consist of local specialists and selected expats. This strat- egy will guarantee that local customs and practices are taken into account and boost acceptance in the region.

At peak times there will be more than 1,000 people working on the site. This also has to be factored in at an early stage and planning geared accordingly. This includes, for example, providing accommodation and prayer zones for construction staff and, one of the most important considerations, making sure all the safety requirements are met.

If workers have accommodation on site, explicit requirements have to be met in terms of safety, noise protection and quiet time. If workers have accommodation off site, they have to be guaranteed safe transportation.

The same principle applies to the 30-year period of operation agreed by consortium partners with the City of Dubai. In its capacity as the operating company, the SPV not only bears responsibility for the operation of the plant and achieving the guaranteed output and energy generation; it also has to comply with all the relevant rules and requirements, and service and maintain the plant for long-term operation. To best meet these requirements a concept was developed where operational and maintenance personnel will be based on site. This means building a complete infrastructure on site, including accommodation and the necessary commercial, leisure and prayer facilities.

191 Size Matters: The Construction of the World’s Largest Waste-to-Energy Plant in Dubai

Waste Incineration

3.1.4. Boosting public acceptance: getting those affected involved

The EfW in Dubai is something new for the city. For this reason there has been a need to inform the public right from the moment the project was initiated. From the outset the consortium and the city authorities have taken pains to involve the public by way of face-to-face events and multimedia information material.A visitors’ centre is another move designed to get the public and interested individuals or groups on board. The centre is a place where visitors can find detailed information on the topic and visit part of the installation. The goal is to stress the relevance of the plant and help people overcome their doubts and inhibitions.

4. Energy from Waste: forward-looking solutions for global cities

These days the majority of European countries use EfW technology to thermally treat their municipal solid waste. Almost all cities and large towns in central and northern Europe have EfW plants ranging from relatively large to relatively small that process waste and at the same time serve as an important source of energy.

The principle of growth also governs waste management. For example, more than ten new plants are currently being built in the UK, with a handful more to be extended in the next few years. EfW technology is also gaining traction in Russia, with five plants with a waste throughput of 700,000 or 570,000 t/a currently under construction in the Figure 8: The EfW plant is not just a place of waste recycling; living space for employees is also

being created on the site

Bottom Ash Treatment Air cooled Condenser

Flue Gas Treatment Stacks

Sludge-Storage and Handling

Waste Bunker

Tipping Staff Facilities Technical Block

Guard House / Weighbridges / Gates

Access to Plant Boiler Hall

Turbine Hall

Substration

Administration and Visitors

Access Staff and Visitors Checkpoint Accommodation

Andres Kronenberg, Manuela Höllinger

192

Waste Incineration

Moscow area, and one in Kazan. The biggest plant in Europe is currently being built in Istanbul. With an annual throughput of 1 million tonnes, this installation will treat waste from the Turkish megacity to generate 70 MW of electricity.

Figure 9:

Construction site: Europe‘s lar- gest EfW plant is being built in Istanbul

Figure 10:

Mexico City will rely on EfW technology in the future To the west, Mexico is also in the starting blocks in terms of thermal waste treatment, with the project in Mexico City likewise at a very early stage of development. The same applies to Singapore, due to build its second EfW plant in the next few years.

These are just some examples illustrating the relevance of EfW installations for global megacities and their agglomerations. Thanks to the dual use of waste treatment and energy recovery, combustion technology is likely to gain major important in the future, also, or particularly, in megacities that have to rapidly find effective means to treat their waste. Through all these projects, from Istanbul and Mexico City to the plant in Dubai described above, HZI is a reliable constant in the successful delivery of these kinds of major undertakings.

193 Size Matters: The Construction of the World’s Largest Waste-to-Energy Plant in Dubai

Waste Incineration

Contact Persons

Andres Kronenberg Chief Business Development Hitachi Zosen Inova

Hardturmstrasse 127 8005 Zurich

SWITZERLAND +41 442771111

andres.kronenberg@hz-inova.com Manuela Höllinger

Hitachi Zosen Inova Head of Communication Hardturmstrasse 127 8005 Zurich

SWITZERLAND +41 442771457

manuela.hoellinger@hz-inova.com

Dorfstraße 51

D-16816 Nietwerder-Neuruppin

Phone: +49.3391-45.45-0 • Fax +49.3391-45.45-10 E-Mail: order@vivis.de

TK Verlag GmbH

order now www. .de

Energy from Waste

Energie aus Abfall, Volume 1 (2006) ISBN: 978-3-935317-24-5 20.00 EUR Energie aus Abfall, Volume 2 (2007) ISBN: 978-3-935317-26-9 20.00 EUR Energie aus Abfall, Volume 3 (2007) ISBN: 978-3-935317-30-6 20.00 EUR Energie aus Abfall, Volume 4 (2008) ISBN: 978-3-935317-32-0 20.00 EUR Energie aus Abfall, Volume 5 (2008) ISBN: 978-3-935317-34-4 20.00 EUR Energie aus Abfall, Volume 6 (2009) ISBN: 978-3-935317-39-9 30.00 EUR Energie aus Abfall, Volume 7 (2010) ISBN: 978-3-935317-46-7 30.00 EUR Energie aus Abfall, Volume 8 (2011) ISBN: 978-3-935317-60-3 30.00 EUR

Energie aus Abfall, Volume 11 (2014) ISBN: 978-3-944310-06-0 50.00 EUR Energie aus Abfall, Volume 10 (2013) ISBN: 978-3-935317-92-4 50.00 EUR Energie aus Abfall, Volume 9 (2012) ISBN: 978-3-935317-78-8 30.00 EUR

Energie aus Abfall, Volume 12 (2015) ISBN: 978-3-944310-18-3 50.00 EUR Energie aus Abfall, Volume 13 (2016) ISBN: 978-3-944310-24-4 75.00 EUR Energie aus Abfall, Volume 14 (2017) ISBN: 978-3-944310-32-9 75.00 EUR Energie aus Abfall, Volume 15 (2018) ISBN: 978-3-944310-39-8 100.00 EUR

490.00 EUR

save 230.00 EUR Energie aus Abfall, Volume 1 – 16

Package Price

Energie aus Abfall, Volume 16 (2019) ISBN: 978-3-944310-45-9 100.00 EUR

Thomé-Kozmiensky und Beckmann

Energie aus Abfall 14 Thomé-Kozmiensky und Beckmann

Energie aus Abfall 14

Thomé-Kozmiensky und Beckmann Energie aus Abfall 11Thomé-Kozmiensky und Beckmann Energie aus Abfall 11 Thomé-Kozmiensky und Beckmann Energie aus Abfall 10 Thomé-Kozmiensky und Beckmann Energie aus Abfall 10 Thomé-Kozmiensky und Beckmann Energie aus Abfall 9 Thomé-Kozmiensky und Beckmann Energie aus Abfall 9

Thomé-Kozmiensky und Beckmann Energie aus Abfall 8

Thomé-Kozmiensky und Beckmann Energie aus Abfall 8

Thomé-Kozmiensky und Beckmann Energie aus Abfall 7 Thomé-Kozmiensky und Beckmann Energie aus Abfall 7

Thomé-Kozmiensky und Beckmann Energie aus Abfall 6 Thomé-Kozmiensky und Beckmann Energie aus Abfall 6

Thomé-Kozmiensky und Beckmann Energie aus Abfall 5 Thomé-Kozmiensky und Beckmann Energie aus Abfall 5

Thomé-Kozmiensky und Beckmann Energie aus Abfall 4 Thomé-Kozmiensky und Beckmann Energie aus Abfall 4

Thomé-Kozmiensky und Beckmann Energie aus Abfall 3 Thomé-Kozmiensky und Beckmann Energie aus Abfall 3

Thomé-Kozmiensky Beckmann Energie aus Abfall 2 Thomé-Kozmiensky Beckmann

Thomé-Kozmiensky Beckmann Thomé-Kozmiensky Beckmann Thomé-Kozmiensky Beckmann Thomé-Kozmiensky Beckmann Thomé-Kozmiensky Beckmann Thomé-Kozmiensky Beckmann Thomé-Kozmiensky Beckmann Thomé-Kozmiensky Beckmann Thomé-Kozmiensky Beckmann Thomé-Kozmiensky Beckmann Thomé-Kozmiensky Beckmann Thomé-Kozmiensky Beckmann Thomé-Kozmiensky Beckmann Thomé-Kozmiensky Beckmann Thomé-Kozmiensky Beckmann Thomé-Kozmiensky Beckmann Thomé-Kozmiensky Beckmann Thomé-Kozmiensky Beckmann Thomé-Kozmiensky Beckmann Thomé-Kozmiensky Beckmann

Thomé-Kozmiensky Beckmann Energie aus Abfall 2 Energie aus Abfall 2 Energie aus Abfall 2 Energie aus Abfall 2 Energie aus Abfall 2 Energie aus Abfall 2 Energie aus Abfall 2 Energie aus Abfall 2 Energie aus Abfall 2 Energie aus Abfall 2 Energie aus Abfall 2 Energie aus Abfall 2 Energie aus Abfall 2 Energie aus Abfall 2 Energie aus Abfall 2 Energie aus Abfall 2 Energie aus Abfall 2 Thomé-Kozmiensk

yBeckmann

Energie aus Abfall 1

Thomé-Kozmiensk Thomé-Kozmiensk Thomé-Kozmiensk Thomé-Kozmiensk Thomé-Kozmiensk Thomé-Kozmiensk Thomé-Kozmiensk Thomé-Kozmiensk Thomé-Kozmiensk Thomé-Kozmiensk Thomé-Kozmiensk Thomé-Kozmiensk Thomé-Kozmiensk

yBeckmann Beckmann Beckmann Beckmann Beckmann Beckmann Beckmann

Energie aus Abfall 1 Energie aus Abfall 1 Energie aus Abfall 1 Energie aus Abfall 1 Energie aus Abfall 1 Energie aus Abfall 1 Energie aus Abfall 1 Energie aus Abfall 1 Energie aus Abfall 1 Energie aus Abfall 1 Energie aus Abfall 1 Energie aus Abfall 1 Energie aus Abfall 1 Energie aus Abfall 1

Thiel, Thomé-Kozmiensky, Quicker, Gosten Energie aus Abfall 15Thiel, Thomé-Kozmiensky, Quicker, Gosten Energie aus Abfall 15 Thiel, Thomé-Kozmiensky, Quicker, Gosten Energie aus Abfall 16Thiel, Thomé-Kozmiensky, Quicker, Gosten Energie aus Abfall 16Thiel, Thomé-Kozmiensky, Quicker, Gosten Energie aus Abfall 16 Thomé-Kozmiensky und Beckmann Energie aus Abfall 12

Thomé-Kozmiensky und Beckmann Energie aus Abfall 12

hardcover with colored illustrations Energie_aus_Abfall_Engl.pdf 2 28.08.19 15:50

Vorwort

4

Bibliografische Information der Deutschen Nationalbibliothek Die Deutsche Nationalbibliothek verzeichnet diese Publikation in der Deutschen Nationalbibliografie; detaillierte bibliografische Daten sind im Internet über http://dnb.dnb.de abrufbar

Thiel, S.; Thomé-Kozmiensky, E.; Winter, F.; Juchelková, D. (Eds.):

Waste Management, Volume 9 – Waste-to-Energy –

ISBN 978-3-944310-48-0 Thomé-Kozmiensky Verlag GmbH

Copyright: Elisabeth Thomé-Kozmiensky, M.Sc., Dr.-Ing. Stephanie Thiel All rights reserved

Publisher: Thomé-Kozmiensky Verlag GmbH • Neuruppin 2019 Editorial office: Dr.-Ing. Stephanie Thiel, Elisabeth Thomé-Kozmiensky, M.Sc.

Layout: Claudia Naumann-Deppe, Janin Burbott-Seidel, Sarah Pietsch, Ginette Teske, Roland Richter, Cordula Müller, Gabi Spiegel Printing: Universal Medien GmbH, Munich

This work is protected by copyright. The rights founded by this, particularly those of translation, reprinting, lecturing, extraction of illustrations and tables, broadcasting, micro- filming or reproduction by other means and storing in a retrieval system, remain reserved, even for exploitation only of excerpts. Reproduction of this work or of part of this work, also in individual cases, is only permissible within the limits of the legal provisions of the copyright law of the Federal Republic of Germany from 9 September 1965 in the currently valid revision. There is a fundamental duty to pay for this. Infringements are subject to the penal provisions of the copyright law.

The repeating of commonly used names, trade names, goods descriptions etc. in this work does not permit, even without specific mention, the assumption that such names are to be considered free under the terms of the law concerning goods descriptions and trade mark protection and can thus be used by anyone.

Should reference be made in this work, directly or indirectly, to laws, regulations or guide- lines, e.g. DIN, VDI, VDE, VGB, or these are quoted from, then the publisher cannot ac- cept any guarantee for correctness, completeness or currency. It is recommended to refer to the complete regulations or guidelines in their currently valid versions if required for ones own work.