Country Reports

Waste-to-Energy in China: Status and Prospects

Yanlong Li, Wenchao Teng, Weiyun Wang, Tianhua Yang and Rundong Li

1. Introduction ...99

2. Waste management in China ...100

3. Energy recovery or resource recycling? ...102

4. Status of WTE in China ...102

5. Integrated WTE by sources separation in Shenyang ...103

6. Conclusion ...105

7. References ...105 Innovative strategies are needed to deal with the municipal solid wastes which we produce today to achieve the Waste-to-Energy (WTE). The objective of the article is to introduce the status and prospects of WTE in China. WTE meets the requirement of renewable energy and circular. The management of MSW plays an important role.

System boundaries included collection and separation of municipal solid waste and its treatment and disposal by landfilling, composting and incineration. An effective waste focuses on recycling and separating the collection. Source separation can contribute a lot for integrated WTE and environment protection. Advance technology for WTE can reduce emission control. The WTE plants are introduced and evaluated by the net energy efficiency of waste to energy.

1. Introduction

Solid wastes are all the wastes arising from human and animal activities that are nor- mally discarded as useless or unwanted. Because of their intrinsic properties, discar- ded waste materials are often reusable and may be considered a resource for energy recovery. Innovative strategies are needed to deal with the waste we produce today to prevent it from causing problems for future generations. Solid waste management is an increasingly pressing matter in many developing Asian countries especially in China due to the growing volume of the waste and the associated negative impacts on the environment. At present, MSW generation in Asia surpasses 1 million tonnes/day [1].

It is estimated that in 2025, this figure will increase to 1.8 million tonnes/day [1, 3].

This poses a challenge to governments, the public and environment [2]. It is also re- ported that the amount of waste generated strongly reflects the economic status of the

Country Reports

people [5]. Waste composition is also observed to be influenced by economy in the following way; recyclables are more in developed countries of the regions because of the market value of these products.

2. Waste management in China

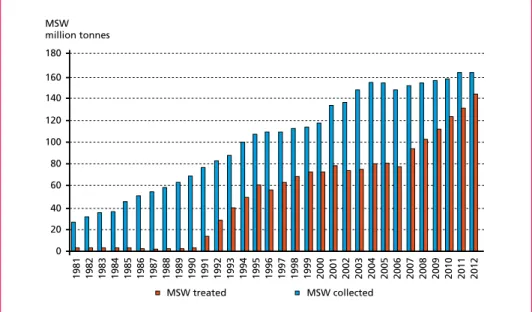

China is a developing country. Development, growth and consumption of goods and services are on the increase in the region. The results of these factors are the increased rate of municipal solid waste generation. The principles of collection and management of this waste are based on the implementation of reduction, reuse and recycling technologies [4, 5]. As shown in Figure 1, MSW generation in China surpasses 160 million tonnes/year, and it is estimated that in 2025, this figure will increase to 200 million tonnes/year. As shown in Figure 1 worrying trends in mu- nicipal solid waste generation in China. As shown in Table 1, the need for MSW management therefore has become paramount. A MSW management includes those measures aimed at reducing the wastes and their adverse effects on the environ- ment [8]. In order to compare and define the advantages and disadvantages of the strategies used on municipal solid waste management systems, various municipal waste management strategies have been investigated. As can be seen in Table 1, there are three main methods to reduce the volume of the municipal solid waste.

80 percent of MSW treatment is landfill, it is a comparatively simple and econo- mic way for municipal solid waste disposal. Moreover, landfilling is the ultimate disposal method waste that cannot be recovered. However, the most problem is that there is no enough room for landfill. With the development of technologies, incineration becomes more popular in China. The capacity of MSW treatment plant for incineration is about 446 thousand tonnes/day. The incineration processing of MSW, used both for volume reduction and energy recovery, is an important element in many integrated waste management systems. It is estimated that MSW incineration will account for approximately 35 percent of waste elimination by the end of 2015 [6]. The main raw material of composting in China is a mixture of living garbage and excrement and a mixture of urban garbage and sewage sludge.

Environmental conditions of temperature and pH have an important effect on the survival and growth of microorganisms for composting. In general, optimal growth occurs within a fairly narrow range of temperature and pH values, although the microorganism may be able to survive with much broader limits. For instance, temperatures below the optimum typically have a more significant effect on the bacterial growth rate than temperatures above the optimum. Moisture content is another essential environmental requirement for growth of microorganisms. In many composting operations, it has been necessary to add water to obtain optimum bacterial activity. However, there are a lot of challenges of MSW management in China. Mixed waste collection and treatment cause unsustainable for landfill, the low calorific value is not suitable for incineration, the low porosity and low quality is not suitable for composting.

Country Reports

Figure 1: MSW collected and treated in China 1981 to 2012

180 160

120 100 80 60

20 0

1981 1982 1983 1984 1985 1986 1987 1988 1989 1990 1991 1992 1993 1994 1995 1996 1997 1998 1999 2000 2001 2002 2003 2004 2005 2006 2007 2008 2009 2010 2011 2012

40 140

MSW collected MSW treated

MSW million tonnes

Figure 2: Hierarchy of waste management: resource recycling and energy recovery

Table 1: Three main modes for MSW treatment

Number of MSW disposal facilities Capacity of MSW treatment plant Year

No. % Capacity %

Landfill Composting Incineration 104 ton/d Landfill Composting Incineration

2004 559 79.43 10.91 9.66 23.85 86.32 6.43 7.09

2008 509 79.96 2.75 15.54 31.52 80.36 1.71 16.37

2009 567 78.84 4.76 16.40 35.56 76.83 3.15 20.02

2010 628 79.30 1.75 16.56 38.8 74.74 1.41 21.88

2011 677 80.80 ND 16.10 40.9 73.40 ND 23.01

2012 701 77.03 ND 19.69 44.6 69.71 ND 27.49

Waste Avoidance Reuse Material-recycling

Energy recovery and treatment Disposal (10 %)

Still in move (packaging deposits, Eco design) by manufacturers (CP) by consumers

Thermal treatment with heat recovery Thermal treatment without heat recovery landfill

Country Reports

3. Energy recovery or resource recycling?

Recycling, energy recovery or resource recycling, is necessary, but China is facing several obstacles: the improvement of public awareness, the limitations of traditional garbage classification, the lack of laws and regulations, and the garbage of recycling facilities is not complete [6]. So it is urgent to develop a new waste management for resources recycling and energy recovery. Waste management may be defined as the discipline associated with the control of generation, storage, collection, transfer and transport, processing, and disposal of solid wastes in a manner that is in accord with the best principles of public health, economics, engineering, conservation and other environmental considerations. The problems associated with the management of solid wastes in today’s society are complex because of the quantity and diverse nature of the wastes. As a consequence, if waste management is to be accomplished in an efficient and orderly manner, the fundamental aspects and relationships involved must be identified, adjusted for uniformity of data, and understood clearly. Figure 2 is the hierarchy of waste management about resource recycling and energy recovery we made. In the hierarchy, the activities associated with the management of wastes from the point generation to final disposal have been grouped into four functional elements: (1) waste generation, separation, storage, collection and reuse; (2) material-recycling; (3) energy recovery and treatment including thermal treatment with heat recovery and thermal treatment without heat recovery; (4) disposal. Energy recovery or resource recycling, it is up to the priority of efficiency. Based on the paper as an example:

Resource recycling:

Cumulative energy demand of Raw materials 35 MJ/kg Energy consumption of resource recovery 15 MJ/kg Energy profit of resource recovery 20 MJ/kg Energy recovery:

The calorific value of paper 13.2 MJ/kg The energy recovery efficiency of WTE 21 to 76 percent Energy profit of energy conversion 5.94 MJ/kg

4. Status of WTE in China

WTE can achieve the targets of circular economy, renewable energy, pollution control, land saving and climate protection. Mixed MSW to Energy: Heating to Power from mixed waste incineration and LFG Utilization from landfill. LFG recovery rate in wes- tern countries ≤ 60 percent, but in China LFG recovery rate ≤ 30 percent.

Waste incineration process includes dry stage, pyrolysis and gasification stage, combus- tion stage, cooling stage and secondary combustor. Main type of incineration includes grate furnace (60 percent), CFB furnace (30 percent), pyro-incineration (5 percent) and

Country Reports

other type (5 percent). Though calculate by ICEEE, 36 million tons MSW incineration amount in China (2012) equals to 3.72 billion m3 of natural gas or 3.54 billion liters oil and it can reduce 14.5 million tons CO2 at the same time.

5. Integrated WTE by sources separation in Shenyang

Fines < 10 mm 4.1 % Others 1.6 % Minerals 0.6 % Complex prod. 1.5 % Hazardous waste 1.4 % Metal 0.3 % Textiles 0.9 % Glass 1.5 % Plastics 6.8 % Paper 6.5 % Wood/Bamboo 1.0 % BMW 73.7 %

Figure 3:

Average composition of MSW in Shenyang (2005 to 2015)

MSW in Shenyang Mass distribution Energy distribution

MSW 100 % m/m FM

100 % Energy

BMW (74 % m/m FM)

RMW ( 26 %)

BMW ( 37 %)

RMW (63 % E)

Figure 4:

Mass and energy distribution of MSW in Shenyang (2005 to 2015)

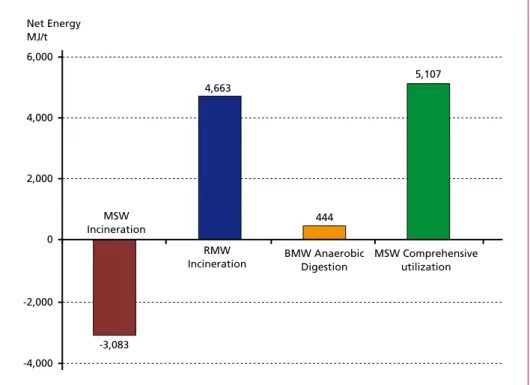

Because of the city scale, living condition and income, the average bio-waste con- tent of MSW is above 66 percent, which is the average of 38 analysis form 27 cities in China. In Shenyang, a central city in northeast of China, this value is 73.7 per- cent, which is shown in Figure 3 and Figure 4. So China cannot copy the model of source separation from developed countries. From Figure 5 and Figure 6, it could be found that: The best way for WTE is to separate bio-waste (BMW) and residual solid waste (RMW). Bio-waste can be used for BMW Anaerobic Digestion to collect energy. The net energy of BMW Anaerobic Digestion can reach up to 433.88 MJ/t.

Country Reports

RMW can be directly used for incineration plant, the net energy of RMW incineration is 4,663 MJ/t, while the net energy of MSW incineration is only -3,083 MJ/t. The CO2 emission reduction of integrated WTE is also greater than MSW incineration and landfill gas utilization.

RMW

Incineration BMW Anaerobic Digestion

MSW Comprehensive utilization -2,000

6,000

4,000

2,000

-4,000 Net Energy MJ/t

MSW Incineration 0

-3,083

4,663

444

5,107

Figure 5: Integrated energy efficiency analysis of some WTE methods

2006 2007 2008

1,000,000

800,000

600,000

400,000

200,000 CO2-Reduction

2005

LFG Utilization

2009 0

2010 2011 2012

years

Incineration Integrated management

Figure 6: Integrated environment efficiency analysis of some WTE methods

Country Reports

6. Conclusion

This review demonstrates that it is fully possible for WTE in China. WTE meets the requirement of renewable energy and circular. The management of MSW can play an important role in WTE. An effective waste focuses on recycling and separating the collection. Source separation can contribute a lot for integrated WTE and environment protection. The WTE plants collect electrical and thermal from solid waste. Advance technology for WTE can reduce emission control.

7. References

[1] Hoornweg, D.; Bhada-Tata, P. (2012): What a Waste: A Global Review of Solid WasteManage- ment. Urban Development & Local Government Unit, World Bank, 1818H Street, NW, Wa- shington, DC 20433 USA

[2] Ngoc, Uyen Nguyen; Schnitzer, H. (2009): Sustainable solutions for solid waste management in Southeast Asian countries. Waste Management 29, 1982-1995

[3] Norbu, T.; Visvanathan, C.; Basnayake, B. (2005): Pretreatment of municipal solid waste prior to landflling. Waste Management 25, 997-1003

[4] Seadon, J. K. (2010): Sustainable waste management systems. Journal of Cleaner Production 18, 1639-1651

[5] Shekdar, Ashok V. (2009): Sustainable solid waste management: an integrated approach for Asian countries. Waste Management 29, 1438-1448

[6] Wu, YC; Xu, LF. (2013): Analysis of the barrier factors of municipal solid waste classification recycling. Adv Mater Res;726–731:2618–21

[7] Wu, E.; Kan, B. (2012): China waste treatment sector. Asia Pacific EquityResearch- JPMorgan;

p. 1–32

[8] Zurbrugg, Ch. (2003): Solid Waste Management in Developing Countries. SANDEC/ EAWAG

TK Verlag Karl Thomé-Kozmiensky

Dorfstraße 51

D-16816 Nietwerder-Neuruppin

Tel. +49.3391-45.45-0 • Fax +49.3391-45.45-10 E-Mail: tkverlag@vivis.de

Waste Management

Waste Management, Volume 1 • Waste Management, Volume 2 • CD Waste Management, Volume 2 Waste Management, Volume 3 • CD Waste Management, Volume 3 • Waste Management, Volume 4

160.00 EUR

save 111.00 EUR

Package Price

Waste Management, Volume 1 Publisher: Karl J. Thomé-Kozmiensky,

Luciano Pelloni ISBN: 978-3-935317-48-1 Published: 2010 Hardcover: 623 pages Language: English, Polish and German Price: 21.00 EUR

Waste Management, Volume 2 Publisher: Karl J. Thomé-Kozmiensky,

Luciano Pelloni ISBN: 978-3-935317-69-6 Published: 2011 Hardcover: 866 pages,

numerous coloured images Language: English

Price: 50.00 EUR CD Waste Management, Volume 2 Language: English, Polish

and German

ISBN: 978-3-935317-70-2 Price: 50.00 EUR

Waste Management, Volume 3 Publisher: Karl J. Thomé-Kozmiensky,

Stephanie Thiel ISBN: 978-3-935317-83-2 Published: 2012 Hardcover: 744 pages,

numerous coloured images Language: English

Price: 50.00 EUR CD Waste Management, Volume 3 Language: English

ISBN: 978-3-935317-84-9 Price: 50.00 EUR

Waste Management, Volume 4 Publisher: Karl J. Thomé-Kozmiensky,

Stephanie Thiel ISBN: 978-3-944310-15-2 Published: 2014 Hardcover: 521 pages,

numerous coloured images Language: English

Price: 50.00 EUR

Order your book on www. .de

or

Karl J. Thomé-Kozmiensky

WASTE MANAGEMENT

Luciano Pelloni

Thomé-Kozmiensky und PelloniWASTE MANAGEMENT

Volume 1 Eastern European Countries Karl J. Thomé-Kozmiensky

Volume 2

WASTE MANAGEMENT

Luciano Pelloni

Waste Management Recycling Composting Fermentation Mechanical-Biological Treatment Energy Recovery from Waste Sewage Sludge Treatment

Thomé-Kozmiensky und PelloniWASTE MANAGEMENT

2

Thomé-Kozmiensky und Pelloni

Karl J. Thomé-Kozmiensky

Volume 3 Recycling and Recovery

WASTE MANAGEMENT

Stephanie Thiel

WASTE MANAGEMENTThomé-Kozmiensky und Thiel

3

2

1

WASTE MANAGEMENT Volume 3

KARL J. THOMÉ-KOZMIENSKY STEPHANIE THIEL HRSG.

Copyright © 2011 TK Verlag Karl Thomé-KozmienskyAlle Rechte vorbehalten.

Das Einspeisen der Daten in Netzwerke ist untersagt.

, Thiel WASTE MANAGEMENT

Volume 3

KARL J. THOMÉ-KOZMIENSKY STEPHANIE THIEL HRSG.

Copyright © 2012 TK Verlag Karl Thomé-Kozmiensky Alle Rechte vorbehalten.

Das Einspeisen der Daten in Netzwerke ist untersagt.

Bibliografische Information der Deutschen Nationalbibliothek Die Deutsche Nationalbibliothek verzeichnet diese Publikation in der Deutschen Nationalbibliografie; detaillierte bibliografische Daten sind im Internet über http://dnb.dnb.de abrufbar

Thomé-Kozmiensky, K. J.; Thiel, S. (Eds.): Waste Management, Volume 5 – Waste-to-Energy –

ISBN 978-3-944310-22-0 TK Verlag Karl Thomé-Kozmiensky

Copyright: Professor Dr.-Ing. habil. Dr. h. c. Karl J. Thomé-Kozmiensky All rights reserved

Publisher: TK Verlag Karl Thomé-Kozmiensky • Neuruppin 2015

Editorial office: Professor Dr.-Ing. habil. Dr. h. c. Karl J. Thomé-Kozmiensky, Dr.-Ing. Stephanie Thiel, M. Sc. Elisabeth Thomé-Kozmiensky.

Layout: Sandra Peters, Ginette Teske, Janin Burbott-Seidel, Claudia Naumann-Deppe Printing: Universal Medien GmbH, Munich

This work is protected by copyright. The rights founded by this, particularly those of translation, reprinting, lecturing, extraction of illustrations and tables, broadcasting, micro- filming or reproduction by other means and storing in a retrieval system, remain reserved, even for exploitation only of excerpts. Reproduction of this work or of part of this work, also in individual cases, is only permissible within the limits of the legal provisions of the copyright law of the Federal Republic of Germany from 9 September 1965 in the currently valid revision. There is a fundamental duty to pay for this. Infringements are subject to the penal provisions of the copyright law.

The repeating of commonly used names, trade names, goods descriptions etc. in this work does not permit, even without specific mention, the assumption that such names are to be considered free under the terms of the law concerning goods descriptions and trade mark protection and can thus be used by anyone.

Should reference be made in this work, directly or indirectly, to laws, regulations or guide- lines, e.g. DIN, VDI, VDE, VGB, or these are quoted from, then the publisher cannot ac- cept any guarantee for correctness, completeness or currency. It is recommended to refer to the complete regulations or guidelines in their currently valid versions if required for ones own work.