Dorfstraße 51

D-16816 Nietwerder-Neuruppin

Tel. +49.3391-45.45-0 • Fax +49.3391-45.45-10

E-Mail: tkverlag@vivis.de TK Verlag Karl Thomé-Kozmiensky

Order now: www. .de

Thomé-Kozmiensky und Beckmann

Energie aus Abfall 14 Thomé-Kozmiensky und Beckmann

Energie aus Abfall 14

Energy from Waste

Editors: Karl J. Thomé-Kozmiensky and Michael Beckmann • Publisher: TK Verlag Karl Thomé-Kozmiensky

Thomé-Kozmiensky und Beckmann Energie aus Abfall 11Thomé-Kozmiensky und Beckmann Energie aus Abfall 11 Thomé-Kozmiensky und Beckmann Energie aus Abfall 10 Thomé-Kozmiensky und Beckmann Energie aus Abfall 10 Thomé-Kozmiensky und Beckmann Energie aus Abfall 9 Thomé-Kozmiensky und Beckmann Energie aus Abfall 9

Thomé-Kozmiensky und Beckmann Energie aus Abfall 8

Thomé-Kozmiensky und Beckmann Energie aus Abfall 8

Thomé-Kozmiensky und Beckmann Energie aus Abfall 7 Thomé-Kozmiensky und Beckmann Energie aus Abfall 7

Thomé-Kozmiensky und Beckmann Energie aus Abfall 6 Thomé-Kozmiensky und Beckmann Energie aus Abfall 6

Thomé-Kozmiensky und Beckmann Energie aus Abfall 5 Thomé-Kozmiensky und Beckmann Energie aus Abfall 5

Thomé-Kozmiensky und Beckmann Energie aus Abfall 4 Thomé-Kozmiensky und Beckmann Energie aus Abfall 4

Thomé-Kozmiensky und Beckmann Energie aus Abfall 3 Thomé-Kozmiensky und Beckmann Energie aus Abfall 3

Thomé-Kozmiensky Beckmann Energie aus Abfall 2 Thomé-Kozmiensky Beckmann

Thomé-Kozmiensky Beckmann Thomé-Kozmiensky Beckmann Thomé-Kozmiensky Beckmann Thomé-Kozmiensky Beckmann Thomé-Kozmiensky Beckmann Thomé-Kozmiensky Beckmann Thomé-Kozmiensky Beckmann Thomé-Kozmiensky Beckmann Thomé-Kozmiensky Beckmann Thomé-Kozmiensky Beckmann Thomé-Kozmiensky Beckmann Thomé-Kozmiensky Beckmann Thomé-Kozmiensky Beckmann Thomé-Kozmiensky Beckmann Thomé-Kozmiensky Beckmann Thomé-Kozmiensky Beckmann Thomé-Kozmiensky Beckmann Thomé-Kozmiensky Beckmann Thomé-Kozmiensky Beckmann Thomé-Kozmiensky Beckmann

Thomé-Kozmiensky Beckmann Energie aus Abfall 2 Energie aus Abfall 2 Energie aus Abfall 2 Energie aus Abfall 2 Energie aus Abfall 2 Energie aus Abfall 2 Energie aus Abfall 2 Energie aus Abfall 2 Energie aus Abfall 2 Energie aus Abfall 2 Energie aus Abfall 2 Energie aus Abfall 2 Energie aus Abfall 2 Energie aus Abfall 2 Energie aus Abfall 2 Energie aus Abfall 2 Energie aus Abfall 2 Thomé-Kozmiensk

y

Beckmann Energie aus Abfall 1

Thomé-Kozmiensk Thomé-Kozmiensk Thomé-Kozmiensk Thomé-Kozmiensk Thomé-Kozmiensk Thomé-Kozmiensk Thomé-Kozmiensk Thomé-Kozmiensk Thomé-Kozmiensk Thomé-Kozmiensk Thomé-Kozmiensk Thomé-Kozmiensk Thomé-Kozmiensk

y

Beckmann Beckmann Beckmann Beckmann Beckmann Beckmann Beckmann Energie aus Abfall 1 Energie aus Abfall 1 Energie aus Abfall 1 Energie aus Abfall 1 Energie aus Abfall 1 Energie aus Abfall 1 Energie aus Abfall 1 Energie aus Abfall 1 Energie aus Abfall 1 Energie aus Abfall 1 Energie aus Abfall 1 Energie aus Abfall 1 Energie aus Abfall 1 Energie aus Abfall 1 Thomé-Kozmiensky und Beckmann Energie aus Abfall 12

Thomé-Kozmiensky und Beckmann Energie aus Abfall 12

Energie aus Abfall, Volume 1 (2006) ISBN: 978-3-935317-24-5 30.00 EUR Energie aus Abfall, Volume 2 (2007) ISBN: 978-3-935317-26-9 30.00 EUR Energie aus Abfall, Volume 3 (2007) ISBN: 978-3-935317-30-6 30.00 EUR Energie aus Abfall, Volume 4 (2008) ISBN: 978-3-935317-32-0 30.00 EUR Energie aus Abfall, Volume 5 (2008) ISBN: 978-3-935317-34-4 30.00 EUR Energie aus Abfall, Volume 6 (2009) ISBN: 978-3-935317-39-9 30.00 EUR Energie aus Abfall, Volume 7 (2010) ISBN: 978-3-935317-46-7 30.00 EUR Energie aus Abfall, Volume 8 (2011) ISBN: 978-3-935317-60-3 30.00 EUR

Energie aus Abfall, Volume 11 (2014) ISBN: 978-3-944310-06-0 50.00 EUR Energie aus Abfall, Volume 10 (2013) ISBN: 978-3-935317-92-4 50.00 EUR Energie aus Abfall, Volume 9 (2012) ISBN: 978-3-935317-78-8 30.00 EUR

Energie aus Abfall, Volume 12 (2015) ISBN: 978-3-944310-18-3 50.00 EUR Energie aus Abfall, Volume 13 (2016) ISBN: 978-3-944310-24-4 100.00 EUR Energie aus Abfall, Volume 14 (2017) ISBN: 978-3-944310-32-9 100.00 EUR

430.00 EUR

save 190.00 EUR Energie aus Abfall, Volume 1 – 14

Package Price

Pyrolysis/Gasification

Achieving a Closed Carbon & Circular Economy for the Waste Management Sector

– Net Zero Emissions, Resource Efficiency and Conservation by Coupling the Energy, Chemical and Recycling Sectors –

Roh Pin Lee, Alexander Laugwitz, Florian Keller, Christian Wolfersdorf, Friedemann Mehlhose and Bernd Meyer

1. Introduction ...344

2. The future of coal utilization in Germany ...344

3. The waste management hierarchy ...345

4. Gasification as interface technology for closing the carbon cycle ...346

5. From linear to circular carbon economy ...346

6. Comparison of CO2 emissions ...348

7. Case analysis – emissions free olefin production with domestic carbon feedstock ...349

8. Limitations & directions for future research ...352

9. Conclusion ...353

10. Literature ...353 Lignite (namely brown coal) and carbonaceous waste are valuable primary and secon- dary carbon carriers which are generally combusted in Germany mainly for electricity generation. Such linear cradle to grave model is associated with significant CO2 emissions and also represents a waste of precious domestic carbon resources. A coupling of the energy, chemical and waste management sectors, where lignite and waste are used as alternative feedstock to imported crude oil for chemical production, could facilitate a transformation from a linear to a circular carbon economy. In addition to promoting resource efficiency and conservation, such chemical utilization of lignite and waste via the interface technology gasification and the integration of renewably generated green hydrogen could also support closing the carbon cycle. In this article, we evaluate the role of chemical recycling in the waste hierarchy as well as the opportunities and chal- lenges associated with achieving a closed carbon and circular economy for the waste management sector. To illustrate our concept, results from process models evaluations for olefin production in Germany are presented.

Pyrolysis/Gasification

1. Introduction

Global warming, natural resource depletion and economic growth as well as the growing waste problem and associated environmental and human impacts are key challenges which the global community is facing in the 21st century. The transformation of energy systems from fossil fuels to renewable energies, the reduction in primary resource con- sumption and increase in utilization of secondary resources as well as the development from a linear to a circular economy are therefore central objectives for politics, industry and society in numerous countries. In Germany, an important focus – especially in view of its Energy Transition (Energiewende) and the continuous increase in the recycling quota for the waste sector – is thus the sustainable utilization of domestic primary and secondary carbon resources which is compatible with the goals of the Energiewende and the transition towards a circular economy.

Lignite and carbonaceous waste are valuable primary and secondary domestic car- bon resources which are generally combusted in Germany mainly for electricity generation. Such linear cradle to grave model is not only associated with significant greenhouse gas (GHG) emissions as well as other trace components and fine dust, it also represents a waste of precious domestic carbon resources. The development of new and innovative value chains through the chemical utilization (that is chemische Verwertung or rohstoffliche Nutzung) of domestic carbon resources as alternative raw materials for the chemical industry – in contrast to their energetic utilization (that is energetische Verwertung or energetische Nutzung) for electricity and heat production – therefore offers a viable perspective for domestic carbon resources in contributing to closing the carbon cycle.

2. The future of coal utilization in Germany

Germany possesses significant amount of domestic lignite. Its geological resources are estimated at 72.7 billion t, out of which 36.2 billion t are deemed as economically minable [4]. Currently, coal is predominantly combusted in Germany for electricity generation.

This represents a linear concept whereby the carbon inherent in this precious primary carbon resource is fully released as CO2 into the atmosphere.

The focus of Germany’s Energiewende on transiting the country’s electricity produc- tion to renewables has led to the stepwise reduction of fossil generation capacity in the country. This has resulted in significant impacts for German lignite regions namely North Rhine-Westphalia, Saxony, Brandenburg and Saxony-Anhalt where coal mining, power generation and associated industries are major employers. While the release of domestic lignite from power generation poses significant structural challenges for these regions, it also offers a chance for an alternative utilization of coal (e.g. as feedstock for chemical production) whereby carbon is bonded into chemical products instead of being emitted into the atmosphere. Such chemical utilization of coal would not only offer a viable and sustainable perspective for coal regions in Germany, it could also contribute to the achievement of a circular carbon economy.

Pyrolysis/Gasification

3. The waste management hierarchy

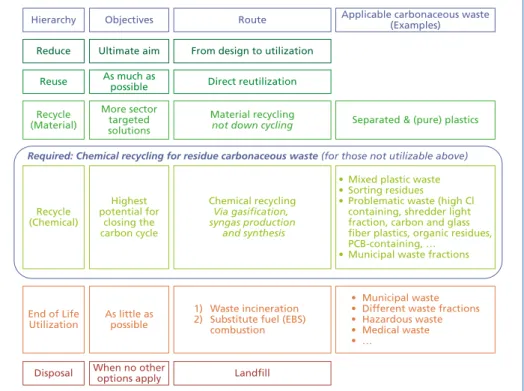

Currently, besides landfill and dumping, waste management globally still refer pre- dominantly to waste incineration. The latter also represents a linear model whereby carbon in the waste are fully released as CO2 into the atmosphere at the end of their lifespan. There is therefore a high potential for a transition in the waste management sector towards other forms of recycling whereby carbonaceous waste resources are channeled back into the economy as products.

In Germany’s circular economy law namely Kreislaufwirtschaftsgesetz - KrWG [2], the waste hierarchy is defined in terms of (1) reduce, (2) preparation for reuse, (3) recycling, (4) other utilization, in particularly energetic utilization and backfilling, and (5) dis- posal. In the case of recycling, while material recycling (werkstoffliche Verwertung bzw.

Nutzung) is focused upon and carried out in certain industrialized societies, chemical recycling (that is chemische Verwertung or rohstoffliche Nutzung) continues to play an insignificant role on the global stage. For residue carbonaceous waste which are not suitable for material recycling, chemical recycling thus poses a feasible alternative to incineration and has the highest potential for closing the carbon cycle.

To increase the overall value we can obtain from our carbon waste resources, we propose the following extended hierarchy for the sustainable management of carbonaceous waste. Specifically, chemical recycling is recognized as a separate and equally important sector in the waste hierarchy (Figure 1).

Hierarchy Objectives Route Applicable carbonaceous waste

(Examples) Reduce

Reuse

Recycle (Material)

Ultimate aim As much as

possible More sector

targeted solutions

From design to utilization Direct reutilization

Material recycling

not down cycling Separated & (pure) plastics Required: Chemical recycling for residue carbonaceous waste (for those not utilizable above)

Recycle (Chemical)

End of Life

Utilization As little as possible

Disposal When no other

options apply Landfill

1) Waste incineration 2) Substitute fuel (EBS)

combustion Highest

potential for closing the carbon cycle

Chemical recycling Via gasification, syngas production

and synthesis

• Mixed plastic waste

• Sorting residues

• Problematic waste (high Cl containing, shredder light fraction, carbon and glass fiber plastics, organic residues, PCB-containing, …

• Municipal waste fractions

• Municipal waste

• Different waste fractions

• Hazardous waste

• Medical waste

• …

Figure 1: Extended waste management hierarchy for carbonaceous waste

Pyrolysis/Gasification

Channeling carbonaceous waste back into the carbon cycle as feedstock for chemical production via chemical recycling is an alternative to using conventional feedstock such as oil and natural gas. Such chemical utilization of carbon waste not only increases resource efficiency, it also promotes fossil resource conservation and a cir- cular carbon economy. Furthermore, it could contribute to significantly reducing a country’s dependency on fossil imports as well as carbon leakage along the upstream value chains lying beyond national borders (like oil and natural gas imports from third countries) for its chemical production.

4. Gasification as interface technology for closing the carbon cycle

Processes and technological routes for chemical utilization of carbon resources include depolymerization (thermische Spaltung), direct liquefaction (Hydrierung) and gasification (Partialoxidation bzw. Vergasung). However, depolymerization and direct liquefaction – with carbon-based fuels as their main targeted products – do not contribute to a transition from a linear to a circular carbon economy. This is because their products will eventually be emitted into the atmosphere as CO2 fol- lowing their utilization (namely combustion for electricity, heating or mobility). In contrast, gasification – which is the thermal conversion of carbon feedstock to obtain a synthesis gas (syngas) which mainly consists of H2 and CO – is a key technology for closing the carbon cycle. Through synthesis, platform chemicals such as metha- nol can be produced from syngas and subsequently, derivates such as olefins which form the basis raw material for the production of a wide range of chemical products.

Following their utilization, the spent products can be brought back into the carbon cycle where – via gasification and the subsequent synthesis – they are converted into new chemical products again, thus closing the carbon cycle.

An overview of different gasification technologies and the advantages of gasification for chemical recycling compared to other technologies such as depolymerization and direct liquefaction are presented in [8] and [10].

5. From linear to circular carbon economy

To facilitate closing the carbon cycle and a transformation of the waste sector from a linear economy to a circular carbon economy, a coupling of the waste management, chemical and energy sectors is necessary (Figure 2).

From a thermodynamic perspective, not all of the carbon in the waste feedstock can be bonded in the chemical products. Moreover, not all chemical products will re-enter the carbon cycle as waste materials following their utilization. To illustrate, consider the case of plastics in Germany. In 2015, while 10.1 million tons of plastics are consumed, only 5.9 million tonnes came back into the system as waste for recycling [3]. This represents a gap which has to be topped up by feeding new primary carbon resources into the system for chemical production. Furthermore, plastics undergoes rapid volatilization upon heating during the gasification process. As gasification

Pyrolysis/Gasification

technology requires a certain amount of coke to guarantee a stable process, the co- gasification of carbon waste with a feedstock having a higher fixed carbon content is therefore technologically required. Last but not least, there is considerable competition on the market for carbon waste as feedstock e.g. by incinerators and as substitute fuel (Ersatzbrennstoff) for electricity and heat production. In view of these considerations and the projected release of lignite from Germany’s energy system, domestic lignite thus represents a potential and attractive partner to fulfill this role as partner for carbon waste (Figure 3).

Energy Chemical Waste

Minimized CO2 emissions

Syngas processing and chemicals synthesis

Chemical products from domestic carbon

resources Closing the Carbon Cycle

via Sector Coupling

Waste processing for chemical recycling

Green H2 from renewable electricity

Availability of domestic lignite

Gasification of carbonaceous waste

and coal

Figure 2: Closing the carbon cycle through sector coupling

Source: Lee, R. P.; Wolfersdorf, C.; Keller, F.; Meyer, B.: Towards a closed carbon cycle and achieving a circular economy for carbonaceous resources – net zero emissions, resource efficiency and resource conservation through coupling of the energy, chemical and recycling sectors. Erdöl, Erdgas, Kohle – Oil Gas European Magazine, 2017, 6:76–80

Carbon Losses

Not all chemicals products re-enter carbon cycle as waste materials after utilization

Top up this gap with domestic coal to maintain quantity of chemical production

Technological Requirement Formation of coke to support stable process for syngas production

Coal as co-feedstock with plastics support formation of coke required for a stable process

Market Competition

Strong market competition for waste as feedstock (e.g. incinerator, as substitute fuel in power plants,…)

Gap in waste resources to be met with domestic coal resources

Figure 3: Domestic coal as partner for waste in transforming from a linear to a circular carbon economy

Pyrolysis/Gasification

Additionally, to close the carbon cycle, a coupling of the waste management and chemi- cal sectors needs to be complemented with the energy sector not only for the coal input, but also for the green hydrogen. An integration of green H2 – produced via electrolysis powered by renewable energy – into the syngas could facilitate an achievement of not just zero CO2 emissions but also net zero emissions i.e. all other emissions such as heavy metals, organic and inorganic traces, fine and ultrafine particulates. Moreover, it is also possible to achieve zero liquid discharge1 along the process through waste water evaporation to obtain a concentrate.

6. Comparison of CO

2emissions

Figures 4a-c provide a simplified overview of CO2 emissions associated with the linear carbon economy where coal and carbon waste are combusted for electricity and heat in comparison to a circular carbon economy whereby they are gasified for chemical production, with and without integration of green H2.

During combustion, 100 percent of the carbon in such primary and secondary carbon car- riers are emitted into the atmosphere as CO2 (Figure 4a). In Germany, under the current EU Emissions Trading System (ETS), CO2 emissions by fossil power plants face an ETS penalty whereas those emitted from waste incineration enjoy ETS allowances (that me- ans, they face no penalty payment). Despite this differentiation in ETS penalties between CO2 emissions from different sources, the combustion of 100 units C (carbon atoms) of lignite and 100 C of waste in Germany for electricity and heat will nevertheless result in 200 C being released as CO2.

1 Zero Liquid Discharge (ZLD) is defined under strict conditions as a complete reduction of the water volume, with water leaving the system only in the form of steam and solids are recycled or separated in dry form. Under restricted conditions, no waste water leaves the system but sludge, brine, aerosols or water by leaching [5]

Carbon Waste

Lignite 100 C

100 C

100 C 100 C CO2 CO2

ETS* penalty ETS* allowance *Emissions Trading System

Electricity and Heat Electricity and Heat Waste Incinerator

Coal Power Plant

Figure 4a: Combustion without sector coupling (Status Quo)

In the mid-term (that is 2025), a coupling of the energy with waste and chemical sec- tors in the form of conventional chemical utilization already supports the transition from a linear to circular carbon economy. As can be seen in Figure 4b, even with the utilization of lignite as a co-feedstock for gasification, the majority of the carbon in the primary and secondary carbon carriers are bonded in the chemical products (104 C), resulting in reduced CO2 emissions (96 C) compared to the combustion of waste and lignite as illustrated above (200 C).

Pyrolysis/Gasification Figure 4b: Conventional chemical utilization with sector coupling (Scenario 2025+)

In the long term (that is 2050+), with an integration of green H2 – a probable scenario considering the projected surplus of renewable electricity resulting from Germany’s Energiewende – it is possible to achieve net zero emissions via the interface techno- logy gasification (Figure 4c). This will represent a milestone in efforts to achieve a closed carbon cycle whereby 100 percent of carbon in waste feedstock can be bonded into the chemical products, thus resolving the problem of feedstock carbon losses.

Additionally, technological innovations and further developments could potentially support the mono-gasification of waste, thus eliminating the technological requirement for a coke delivering partner. Furthermore, in focusing on specific waste segments which are challenging for combustion such as high calorific as well as problematic waste (for example high Cl containing, shredder light fractions, carbon and glass fiber plastics, composites), chemical recycling could be a valuable partner for waste incinerators, thus addressing the market competition problem.

Carbon Waste Lignite

100 C 100 C

96 C**

104 C**

CO2

*based on process chain calculations

Chemical products with

~ 50 % recycled carbon content (Methanol to Olefin) Sector coupling

with reduced CO2 emissions

Carbon Waste Lignite

100 C 100 C

200 C 0 C

green H2 CO2

Chemical products with

~ 100 % recycled carbon content (Methanol to Olefin) Sector coupling

WITHOUT CO2 emissions

Figure 4c: Future chemical utilization with sector coupling (Scenario 2050+)

7. Case analysis – emissions free olefin production with domestic carbon feedstock

In the long term perspective (that is Scenario 2050+), all carbonaceous waste streams (CO2 emissions, carbon components in purge gases and others) must be recycled.

Sufficient amount of green H2 thus need to be produced so as to bond all waste carbon atoms into the chemical products. A central criterion for technology development and implementation would thus be the minimal demand for green H2 to produce emissions free chemical products.

Pyrolysis/Gasification

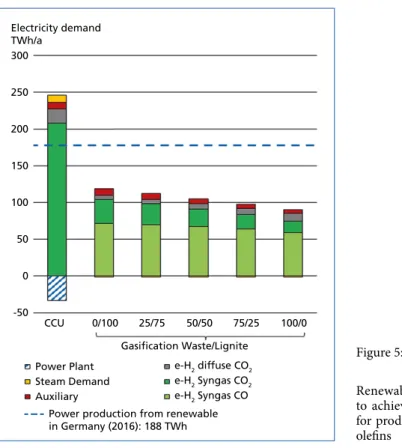

To illustrate the demand on renewable electricity in order to achieve zero CO2 emis- sions, our case analysis focuses on olefin production in Germany. Olefins, especially ethylene and propylene, form the largest group of chemical intermediates (especially for plastic production). Up till now, imported crude oil plays a predominant role as carbon feedstock for Germany’s production of organic basic chemicals such as olefins.

In view of current developments and the potential presented by a coupling of the energy, chemical and waste sectors, we evaluate two alternative technological routes for replacing imported crude oil with domestic carbon resources for the production of 10 million t/a of olefins (which roughly amounts to Germany’s annual production in 2015). The two technological routes are namely:

• Carbon Capture and Utilization (CCU) – In this scenario, we assume that all carbon waste streams from the incineration of plastic waste in Germany are captured and bonded into chemical products through the integration of green H2. In this scenario, we assume that there is enough plastic waste available to support the production of 10 million t/a of olefins.

• Gasification – To illustrate the renewable electricity demand to achieve zero CO2 emissions via the interface technology gasification, we base our evaluations on the COORVED2 (CO2 reduction by innovative gasifier design) gasifier technology. The amount of renewable electricity required to produce sufficient green H2 to ensure zero CO2 emissions is determined for different combinations of waste and lignite for olefin production.

A detailed description of methods, evaluation parameters and assumptions for the evaluation of alternative technological routes is described in [9]. Selected results are presented here.

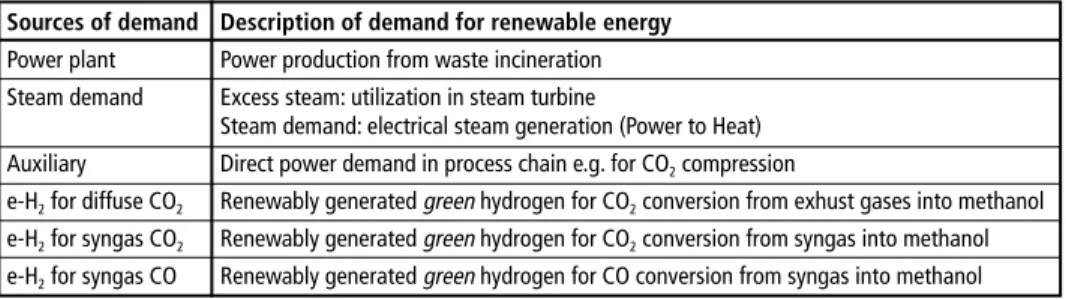

Table 1 presents a description of where renewable energy is required (and produced in the case of waste incineration) in the production process, both for general operation as well as for producing green hydrogen for integration in the syngas (CO2 and CO) and exhausted gases (so-called diffuse CO2) so as to bond all waste carbon into the chemical products.

2 For an overview of the COORVED gasification technology, please refer to [12, 15]

Table 1: Sources and description of demand for renewable energy Sources of demand Description of demand for renewable energy Power plant Power production from waste incineration Steam demand Excess steam: utilization in steam turbine

Steam demand: electrical steam generation (Power to Heat) Auxiliary Direct power demand in process chain e.g. for CO2 compression

e-H2 for diffuse CO2 Renewably generated green hydrogen for CO2 conversion from exhust gases into methanol e-H2 for syngas CO2 Renewably generated green hydrogen for CO2 conversion from syngas into methanol e-H2 for syngas CO Renewably generated green hydrogen for CO conversion from syngas into methanol

Pyrolysis/Gasification

Figure 5 illustrates the model evaluation results for the quantity of renewable energy required to achieve zero CO2 emissions. In our evaluations, we assume a 70 percent efficiency for the water electrolysis to produce green hydrogen.

Electricity demand TWh/a

300

250

200

150

100

50

0

-50

Power production from renewable in Germany (2016): 188 TWh Power Plant

Steam Demand Auxiliary

e-H2 diffuse CO2 e-H2 Syngas CO2 e-H2 Syngas CO

CCU 0/100 25/75 50/50 75/25 100/0 Gasification Waste/Lignite

Figure 5:

Renewable electricity demand to achieve zero CO2 emissions for producing 10 million t/a of olefins

We observed that the electricity demand is significantly dominated by the supply of green hydrogen. Compared to gasification, the demand for renewable electricity in the CCU scenario is significantly higher in order to achieve zero CO2 emissions. Specifically, the amount of renewable electricity required to close the carbon cycle for producing 10 million t/a of olefins via CCU is higher than Germany’s current renewable genera- tion of 188 TWh in 2016 [1]. Strikingly, the amount of electricity which is generated via waste incineration (i.e. power plant) is only a small proportion compared to the amount of renewable electricity which is needed to close the carbon cycle with the CCU alternative. Moreover, efforts which are required to address other emissions from the incineration process (e.g. heavy metals, fine particulate etc.) so as to achieve net zero emissions still need to be considered.

In the case of sector coupling via gasification for the production of 10 million t/a of olefins, the innovative COORVED gasification technology requires considerably less green H2 to achieve zero CO2 emission compared to CCU. Furthermore, gasification technology has the advantage that it could achieve net zero emission for chemical

Pyrolysis/Gasification

production. By increasing the plastic waste content for gasification, the hydrogen con- tent in the syngas increases due to the higher H/C ratio, thus lowering the demand for green hydrogen via electrolysis.

While mono-gasification using only plastic waste as feedstock is highly desirable in terms of increasing carbon resource efficiency and fossil resource conservation, such technology is currently not yet mature for widespread and large-scale applications.

Examples of pilot scale applications for near atmospheric waste gasification exist in Japan [14] and Canada [11]. In Germany, industrial application of large-scale pressurized gasification of carbonaceous waste together with coal has been successfully carried out in Berrenrath (till 1997) and Schwarze Pumpe (till 2007), both for the production of methanol – an important basic chemical used for the production of other value- added chemical products. However, diverse reasons ranging from the significant costs associated with running and maintaining such plants, the low prices acquired by methanol on the market, to the recognition of energetic waste utilization as a form of accepted recycling in the late 1990s have resulted in the cease of operations of these gasification plants as they were unable to compete economically under the existing regulatory and market conditions [13].

8. Limitations & directions for future research

In this article, we have presented evaluations based on the assumptions that chemical (olefin) production from conventional oil imports in Germany is completely replaced by domestic carbon sources (that is CO2 from waste incineration in the CCU scena- rio, and waste and coal in the gasification scenario), and that there is enough plastic waste available to support the production of 10 million t/a of olefins. However, the availability of plastic waste – 5.9 million tonnes are currently available for recycling [3]

but over 10 million tonnes would be required to fully replace conventional feedstock for olefin production in Germany – is a bottleneck which makes the use of plastic as a chemical feedstock highly challenging. Moreover, plastic waste, in particular sepa- rated and pure plastics, are highly suitable for material recycling. Hence, in the waste hierarchy (refer to Figure 1), such alternative utilization of plastics would be favored to its chemical utilization.

In the next steps, we aim to assess the actual potential of plastic waste – in terms of availability as well as market competition for alternative utilization – as feedstock for the chemical industry. Furthermore, other types of waste (in terms of quantities, car- bon content, current form of utilization/recycling and others) will also be evaluated to determine the potential for chemical recycling in Germany. Last but not least, location- specific requirements and parameters for a commercial-scale facility at one million t/a of olefins will be analyzed to support the assessment of the feasibility of using domestic carbon resources for chemical production in Germany.

Pyrolysis/Gasification

9. Conclusion

To conclude, through a coupling of the energy, chemical and waste management sectors via the interface technology gasification, it would be possible to achieve:

(1) net zero emissions (that means not only for GHG emissions but also for rest emis- sions such as heavy metals, organic and inorganic traces, fine particulates) via ga- sification and integration of renewably generated hydrogen,

(2) resource efficiency through chemical recycling instead of incineration (namely transformation from linear to circular carbon economy), and

(3) resource conversation whereby carbon waste is used as a feedstock for chemical production instead of oil or natural gas.

Besides contributing to reducing Germany’s total CO2 emissions, resolving global waste problem as well as conserving natural resources, other advantages and motivation for using domestic primary (namely lignite) and secondary (namely waste) carbon resour- ces as alternative feedstock for the chemical industry in Germany include reducing import dependency for chemical production, reducing carbon leakage along upstream international carbon value chains, supporting sustainable structural change in lignite mining regions in Germany, and promoting technological leadership in the field of chemical waste recycling among others.

However, although there are various advantages for closing the carbon cycle via sector coupling, in the past, unfavorable regulatory and market conditions as well as high costs have contributed to the demise of industrial applications (like Berrenrath and Schwarze Pumpe) in Germany. In the meantime, political pressure – especially the increasing focus on achieving a circular economy in addition to the energy transition – is setting new demands on carbon intensive industries to take steps to achieve lower emissions, higher resource efficiency and conservation of natural resources. However, regulatory and legal frameworks in their current forms do not sufficiently support efforts to meet these challenging objectives. As such, regulations and incentives will have to be adapted and/or developed so that such efforts at closing the carbon cycle via sector coupling will be competitive to existing routes of energetic waste utilization and import depen- dent fossil-based chemicals production [8]. In addition, widespread acceptance in the society (for example by the politics, local communities as well as by market players) is also necessary to support a successful and sustainable transformation from a linear to a circular carbon economy [6, 7].

10. Literature

[1]. AEE, Agentur für Erneuerbare Energie: Strommix in Deutschland 2015. https://www.unendlich- viel-energie.de/mediathek/grafiken/der-strommix-in-deutschland-im-jahr-2016. Accessed December 12, 2016

Pyrolysis/Gasification

[2] BMUB: Federal Ministry for Environment, Nature Conservation, Building and Nuclear Safety.

(2012). Gesetz zur Förderung der Kreislaufwirtschaft und Sicherung der umweltverträglichen Bewirtschaftung von Abfällen. http://www.gesetze-im-internet.de/bundesrecht/krwg/gesamt.

pdf. Accessed February 5, 2017

[3] Consultic. (2016): Produktion, Verarbeitung und Verwertung von Kunststoffen in Deutsch- land 2015 – Kurzfassung. http://www.bkv-gmbh.de/fileadmin/documents/Studien/Consultic _2015__23.09.2016 __Kurzfassung.pdf. Accessed 10.10.2016

[4] DEBRIV. (2016): Lignite in Germany 2015 Facts and Figures. Accessed 02.06.2016.

[5] DECHEMA e.V. (2015): Potential of zero liquid discharge (ZLD) in industrial water manage- ment. http://dechema.de/dechema_media/Diskussionspapier_ZLD_2015_engl-p-20001670.

pdf. Accessed May 5, 2017

[6] Lee, R. P.; Keller, F.; Meyer, B.: A closed carbon cycle through sector coupling? Challenges posed by path dependency in the socio-technical system. 8th International Conference on Clean Coal Technologies, 8th-12th May, Cagliari, Italy, 2017

[7] Lee, R. P.; Reinhardt, R.; Keller, F.; Gurtner, S.; Schiffer, L.: A raw materials transition for a low- carbon economy: Challenges and opportunities for management in addressing the trilemma of competitiveness, supply security and sustainability. In George G.; Schillebeeckx, S.J.D. (eds.) Managing Natural Resources: Organizational Strategy, Behavior and Dynamics, Edward Elgar Publishing, London, UK. (Forthcoming), 2017

[8] Lee, R. P.; Wolfersdorf, C.; Keller, F.; Meyer, B.: Towards a closed carbon cycle and achieving a circular economy for carbonaceous resources - net zero emissions, resource efficiency and resource conservation through coupling of the energy, chemical and recycling sectors. Erdöl, Erdgas, Kohle – Oil Gas European Magazine, 2017, 6:76–80

[9] Meyer, B.; Keller, F.; Wolfersdorf, C.; Lee, R. P.: Ein Konzept für die Kohlenstoffkreislaufwirt- schaft. Sektorkopplung von Energie, Chemie & Abfall. Chemie, Ingenieur, Technik. Submitted in July 2017

[10] Meyer. B.; Wolfersdorf, C.; Keller, F.; Lee, R.P.: Anforderungen an Technologien zur stoffli- chen Nutzung von Braunkohlen als Baustein der Energiewende – vollständige Schließung des C-Kreislaufs durch CO2-emissionsfreie Kohlechemie. DGMK-acatech Workshop, 19.10.2016, Berlin, Germany

[11] Miles, A.: Enerkem biorefineries: setting a new global standard in biofuels, chemicals and waste management. https://www.nepic.co.uk/wp-content/uploads/2016/09/AlexMiles-ENERKEM.

pdf. Accessed November 2, 2016

[12] Schimpke, R.; Laugwitz, A.; Schurz, M.; Krzack, S.; Meyer, B.: Flow pattern evaluation of the internal circulation gasifying principle. Fuel, 2015, 147:221-229

[13] Schmalfeld, J. (ed): The processing and conversion of coal – Technologies and projects 1970 to 2000 in Germany. DGMK Deutsche Wissenschaftliche Gesellschaft für Erdöl, Erdgas und Kohle e.V., Germany, 2008

[14] thyssenkrupp Industrial Solutions: Gasification technologies. https://www.thyssenkrupp- industrial-solutions.com/media/products_services/chemical_plants_processes/gasification/

tkis_gasification_technologies.pdf. Accessed March 13, 2014

[15] Wolfersdorf, C.; Meyer, B.: The current status and future prospects for IGCC systems. In: Wang T, Stiegel GJ (eds) Integrated gasification combined cycle (IGCC) technologies. Woodhead Pub- lishing, Duxford, Cambridge, Kidlington, 2017

Bibliografische Information der Deutschen Nationalbibliothek Die Deutsche Nationalbibliothek verzeichnet diese Publikation in der Deutschen Nationalbibliografie; detaillierte bibliografische Daten sind im Internet über http://dnb.dnb.de abrufbar

Thomé-Kozmiensky, K. J.; Thiel, S.; Thomé-Kozmiensky, E.;

Winter, F.; Juchelková, D. (Eds.): Waste Management, Volume 7 – Waste-to-Energy – ISBN 978-3-944310-37-4 TK Verlag Karl Thomé-Kozmiensky

Copyright: Elisabeth Thomé-Kozmiensky, M.Sc., Dr.-Ing. Stephanie Thiel All rights reserved

Publisher: TK Verlag Karl Thomé-Kozmiensky • Neuruppin 2017

Editorial office: Dr.-Ing. Stephanie Thiel, Elisabeth Thomé-Kozmiensky, M. Sc.

Janin Burbott-Seidel and Claudia Naumann-Deppe

Layout: Sandra Peters, Anne Kuhlo, Ginette Teske, Claudia Naumann-Deppe, Janin Burbott-Seidel, Gabi Spiegel and Cordula Müller

Printing: Universal Medien GmbH, Munich

This work is protected by copyright. The rights founded by this, particularly those of translation, reprinting, lecturing, extraction of illustrations and tables, broadcasting, micro- filming or reproduction by other means and storing in a retrieval system, remain reserved, even for exploitation only of excerpts. Reproduction of this work or of part of this work, also in individual cases, is only permissible within the limits of the legal provisions of the copyright law of the Federal Republic of Germany from 9 September 1965 in the currently valid revision. There is a fundamental duty to pay for this. Infringements are subject to the penal provisions of the copyright law.

The repeating of commonly used names, trade names, goods descriptions etc. in this work does not permit, even without specific mention, the assumption that such names are to be considered free under the terms of the law concerning goods descriptions and trade mark protection and can thus be used by anyone.

Should reference be made in this work, directly or indirectly, to laws, regulations or guide- lines, e.g. DIN, VDI, VDE, VGB, or these are quoted from, then the publisher cannot ac- cept any guarantee for correctness, completeness or currency. It is recommended to refer to the complete regulations or guidelines in their currently valid versions if required for ones own work.