We Are Closing the Cycle:

Your Expert Partner for Thermal and Biological Energy-from-Waste Plants

Our solutions are based on effi cient and environmentally sound in-house technology, and cover the entire life cycle of an Energy-from-Waste facility. Our proven technologies have been part of more than 700 plants worldwide. As a global leader in energy from waste we are proud to be able to say:

We deliver. Check our references.

Waste is our Energy www.hz-inova.com

HZI_Anzeige_Image_Unternehmen_Anlage_155x235_EN_RZ.indd 1 02.06.17 13:58

319 Opportunities for CO2 Capture in the Waste-to-Energy Sector

Waste Incineration

Opportunities for CO

2Capture in the Waste-to-Energy Sector

Mario Ditaranto, Michaël Becidan and Johnny Stuen

1. Potential of CCS applied to the Waste-to-Energy sector ...319

2. The Oxy-Fuel Combustion Capture Technology ...321

3. Challenges and benefits ...325

4. Objectives of CapeWaste ...326

5. Conclusion ...327

6. Literature ...327 The highest probability scenario for limiting global warming to 1.5 °C necessitates to reach net zero CO2 emissions by 2040 according to the 2019 IPCC Special report on Global Warming of 1.5 °C. There are many pathways to achieve that target depending on the global energy mix, i.e. the degree of fossil fuel to be used, the share of renewable energy, the growth of energy demand, etc. The Energy Technology Perspectives 2017 of the International Energy Agency estimate that fossil fuel based energy with CO2 Capture and Storage (CCS) will have to contribute by more than 20 % of the CO2 reduction effort by the mid-century. All IPCC scenarios leading to a 1.5 °C increase involve some degree of Carbon Dioxide Removal (CDR) from the atmosphere. Bioenergy with CCS – so called bio-CCS or BECCS – is the technology having highest potential for realising CDR at an appreciable scale. Of the different mitigation strategies leading to that goal, avoiding bio-CCS would require that the renewable energy share in electricity produc- tion be 60 % by 2030 and further 77 % by 2050. By comparison this share was 25 % in 2017, therefore this scenario is quite ambitious and any lower renewable share would require a growing part of Bio-CCS. Because Municipal Solid Waste (MSW) contains a varying degree of biogenic carbon, application of CCS to Waste-to-Energy plants is a bio-CCS measure and allows this technology to remove carbon dioxide from the atmosphere. CO2 Capture and Storage is one of Norway’s priority areas to achieve its Intended Nationally Determined Contribution for targeting at least 40 % reduction of greenhouse gas emissions by 2030 compared to 1990 levels. The present article focuses on the potential for applying CCS to greenfield Waste-to-Energy plants by means of the innovative oxy-fuel combustion capture technology.

1. Potential of CCS applied to the Waste-to-Energy sector

Historically, CCS has focussed on the power sector and specifically on coal. Today, not only is it accepted that this is not sufficient, but industrial CO2 emissions appear to be equally important. All industries have become potential CCS players and the

Mario Ditaranto, Michaël Becidan, Johnny Stuen

320

Waste Incineration

Waste-to-Energy sector is very interesting in that respect for Norway as it is one of the largest land-based CO2 emitter. Beyond Norway, the potential is large worldwide.

Indeed, according to the Confederation of European Waste-to-Energy Plants (CEWEP), 88.4 Mt of waste were thermally treated in Europe in 2014 in 455 plants, generating 38 TWh of electricity and 88 TWh of heat and corresponding to an equal amount of CO2 emissions being emitted to the atmosphere (IPCC methodology). There is an equivalent amount of waste being landfilled in the EU, with shares in the national waste landscapes varying greatly from 1 % to 90 %. Hence, there is a large potential for applying CCS to both retrofit and greenfield commercial plants in the Waste-to- Energy sector. Worldwide, the potential is much larger, particularly in very populated countries with high growth rates. For example, China had 223 Waste-to-Energy plants at the end of 2015 with plans to double that figure in the near future and the amount of energy recovered waste is expected to increase to 500,000 tons per day by 2020 [8].

Also, the Waste-to-Energy sector has so far been overlooked as a candidate for CCS and technologies have mainly focused on the fossil fuel-based power and energy intensive industry sectors. In short, Waste-to-Energy is one of the few industrial sectors stron- gly growing worldwide, but is in need of research and development to answer specific questions related to the application of capture technologies in these types of plants.

Implementing CCS to Waste-to-Energy is a societal engagement by further improving its a climate-friendly impact. Indeed, capturing and storing CO2 comes at an added cost which is no less than the cost of maintaining a viable planet. Research in CCS science and technology strives to reduce the costs of hardware and that of operation, the so- called efficiency penalty. The business model has been lacking for the deployment of CCS, but industrial actors willing to take a head start will be able to take larger share of the market when it opens up. It is worth noting that CCS applied to the waste sector could attract support from stakeholders in the same way that CCS does in heavy in- dustries. The Waste-to-Energy sector is not included in EU Emissions Trading System (ETS) and will not have access to flexible mechanisms and possibilities within ETS. To follow-up the EU targets (40 % and 80 % reduction by 2030 and 2050), cuts will have to be taken by the sector itself, making CCS a necessary solution.

CO2 storage CO2 use

CO2 heat

electricity

waste Waste-to-Energy

plant with CO2 capture

Figure 1: The environmentally sound Waste-to-Energy cycle with negative CO2 emissions

321 Opportunities for CO2 Capture in the Waste-to-Energy Sector

Waste Incineration

Even though Waste-to-Energy plants were originally placed near large cities to take care of the locally produced waste, the situation has changed and the market is now international. For example, the Oslo Klemetsrud plant burns 70,000 tons of British imported residual waste per year. The competition for raw waste materials can be fierce and the potential for a plant owner to burn waste with a negative CO2 emission credits (provided an appropriate framework be enforced) can be both a profitable and give a unique position with regard to its competitors.

2. The Oxy-Fuel Combustion Capture Technology

Capturing CO2 at where it is generated, i.e. where the fuel is consumed, and permanently storing it is a very effective and rapid way to reduce its emission in the atmosphere as compared to natural uptake processes. There are three main technology pathways for Carbon Capture and Storage (CCS): post-combustion capture – where a CO2 separation process is installed at the back end of the power plant; pre-combustion capture – which necessitates the implementation of a fuel gasification or reformer process and a hydro- gen rich combustion system; and oxy-fuel combustion capture – requiring an adapted combustion system for burning in pure oxygen instead of air and large concentration of CO2, as well as an ASU to produce pure oxygen or transport of oxygen to the site.

For existing plants the post-combustion approach is well-suited with the advantages of minimum impact on the existing power island, the chemical process is mature, it minimizes the risk of introducing a new incineration technology, and gives the owner the possibility to bypass or shut down the capture plants without disrupting the waste incineration process. The implementation of such a technology was confirmed by the feasibility and concept study targeted to the Klemetsrud Waste-to-Energy plant in Oslo, where pilot tests based on an amine separation process were concluded and resulted in a nearly 90 % capture rate [3].

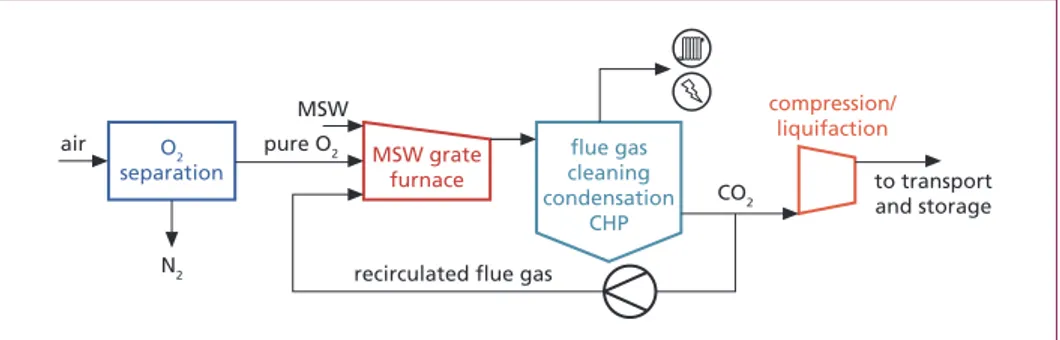

Innovative technology may however offer better solution in terms of efficiency, integ- ration and combustion process. The technology considered in the CapeWaste project is the oxy-fuel combustion depicted in Figure 2. The target of all CCS technologies is the generation of a CO2-rich gas stream that can be stored or used for other processes.

To generate a concentrated CO2 volume flow with a simple and low-cost separation, the oxy-fuel combustion takes place with pure oxygen instead of air. By preventing the presence of nitrogen in the furnace, the proportion of CO2 in the flue gas is drastically increased and its separation is in theory simply made by the condensation of steam. The adiabatic flame temperature is however much higher in the presence of pure oxygen than in conventional air, therefore a significant recirculation of the dry or wet flue gas (composed of CO2 and steam) is necessary to avoid excessive temperatures without affecting the efficiency of the CO2 processing. The volume of gases escaping the com- bustion chamber is also reduced and must be accounted for in the heat exchanger part of the CHP plant. As a consequence other minor species that must be treated such as NOx, SOx, and other regulated pollutants can be present at higher concentrations even though not necessarily at higher amounts.

Mario Ditaranto, Michaël Becidan, Johnny Stuen

322

Waste Incineration

The oxy-fuel CO2 capture route is a technology that has received considerable attention during the last decade. The power sector has extensively investigated the feasibility of pulverized coal oxy-fuel boilers in pilot plants with a thermal output of up to 30 MWel (Schwarze Pumpe pilot plant in Germany, Lacq project in France, Callide project in Australia, and Hubei in China). These tests at industrial pilot scale have demonstrated the technical feasibility of this CO2 capture route for a variety of coal qualities, burner and furnace configurations. A considerable amount of fundamental data and enginee- ring experience is therefore available all along the CO2 chain, from the Air Separation Unit (ASU) producing the oxygen stream to the CO2 compression. A good summary of lessons learned from investigations and the operation of the aforementioned pilots can be found in Stanger et al. [9]. The oxy-fuel technology has been qualified and allowed to prepare the FEED study of three commercial demonstration plants: Jänschwalde, White Rose, and FutureGen 2. Unfortunately, all of these have been cancelled due to lack of acceptance for CO2 storage for the former and withdrawal of public funding for the other two.

air

MSW

MSW grate furnace

flue gas cleaning condensation

CHP

compression/

liquifaction

to transport and storage recirculated flue gas

O2 separation

CO2 pure O2

N2

Figure 2: General scheme of the oxy-fuel capture process

Much less has been investigated with respect to the integration of oxy-combustion in waste grate incinerators. Laboratory and techno-economic analysis of waste combustion found in the literature have been performed for oxygen-enriched combustion (OEC) conditions [4, 10]. These studies report a better combustion as well as lower NOx and SO2 emissions compared to O2/N2 ambient combustion. Tang et al. [11] even showed using LCA of oxy-fuel MSW in China that it has both better efficiency and environmental impacts than MEA post-combustion. Apart from these process assessments, there is a real lack of data on MSW combustion properties under oxy-fuel firing conditions that the CapeWaste project aims at providing experimentally through the use of dedicated reactors. These data are critical in order to build reliable combustion modelling tools, necessary to develop and scale up of grate furnaces. The question of air leakage is also critical in the context of MSW furnaces because of the nature of MSW and the feeding systems. The presence of nitrogen must be avoided because it impacts the separation process. However, how much leakage must be avoided is not known. The effect of oxygen purity on a coal-fired oxy-fuel power plant has a sweet point between purity (i.e., cost of O2 production) and loss in the cryogenic CO2 Processing Unit [6], such studies are lacking for Waste-to-Energy.

STANDARDKESSEL BAUMGARTE - Power plants, plant operation and services for generating electricity, steam and heat from residues, primary fuels, waste heat and biomass.

Energy costs are continually rising. Making it all the more important for companies and municipalities to explore cheaper fuel alternatives for their energy supply.

We are experts in them: household and commercial waste, industrial residues and refuse derived fuels. And for many years now, we have been proving how they can be used in thermal recycling processes to produce useable energy for generating electricity, process steam and district heat.

For more information and references, visit:

www.standardkessel-baumgarte.com

TONS OF ENERGY!

ENERGY GENERATION FROM RESIDUES:

EFFICIENT & ECO-FRIENDLY.

SBENG_IRRC_Wien.indd 1 14.05.2019 09:06:42

325 Opportunities for CO2 Capture in the Waste-to-Energy Sector

Waste Incineration

Th e Waste-to-Energy plant manufacturer Martin GmbH has patented a grate incine- rator concept called SYNCOM with similar characteristics as the oxy-fuel technology.

Th e process consists of a reversed grate-based system fi red with oxygen-enriched air and a gas recirculation circuit. Th is technology has proven to optimize the combustion process, reduce the fl ue gas fl ow and minimize pollutant emissions. However, in oxy- fuel combustion for capture application, all the air is replaced by recycled fl ue gas, i.e.

CO2 and steam, aff ecting the combustion and heat transfer properties of the entire furnace. Th erefore, further development is needed to optimize the furnace technolo- gy. Th e ASU constitutes most of the energy penalty incurred by an oxy-fuel capture process. Th anks to the growing interest in CO2 capture technologies, they have seen considerable improvement in the last 20 years and are still expected to gain another 10 – 15 %-points effi ciency [7] in the coming decade. Potential breakthrough in oxygen membrane technology would further reduce the energy penalty. At the other end of the CO2 capture chain, the CO2 processing unit (CPU) has been proven to be very effi cient by combining compression and pollutants cleaning (NOx, SOx) in integrated unit [12].

3. Challenges and benefi ts

Implementing an innovative technology such as oxy-fuel combustion capture to a Waste-to-Energy plant requires to follow an innovation track consisting of: 1) the adaptation of CCS to MSW and Waste-to-Energy conditions, 2) the optimization of the energy integration of CCS and MSW combustion, and 3) a process analysis to provide a trustable basis for a FEED study. Th e only applications of CO2 capture tech- nology to Waste-to-Energy plants, as known by the authors, are the pilot testing done at the Klemetsrud plant in Oslo (Norway) [3] where a 1 % side stream of fl ue gases were captured using solvents (without energy integration), the pilot tests at Twence Hengelo in the Netherlands and the planned Saga City project in Japan [5]. Climate change and waste management are societal challenges that both have high priority as demonstrated by the fi rst universal climate agreement adopted by 195 countries at the Paris COP21 in 2016, as well as the EU action plan for the Circular Economy Package [1]. In this package, clear targets are set on waste management and recycling to develop a sustainable, low-carbon, resource-effi cient and competitive economy in the future.

Aft er material recovery, energy recovery from the non-recyclable part of waste/MSW logically fi nds its role by producing renewable heating, cooling and electricity, and is thus compatible with the 7th Environment Action Programme [2] aiming at phasing out landfi lling in Europe (the fate of about 100 million tons MSW each year), and to develop a resource-effi cient, green, and competitive low-carbon economy. Enabling CCS in the Waste-to-Energy sector has therefore a potential for European innovation and job creation, and because of the mostly local nature of the service provided (waste management), this is a sector with a low risk of industry leakage to low-wages regions.

Importantly, Waste-to-Energy plants represent an opportunity for removing CO2 from the atmosphere. Indeed, 33 % to 60 % of MSW is of biogenic origin, making CCS from Waste-to-Energy a carbon negative technology. As noted previously most scenarios leading to a limited global temperature increase requires negative GHG emissions.

Mario Ditaranto, Michaël Becidan, Johnny Stuen

326

Waste Incineration

Besides, it provides opportunities for the plant owner to sale CO2 quotas, constituting an incentivizing rewarding system, and for the communities to compensate for GHG emissions from other sectors which may be more difficult or expensive to reduce. Finally, introducing CCS at municipal service level takes CCS closer to the general public, a key aspect for the widespread development of this technology and increase the public acceptance challenge that CCS has suffered from.

From a technological point of view, oxy-fuel combustion can bring benefit to the incinera- tion process in that it allows real time zonal temperature control in the furnace. In air, the flame temperature is limited by the presence of nitrogen, for example the maximum adi- abatic temperature with methane as the fuel is around 2,200 K whereas it reaches 3,050 K in pure oxygen. Therefore, by using a well-designed oxygen distribution the furnace could accommodate in real time any process fluctuations or inhomogeneities of the fuel.

4. Objectives of CapeWaste

If the City of Oslo is to keep on track with the goal of reducing its CO2 emissions by 95 % by 2030, all new Waste-to-Energy plants will need to consider CO2 capture. A greenfield plant gives the opportunity to consider an advanced capture technology which is better integrated to the plant. Knowledge and assessment of such technolo- gies applied to the field of Waste-to-Energy must therefore be available for making the right technology choice. The current CapeWaste project fills in this knowledge gap and provides the basis for a pre-FEED study of an oxy-fuel Waste-to-Energy plant with CO2 capture, through:

1. Characterization of the combustion behaviour of MSW fractions in oxy-fuel at- mospheres;

2. Development and validation of combustion model for MSW in oxy-fuel atmo- spheres;

3. Simulation and optimization of a full scale oxy-MSW furnace;

4. Establishment of an optimal oxy-fuel Waste-to-Energy plant setup.

Due to its non-homogenous and varying nature, waste as a feedstock is a challenging fuel for CO2 capture technologies requiring that close-to-market technologies be assessed in relevant industrial environments. A number of issues related to the combustion and gasification of these challenging fuels are yet to be resolved. To name some examples:

the quality of bottom and fly ash and air leakages in the fuel feeding system. In addi- tion to fuel-related challenges, implementation of CCS into Waste-to-Energy plants needs careful consideration, where sizing, optimization of capture installations, and heat integration are all important aspects to be investigated in order to optimise the economics of scale of these processes. Process simulations will assess the performance of the full-scale oxy-fuel Waste-to-Energy plant, including other components like the CO2 processing unit. These activities will all be based on the Haraldrud (Oslo) Waste- to-Energy plant model.

327 Opportunities for CO2 Capture in the Waste-to-Energy Sector

Waste Incineration

5. Conclusions

There is a large potential for applying CO2 capture to Waste-to-Energy plants allowing for carbon negative emissions due to its biogenic carbon content of the fuel. Although a low risk strategy would be to apply an established post-combustion capture process, a greenfield plant, which many are planned in the near future, is an opportunity to develop more integrated capture process for better efficiency and improved process characteristics. Such a technology is the oxy-fuel combustion capture based on the use of pure oxygen and recirculation of the flue gases in the furnace. The CapeWaste project aims at providing both new combustion data necessary to design the furnace and optimize the process based on a Norwegian Waste-to-Energy model.

Acknowledgements The authors are grateful to the Research Council of Norway for supporting this project under CLIMT program grant nr. 629364 and the project partners: EGE AS, AGA AS, and Miljødirektoratet.

6. Literature

[1] European Commission: Closing the loop – An EU action plan for the Circular Economy (COM/2015/0614 final), 2015

[2] European Commission: Decision No 1386/2013/EU European Parliament and Council of 20/11/2013 on a General Union Environ. Action Programme, 2013

[3] Fortum Oslo Varme – Klemetsrudanlegget (KEA) – Carbon Capture Oslo.: Concept Study Re- port, 06.03.2018

[4] Fu et al.: MSW oxy-enriched incineration technology applied in China, Waste Management 2014.12.026, 2015

[5] IEA: Information Paper 2016-IP43

[6] Li et al.: Optimization of Cryogenic CO2 Purification for Oxy-coal Combustion, Energy Procedia 37:1341, 2013

[7] Perrin et al.: Latest performances and improvement perspective of Oxycombustion, Energy Procedia 2014.11.057, 2014

[8] Reuters: http://www.reuters.com/article/us-china-power-waste-idUSKBN1390B7

[9] Stanger et al. : Oxyfuel combustion for CO2 capture in power plants, Int. J GHG Control DOI:

10.1016/j.ijggc.2015.06.010, 2015

[10] Tang et al.: NOx and SO2 emissions from MSW combustion in CO2/O2 atmosphere, Energy 2012.01.070, 2012

[11] Tang et al.: Energy analysis and environmental impacts of a MSW …, Ener. Pol. 2013.04.073, 2013

[12] White et al.: Purification of oxyfuel-derived CO2, Int J Greenh Gas Contr.2009.07.004, 2010

Mario Ditaranto, Michaël Becidan, Johnny Stuen

328

Waste Incineration

Contact Person

Dr. Mario Ditaranto SINTEF Energi AS Senior Research Scientist Thermal Energy

Kolbjørn Hejesvei 1A 7034 Trondheim NORWAY

mario.ditaranto@sintef.no

Other institutions involved

Energigjenvinningsetaten – Oslo kommune (EGE)

Vorwort

4

Bibliografische Information der Deutschen Nationalbibliothek Die Deutsche Nationalbibliothek verzeichnet diese Publikation in der Deutschen Nationalbibliografie; detaillierte bibliografische Daten sind im Internet über http://dnb.dnb.de abrufbar

Thiel, S.; Thomé-Kozmiensky, E.; Winter, F.; Juchelková, D. (Eds.):

Waste Management, Volume 9 – Waste-to-Energy –

ISBN 978-3-944310-48-0 Thomé-Kozmiensky Verlag GmbH

Copyright: Elisabeth Thomé-Kozmiensky, M.Sc., Dr.-Ing. Stephanie Thiel All rights reserved

Publisher: Thomé-Kozmiensky Verlag GmbH • Neuruppin 2019 Editorial office: Dr.-Ing. Stephanie Thiel, Elisabeth Thomé-Kozmiensky, M.Sc.

Layout: Claudia Naumann-Deppe, Janin Burbott-Seidel, Sarah Pietsch, Ginette Teske, Roland Richter, Cordula Müller, Gabi Spiegel Printing: Universal Medien GmbH, Munich

This work is protected by copyright. The rights founded by this, particularly those of translation, reprinting, lecturing, extraction of illustrations and tables, broadcasting, micro- filming or reproduction by other means and storing in a retrieval system, remain reserved, even for exploitation only of excerpts. Reproduction of this work or of part of this work, also in individual cases, is only permissible within the limits of the legal provisions of the copyright law of the Federal Republic of Germany from 9 September 1965 in the currently valid revision. There is a fundamental duty to pay for this. Infringements are subject to the penal provisions of the copyright law.

The repeating of commonly used names, trade names, goods descriptions etc. in this work does not permit, even without specific mention, the assumption that such names are to be considered free under the terms of the law concerning goods descriptions and trade mark protection and can thus be used by anyone.

Should reference be made in this work, directly or indirectly, to laws, regulations or guide- lines, e.g. DIN, VDI, VDE, VGB, or these are quoted from, then the publisher cannot ac- cept any guarantee for correctness, completeness or currency. It is recommended to refer to the complete regulations or guidelines in their currently valid versions if required for ones own work.