Sewage Sludge

Up-to-Date Approach for Thermal and Material Treatment of Sludge

Vladimir Ucekaj, Veronika Kerberova, Jan Krispin and Petr Stehlik

1. Sewage sludge treatment in the Czech Republic ...469

1.1. Legislation in the Czech Republic ...470

1.2. Legislation in Europe ...471

1.3. Composition of sewage sludge ...472

2. Energy and material utilization of sewage sludge ...472

2.1. Waste to energy utilization ...472

2.1.1. Drying ...472

2.1.2. Incineration ...473

2.2. Material utilization ...473

2.2.1. Recovery of phosphorus from stabilized sludge and sludge water ...474

2.2.2. Recovery of phosphorus from sewage sludge ash ...474

3. Proposed technology (Nikita) ...476

4. Conclusion ...478

5. Sources ...479

1. Sewage sludge treatment in the Czech Republic

The sewage sludge is produced as a by-product of sewage treatment and is thus an un- avoidable waste. The quantity can be influenced by wastewater treatment technology or its treatment method. Although sludge accounts for only 1 to 2 % of the total treated wastewater, they contain 50 to 80 % of the original pollution. Sludge treatment costs of up to 50 % of the Waste Water Treatment Plant (WWTP) operating costs. Sewage sludge is a heterogeneous material that contains significant nutrients such as phospho- rus, nitrogen, potassium, calcium and magnesium, but in addition to these beneficial elements, there are many contaminants and pathogenic microorganisms in the sludge.

According to the European Union‘s waste management objectives, recycling is preferable to simple disposal of waste products. This is still achieved (in some EU countries) by direct application to agricultural land or by composting. This practice is leading to a less sustainable way to use sludge due to the content of harmful substances. Also, the landfill of sewage sludge is allowed in the Czech Republic in some cases. Landfilling should be avoided by changing legislation.

Sewage Sludge

In 2017, according to the Czech Statistical Office, there were 2,612 wastewater treat- ment plants in the Czech Republic, while the number is rising each year slightly. The production of sewage sludge since 2010 and the ways of its processing are summarized in Figure 1.

0 20,000 40,000 60,000 80,000 100,000 120,000 140,000 160,000 180,000 200,000

2010 2011 2012 2013 2014 2015 2016 2017

Sludge production tdm

Direct application Composting Landfilling Incineration Other method

Figure 1: Sewage sludge treatment in the Czech Republic

Source: Statistical Yearbook of the Czech Republic - 2018: Sludge production in WWTP and method of their disposal. In: Czech Statistical Office. 2018.

Sludge production in recent years is essentially constant (only a slight increase is ob- served). Direct application of sludge to agricultural land and composting are growing in the reference period.

1.1. Legislation in the Czech Republic

The stabilized, or partially or fully sanitized and dewatered sludge, is treated according to Act No. 85/2001 Coll., on waste. Landfilling of sewage sludge has been banned in the Czech Republic since 2005 by Decree No. 294/2005 Coll [8]. However, the rules of prohibition and exceptions are not clearly defined. It remains unclear how the ban on landfill sewage sludge should be applied, and the landfill can be allowed by the admin- istration in some cases. The final ban is due to the implementation of EU legislation in the national legislation. These include the reduction of landfilled waste (EU landfill is to be banned according to EU requirements from 2035) and reach recycling limits (55 % by 2025 and 60 % by 2030 for municipal waste). In the current situation, there is a debate about shifting the landfill ban from 2024 to 2030, which is justified by the lack of preparedness of the undertakings concerned.

Sewage Sludge

Use of sewage sludge in agriculture undoubtedly has its positives, because nutrients are directly used (especially N and P). On the other hand, sewage sludge presents health and environmental risks due to the content of inorganic contaminants (toxic metals), but also pathogens and organic contaminants (persistent organic pollutants comprising residues of drugs, hormones, etc.). The threat lies in the possible emergence of bacterial resistance. The logical action is to regulate the use of such options. The Czech Republic achieves it by Decree No. 437/2016 Coll., On the conditions of use of treated sludge on agricultural land [7]. This decree set new control mechanisms for assessing the quality and safety of sludge (the obligation to verify the effectiveness of sanitation) and tightened the microbiological criteria. The limits set out in this Decree must be respected from 2020. However, in this case too, a shift in the deadline is being discussed. At the same time, the amendment to Decree No. 474/2000 Coll., On the determination of requirements for fertilizers, tightened the rules for fertilizers, soil conditioners, auxiliary plant preparations and substrates for which waste from waste- water treatment plants was used.

1.2. Legislation in Europe

The Waste Act implements the requirements of the European Union pursuant to Directive 2008/98/EC of the European Parliament and the Council. The goal of waste management is to support the technology of sewage sludge utilization through several measures. Monitoring and evaluation of the amount of sludge produced are considered to be fundamental measures, similar to quality control through microbiological and chemical parameters. The contaminants mentioned above are difficult to control, and the methods for their determination are still developing. As it is well known that the contaminants are present in the sludge, the precautionary principle of sludge use is being applied in EU countries.

In the EU countries, the fundamental document governing the treatment of sewage sludge is Council Directive 86/278/EEC [6]. However, like all other directives, it only gives a basic framework for sludge management, while countries can regulate sludge treatment. The current regulatory framework is highly heterogeneous in EU countries.

The EU countries have to respect the European Parliament and Council Regulation 2003/2003 on fertilizers and also the national rules of the countries concerned if sew- age sludge is used as fertilizer. The Regulation does not impose any nutrient limits or maximum levels of contamination in fertilizer products. The unified rules for the supply of fertilising products to the market and the promotion of the reduction of Europe‘s de- pendence on the import of phosphorous products are brought by the proposal for a new Regulation of the European Parliament and of the Council (Ref.: 2016/0084 (COD)).

The Regulation introduces the so-called CE system in the field of fertilizer products.

The new Regulation introduces acceptable levels of minimum and maximum nutrient concentrations into the fertilizer product range as well as the maximum permissible concentration of contaminants in individual types of CE marked fertilizer products.

At the same time, it introduces quality requirements for input materials from which CE marked products can be made [21].

Sewage Sludge

1.3. Composition of sewage sludge

The aim of the project of the Technology Agency of the Czech Republic is to map the sewage sludge as a secondary source of phosphorus in the Czech Republic by the as- sessment of the amount and form of phosphorus and the risk elements. Sludge samples were taken from selected WWTPs according to their size (population equivalent), tech- nology and location. Within the project, the elemental composition of sludge and basic fuel-energy properties of sludge were monitored. The average amount of phosphorus is 20 g/kgdm. Based on simplified calculations, it can be concluded that at least 18 % of the fertilizers can be replaced by sewage sludge. In this assessment it is important to assess the content of heavy metals – the legislative limits were most often exceeded in the case of As, Cd, Ni and Pb. The highest recovery of phosphorus is the use of ash after incineration. Ash content ranges from 45,3 to 49,9 %, the combustible content is from 48,9 to 54,6 %. The calorific value ranges from 8,9 to 13,1 MJ/kgdm.

2. Energy and material utilization of sewage sludge

With the further development of society, sludge production in the world is expected to grow. However, these facts do not mean that the acceptable disposal of sewage sludge is impossible. On the contrary, there is rapid progress and relatively new sustainable practices. Following the objectives of waste management, it is possible to use the organic sludge component as a source of energy and materials.

2.1. Waste to energy utilization

Although raw sewage sludge is not the best fuel for heating purposes, it does contain combustible components, making it possible to use for energy utilization. As not- ed above, many treatment plants are faced with legislation requirements, which in practice means to perform at least sanitation. In most cases, this is done by thermal process or by adding lime. Both techniques are quite problematic. Thermal treatment is energy-intensive due to the high water content in the sludge. Adding lime is user unfriendly process due to its dustiness. A possible way to deal with this problem is to burn the organic content in the sludge, using its energy, instead of applying external heat for conducting the process.

2.1.1. Drying

Raw sewage sludge has a few negatively physical properties. For instance, some of them are stickiness, high viscosity, sintering tendency and low flame temperature. These prop- erties limit the application of many combustion technologies. However, their application can be enabled by pre-treatment of the raw sludge. The pre-treatment is done in several steps. First, raw sludge needs to be prepared into a specified shape and dimension state.

This allows to better maintain steady-state of the combustion process and design the process more accurately. Defined particles are then distributed within the dryer and dried. This can be done by both low-temperature and high-temperature drying.

Sewage Sludge

Low-temperature drying is safer due to the large difference between the drying me- dium temperature and the ignition point of the sludge. However, due to the smaller total temperature difference, a higher flow rate of the drying medium is needed. Better energy efficiency can be achieved by heat recovery but still, we the significant moisture content has to be removed from the sludge. It is also necessary to consider the drying medium. Common medium used is air heated up by natural gas combustion. However, this would make impossible the utilization of the sludge energy content. Here comes energy utilization – one could make use of hot utility (water, steam etc.) from flue gas, or can use directly flue gas diluted with air.

Although high-temperature drying poses some risks, it allows much lower dilution of the flue gas by air. In this way, the emissions are in favourable concentrations for flue gas cleaning. The drying medium volume flow rate is smaller. This opens some serious questions about the possible combination of feasible dryers which are durable enough to withstand higher temperature and aggressive chemical environment.

2.1.2. Incineration As commented before, there are conventional technologies, which can process raw sewage sludge. However, in terms of waste incineration legislation, this means we have a large heat surplus at the output, which may not be needed. From this point of view, conventional technologies cannot sustain as many WWTP that do not pose heat demands.

There are several boundary conditions. One of them, which is limiting and is required by legislation, is to sustain at least two seconds over 850 °C. For raw sludge, this condi- tion is problematic due to its low incineration temperature as a result of its low Lower Heating Value (LHV). However, if the sludge is dried before the incineration, the flame temperature can reach the required temperature without difficulty.

Another problem is sludge sintering. When reaching high temperatures, sintering occurs, and it could lead to a higher level of organic content in the ash. The same problem can occur due to temperature shocks. In this context, the frequent crushing of combusted particles could help.

Diffusivity is another physical phenomenon which influences the process. Large par- ticles are combusting slower and release heat at lower rates, which limits the flame temperature.

These conditions set the boundaries for feasible combustion technologies. There is a need for complying with the legislation, temperature level – not too high and not too low and also to deal with particle sintering. Altogether, connection of drying and combustion processes can lead to higher efficiency, lower investment and process simplification. One such possibility is discussed further.

2.2. Material utilization

A WWTP has to remove the phosphorus from the treated water to the specified lim- its. By removing the phosphorus from the wastewater, most of it gets into the sludge.

Sewage Sludge

Therefore, sewage sludge is an important secondary source of phosphorus, from which it is possible to recycle phosphorus by several technological processes depending on the matrix (most significant is anaerobic digestion sludge, sludge water, ash).

The majority of primary research on phosphorus extraction from secondary sources began in 2007/2008. The price of phosphorus has risen rapidly in this period to nine times the original value caused by a relatively sudden limitation of some countries‘

phosphate ore exports due to serious depletion concerns in the near future. Also, the consumption of phosphate products in the EU continues tends to grow [15]. The EU is dependent on this commodity. Therefore, phosphorus has been listed as a critical raw material since 2014. This situation underlines the importance of introducing innova- tive technologies to support and enable the use of secondary raw materials. Currently, a number of methods are developed only on a laboratory scale, mainly for economic reasons [12]. It is expected that, in the next 20 years, phosphorus extraction technol- ogies will be used increasingly, especially with regard to the forthcoming but already approved legislative conditions. About 50 different methods have been laboratory tested for phosphorus recycling over the past decade – from simple precipitation of dissolved P to more complex multi-stage processes.

2.2.1. Recovery of phosphorus from stabilized sludge and sludge water

Methods that utilize anaerobic sludge or sludge water as the source of phosphorus have arisen secondarily as a consequence of avoiding operational problems caused by encrustation (precipitation of phosphorus) in the pipeline. The advantage of these methods is the improvement of the drainage capacity of the sludge and thus reduce the operating costs of further processing. On the contrary, the disadvantage is the high water content, which requires more processing capacity. The methods are based on wet oxidation, supercritical water oxidation, or metallurgical melting. The removal of interfering substances is accomplished by precipitation, leaching or ultra- or na- no-membranes. The resulting product after precipitation or filtration is phosphorus in the form of CaP or struvite. Both these forms can be used as fertilizer after purification.

The disadvantage of these methods is the low recovery rate – it is only 10 to 25 % with respect to the wastewater inflow (which is not decisive with respect to the primary purpose of the method).

2.2.2. Recovery of phosphorus from sewage sludge ash

The advantage of sludge thermal treatment is the capture of more than 90 % of phospho- rus in the sewage sludge ash, which represents about 20 to 30 % wt. – which is similar to commercial fertilizers. On the other hand, heavy metals exhibit similar behaviour and complicate subsequent use of sewage sludge ash.

An overview of methods for recycling phosphorus from ash is given in Figure 2. Com- pared to the methods, described above, there is a considerable difference in the application of industrial-scale methods, which is mainly due to the smaller spread of combustion methods for the final sludge treatment and hence less processing options for ash.

Sewage Sludge Figure 2: Phosphorus recovery from sewage sludge ash

Source: Kabbe, Ch.; Remy, Ch.: Sustainable sewage sludge management fostering phosphorus recovery in Europe, In: P-REX - Phosphorus recycling, Germany, 2013.

Phosphorus is present in sewage sludge ash in the form of almost insoluble aluminium and iron phosphates. The most important parameter in assessing the use of phosphorus from ash is its bioavailability. Low bioavailability is shown by phosphorus bound to iron, aluminium or manganese (non-apatite inorganic phosphate, NAIP). In untreated ash after sludge burning, the solubility of phosphorus is only about 25 to 40 %. This is very low compared to conventional fertilizers. The opposite effect has the presence of calcium or magnesium ions (phosphate is in the form of apatite phosphate, AP). In this case, the solubility of phosphorus is up to 80 %, which is comparable to commercial fertilizers and can thus be directly absorbed by plants. The classification of the various forms of phosphorus is shown in Figure 3.

total phosphorus Ptot

organic Porg inorganic

Pin

apatit AP Ca/mg-P non-apatit NAIP

Al/Fe/Mn-P

In addition to the phosphorus form, the presence of toxic metals also affects the final use of residues. The concentration of toxic metals can be reduced, for example, by the addition of chlorides (a method known as AshDec/Outotec) [20]. The principle of the method is to mix the ash with the reagent and keep the mixture at a high temperature for at least 20 minutes. During the process, NAIP is transformed into AP, which positively

Figure 3:

Phosphorus form in sewage sludge ash

Source: Li, R.; Teng, W. et al.: Potential recovery of phosphorus during the fluidized bed incineration of sewage sludge, In:

Journal of Cleaner Production, 2017, 140, pp. 964-970.

Sewage Sludge

affects phosphorus solubility and subsequent plant use. The disadvantage is the low degree removal primarily of Cr and Ni. Increasing the indicated bioavailability values (up to 75 %) provides replacement of chloride ions with sodium sulphate (AshDec Rhenania method). This method is only tested on a laboratory scale.

Other methods include Leachphos [11]. This method is based on chemical leaching and achieves the phosphorus recycling efficiency of up to 80 % (based on the total amount of P per WWTP). Compared to AshDec, it allows removal of Cr, Ni and Fe at low pH, while Cd and Pb are concentrated in the final product. The German company is con- ducting a pilot study to verify the Mephrec method [13]. The industrial scale method in France and Bulgaria is EcoPhos – in this case up to 99 % of phosphorus is obtained in the form of phosphoric acid. Interfering ions are gradually removed by selective ion exchangers, so the toxic metal content is low in the final product. Information regarding the behaviour of toxic metals is not comprehensive, and generalization of methods for recycling phosphorus from ash is therefore not possible. Investigating and testing heavy metal removal options is a very complex process based on the selected sludge pretreatment and treatment technology and their composition [12].

3. Proposed technology (Nikita)

Recent challenges and intense scientific discussion over the past few years have led to the need to find a suitable sludge treatment solution to reduce toxic metal concentra- tions and mobility, increase phosphorus bioavailability, degrade organic pollutants, and hygienise sewage sludge by removing microbiological pathogens. A number of methods have been developed for the final sewage sludge treatment, but only a few of them are technologically and economically feasible. The optimum sewage sludge treatment process should ensure sufficient sanitation, maximum energy and substance utilization while minimizing costs, overall energy consumption and other materials.

These requirements correspond best to the thermal destruction method. In the Czech Republic, there is a problematic interpretation of the legislation and the general public disagreement, which is related to the insufficient market supply of such technology solutions and more distrust of investors. Energy and material sewage sludge utilization methods are currently operated separately in the world, which means higher investment and operating costs. Because the methods of thermal utilization of sewage sludge are not practiced in the Czech Republic, there is an opportunity to take the whole process of modernization of sewage sludge management comprehensively and thus to consid- er an integrated solution of energy and material utilization of the sludge, which will implement the circular economy principles.

The technology is based on the principle of drying and subsequent thermal oxidation (incineration) of sludge dry matter while producing flue gas. The energy content of flue gas (heat) is used for the sludge drying. At the same time, the use of a suitable additive reduces the content of toxic metals in the sludge and increases the bioavailability of phosphorus. The product of this technology is a phosphorus-rich solid residue (ash) with a substantially reduced content of heavy metals and xenobiotics, which can be used directly as phosphate mineral fertilizer. The heavy metals are evaporated and trapped in the flue gas cleaning system.

Sewage Sludge

The treatment process flowsheet (Annex 1) shows the flowsheet of the proposed process.

It consists of the following parts:

• storage and dosage of dewatered sewage sludge,

• drying of dewatered sewage sludge,

• incineration,

• exhaust gas cleaning and

• storage and packing of mineral fertilizer.

The drying technology is represented by a high-temperature rotary dryer with direct contact between the dried sludge and the drying medium – a mixture of ambient air and flue gas from the sludge incineration. Mixing the flue gas with air is necessary to achieve a suitable temperature and moisture content of the drying mixture. An alterna- tive source of heat is a natural gas burner. However, it is not considered for its normal operation. The burner will only be operated at the moment of initiation.

Exhaust gas from the dryer is cleaned in a set of waste gas purification that consists usually of a wet absorption chemisorption scrubber with an acidic and alkaline stage.

Purified vapour flow is released into the atmosphere through the chimney. Part of the vapour is introduced back into the dryer as a recycle. This measure contributes to the efficiency of the incineration process and to the reduction of certain pollutants (ni- trogen oxides). The dryer operates at a drying medium temperature of 120 to 400 °C and operates at sub-atmospheric pressure as well as the entire technology, preventing uncontrolled leakage of flue gas, drying medium and exhaust gas to the environment.

The sewage sludge is completely sanitized in the sense of the Decree. No. 437/2016 Coll [7]. Sewage sludge is microbiologically stable and in terms of fuel efficiency reaches the calorific values guaranteeing autarkic burning at a temperature above 850 °C. Dried sewage sludge is immediately transported into the hopper of the rotary kiln, where it is dosed into the combustion chamber. Due to the rotation and inclination of the furnace, the sludge is inverted and gradually conveyed to the output from the furnace.

The flue gas is introduced into the rotary dryer after mixing with the ambient air in the mixer at the exit of the rotary kiln. The rotary kiln is equipped with a heavy lining and a powerful gas burner. This is used for initiation and stabilization of the incinerat- ing process under non-standard conditions. The solid residue after combustion is led through a cooled screw conveyor via a pressure closure and other conveyors to closed storage containers.

Figure 4: Dried sewage sludge Figure 5: Incinerated sewage sludge (ash)

Sewage Sludge

The technology concept was tested and verified during the semi-operational tests.

The testing unit consisted of a drum dryer and a rotary kiln in the scale of 1:10 (inlet mass flow of dewatered sewage sludge 80 kg/hour). For testing the sludge was treated with the additive to lower the content of toxic metals. Figure 5 and 6 show dried and incinerated sludge (ash).

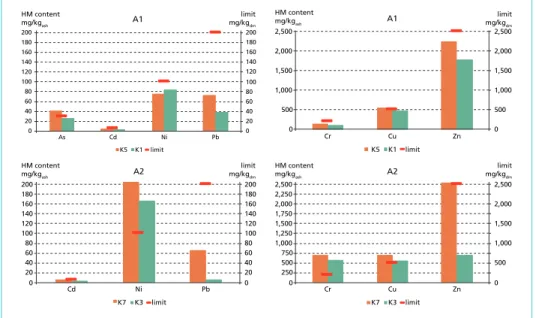

Figure 6 shows the results of the incineration tests. The content of toxic metals was monitored. The WWTP1 A1 compares the toxic metal content of dried (K5) and incinerated sludge (K1). The WWTP2 A2 compares the toxic metal content of dried sludge (K7) and additive-treated and incinerated sludge (K3). As expected, the additive proved good efficiency of Zn and Pb removal whereas almost no efficiency in remo- ving of Cd, Ni, Cr and Cu. The results of the test should be taken as preliminary. The technology parameters have to be further adjusted – mixing of additives with sewage sludge, incineration condition etc.

Figure 6: The result of sewage sludge incineration test

4. Conclusion

Sewage sludge treatment in the Czech Republic has to change substantially due to the legislation requirements on sanitation and phosphorus recycling. The situation in the Czech Republic offers a new possibility of combining the usually separated process of drying, incineration and further ash processing. For this purpose, new technology was designed and this concept was tested on a semi-operational basis, showing promising results.

0 20 40 60 80 100 120 140 160 180 200

0 20 40 60 80 100 120 140 160 180 200

As Cd Ni Pb

limit

mg/kgdm limit

mg/kgdm

limit mg/kgdm limit

mg/kgdm HM content

mg/kgash A1

K5 K1 limit

0 500 1,000 1,500 2,000 2,500

0 500 1,000 1,500 2,000 2,500

Cr Cu Zn

HM content

mg/kgash A1

K5 K1 limit

0 20 40 60 80 100 120 140 160 180 200

0 20 40 60 80 100 120 140 160 180 200

Cd Ni Pb

HM content

mg/kgash A2

K7 K3 limit

0 500 1,000 1,500 2,000 2,500

0 250 500 750 1,000 1,250 1,500 1,750 2,000 2,250 2,500

Cr Cu Zn

HM content

mg/kgash A2

K7 K3 limit

Sewage Sludge

5. Sources

[1] Act 185/2001 Coll., On waste and on amendments to some other acts. In: Ministry of Environ- ment of the Czech Republic, 2017.

[2] Adam, C.; Peplinksi, B. et al.: Thermochemical treatment of sewage sludge ashes for phosphorus recovery, In: Waste Management, 2009, 29(3), pp. 1122-1128.

[3] Amann, A.; Zoboli, O. et al.: Environmental impacts of phosphorus recovery from municipal wastewater, In: Resources, Conservation and Recycling, 2018, 130, pp. 127-139.

[4] Communication from the commission to the european parliament, the council, the european economic and social committee and the committee of the regions On the review of the list of critical raw materials for the EU and the implementation of the Raw Materials Initiative /*

COM/2014/0297 final */, 2014.

[5] Cordel, D.; Rosemarin, A.; Schröder, J.; Smit, A.: Towards global phosphorus security: A systems framework for phosphorus recovery and reuse options. In: Chemosphere, 2011, 84(6), pp. 747- 758.

[6] Council Directive of 12 June 1986 on the protection of the environment, and in particular of the soil when sewage sludge is used in agriculture (86/278/EEC), In: European Union, 2018.

[7] Decree No. 437/2016 Coll., On the use of treated sludge on agricultural land. In: Ministry of Environment of the Czech Republic, 2016.

[8] Decree No. 294/2005 Coll., The conditions for depositing waste in landfills and their use on the ground surface. In: Ministry of Environment of the Czech Republic, 2005.

[9] Dohányos, M.: Efficient use and disposal of sewage sludge. In: CZ Biom online. 2001.

[10] Donatello, S.; Cheeseman Ch.:Recycling and recovery routes for incinerated sewage sludge ash (ISSA): A review, In: Waste Management, 2013, 33(11), pp. 2328-2340.

[11] Egle, L.; Rechberger H.; Krampe, J.; Zessner, M.: Phosphorus recovery from municipal waste- water: An integrated comparative technological, environmental and economic assessment of P recovery technologies, In: Science of The Total Environment, 2016, 571, pp. 522-542.

[12] Egle, L.; Rechberger H.; Zessner, M.: Overview and description of technologies for recovering phosphorusfrom municipal wastewater. In: Resources, Conservation and Recycling, 2015, 105, pp. 325-246.

[13] Grüner, G. et al: Phosphorus recycling by Mephrec – State of development, 2015.

[14] Herzel, H.; Krüger, H.; Hermann, L.; Adam, Ch.: Sewage sludge ash — A promising secondary phosphorus source for fertilizer production, In: Science of The Total Environment. 2016, pp.

542, 1136-1143.

[15] Historical Phosphate Rock Prices and Price Chart, In: InfoMine [online], 2018.

[16] Kabbe, Ch.; Remy, Ch.: Sustainable sewage sludge management fostering phosphorus recovery in Europe, In: P-REX - Phosphorus recycling, Germany, 2013.

[17] Kos, M.: Current views on sludge utilization, In: Industrial Ecology [online], Czech Republic, 2019.

[18] Li, J.; Tsang, D.: Fate of metals before and after chemical extraction of incinerated sewage sludge ash. In: Chemosphere, 2017, 186, pp. 350-359.

[19] Li, R.; Teng, W. et al.: Potential recovery of phosphorus during the fluidized bed incineration of sewage sludge, In: Journal of Cleaner Production, 2017, 140, pp. 964-970.

[20] Hermann, L.: Outotec modular energy and phosphorus recovery processes, In: Phosphorus platform EU, 2015.

Sewage Sludge

[21] Proposal for a Regulation of the European Parliament and of the Council laying down rules on the making available on the market of CE marked fertilising products and amending Regulations (EC) No 1069/2009 and (EC) No 1107/ 2009; No. COM/2016/0157 final-2016/084, In: Brusel:

European Commission, 2016.

[22] Statistical Yearbook of the Czech Republic - 2018: Sludge production in WWTP and method of their disposal. In: Czech Statistical Office. 2018.

[23] Success stories in nutrient recycling and stewardship, In: European Suistanable Phosphorus Platform [online].

[24] Udayanga, Ch.; Veksha, A et al.: Fate and distribution of heavy metals during thermal processing of sewage sludge, In: Fuel. 2018, 226, pp. 721-744.

[25] Václavková, Š.; Šyc, M.; Moško, J.; Pohořelý, M.; Svoboda, K.: Fertilizer and Soil Solubility of Secondary P Sources—The Estimation of Their Applicability to Agricultural Soils. In: Environ Sci Technol, 2018, 52(17), pp. 9810-9817.

[26] Waste Source Conference Proceedings. Institute of Circular Economics, Choťovice, 2019.

Contact Person

Ing., Ph.D. Vladimir Ucekaj EVECO Brno, s.r.o.

System technologist Technology department Brezinova 42

616 00 Brno

CZECH REPUBLIC +420 544527231 ucekaj@evecobrno.cz

Bibliografische Information der Deutschen Nationalbibliothek Die Deutsche Nationalbibliothek verzeichnet diese Publikation in der Deutschen Nationalbibliografie; detaillierte bibliografische Daten sind im Internet über http://dnb.dnb.de abrufbar

Thiel, S.; Thomé-Kozmiensky, E.; Winter, F.; Juchelková, D. (Eds.):

Waste Management, Volume 9 – Waste-to-Energy –

ISBN 978-3-944310-48-0 Thomé-Kozmiensky Verlag GmbH

Copyright: Elisabeth Thomé-Kozmiensky, M.Sc., Dr.-Ing. Stephanie Thiel All rights reserved

Publisher: Thomé-Kozmiensky Verlag GmbH • Neuruppin 2019 Editorial office: Dr.-Ing. Stephanie Thiel, Elisabeth Thomé-Kozmiensky, M.Sc.

Layout: Claudia Naumann-Deppe, Janin Burbott-Seidel, Sarah Pietsch, Ginette Teske, Roland Richter, Cordula Müller, Gabi Spiegel Printing: Universal Medien GmbH, Munich

This work is protected by copyright. The rights founded by this, particularly those of translation, reprinting, lecturing, extraction of illustrations and tables, broadcasting, micro- filming or reproduction by other means and storing in a retrieval system, remain reserved, even for exploitation only of excerpts. Reproduction of this work or of part of this work, also in individual cases, is only permissible within the limits of the legal provisions of the copyright law of the Federal Republic of Germany from 9 September 1965 in the currently valid revision. There is a fundamental duty to pay for this. Infringements are subject to the penal provisions of the copyright law.

The repeating of commonly used names, trade names, goods descriptions etc. in this work does not permit, even without specific mention, the assumption that such names are to be considered free under the terms of the law concerning goods descriptions and trade mark protection and can thus be used by anyone.

Should reference be made in this work, directly or indirectly, to laws, regulations or guide- lines, e.g. DIN, VDI, VDE, VGB, or these are quoted from, then the publisher cannot ac- cept any guarantee for correctness, completeness or currency. It is recommended to refer to the complete regulations or guidelines in their currently valid versions if required for ones own work.