213 Online Determination of Elementary and Fractional Waste Composition

Waste Incineration

Online Determination of Elementary and Fractional Waste Composition

for Municipal Solid Waste Incineration Plants (MSWIP)

Tobias Widder, Michael Beckmann and Philip Reynolds 1. Information demand on fractional composition

of heterogeneous input materials ...214

2. Determinateness of waste through classification in representative fractions ...215

3. Mathematical description of the matter by target function and constraints ...216

4. Algorithm independent application of the numerical optimization method ...221

5. Calculation results and validation approaches ...221

6. Online-application potentials ...224

7. Conclusion ...225

8. References ...226 Detailed knowledge about composition and constitution of input materials is indis- pensable for efficient waste incineration processes. At present the determination of the input waste mass flow is done in much most cases by helps of the crane weight delivering the average feed mass flow for a one to four hour time period. Because of the relationship between mass and energy balance the lower heating value of the waste (as a quality feature) is also only a several hour average value. A progress is the online calculation of the instantaneous incinerated waste mass flow and waste lower heating value by the online balancing method [1]. On the basis of this additional information an optimization of the plant operation by the plant stuff is still possible e.g. through a better waste homogenization in the waste bunker by the crane driver. The more data about elemental and fractional waste composition is available; the substantial higher is the plant optimization potential. The fractional composition is not only important from a procedural point of view but likewise from a commercial perspective for the plant owner. In the following article a method is introduced which allows to deter- mine the waste composition derived from predefined waste fractions. On the one hand the time-dependent course of this detailed waste composition can be used for revise

Tobias Widder, Michael Beckmann, Philip Reynolds

214

Waste Incineration

of waste homogenization in the bunker and on the other hand it is moreover very adjuvant to deduce expectable pollutant emissions or its precursors by means of the distinguish elemental composition of waste fractions. In combination with sensors for the detection of for instance boiler deposit formation and boiler deposit characteris- tics existing correlations between waste composition and deposit behaviour become useable. Appropriate approaches, models and methods are published by Reiche et al.

[8] and Mueller et al. [5].

Already existing is an approach to calculate specific waste fractions with help of histo- rical average data of a MSWIP, the Bilanzenmethode, which is described by Rechberger et al. [6, 7] and Schwarzböck et al. [9]. This is a procedure to calculate four subdivided waste material group’s ash content (inert material), biogenic content, fossil content and water content. The aim is to determine the biogenic content. Initial point is the historic measurement-in-use-data which is given averaged to a system of equations for being solved by the least squares method. The system of equations contains five mass balances and one material balance. The centrepiece is an equalization calculus on the overdetermined system of equations.

In contrast to this facts, the following described method is suitable to run almost real- time and has no general restrictions concerning fraction numbers and constraints.

Due to the aspect that the Bilanzenmethode was especially developed to a very concrete case; a transfer to similar structured, but in frame conditions different tasks is difficult.

Therefore a new method is required.

1. Information demand on fractional composition of heterogeneous input materials

Because the instantaneous composition and the instantaneous throughput of the waste are not directly determinable by sensors, well-proven tools for indirect balance- based calculation of elemental waste characteristics can be applied. One of these is the Online-balancing tool that provides, using standard available operating measurement instrumentation and on the basis of energy, mass and material balances incipient on the emission measurement at the chimney and behind the firing:

• the elemental waste components C, H, O, W,

• the heating value,

• an instant of time mass-flow,

related to the input waste fuel. Corresponding to the data connection with the distri- buted control system these balanced values will be calculated as (almost) instantaneous data or historic data. For further details to this already multiple publicized topic see pertinent literature [2, 3].

For numerous processes, especially in the area of flue gas treatment (for example [10]) and the combustion technique, these with the aid of the Online-Balancing tool obtained additional information are very helpful, but still developable. High-grade

215 Online Determination of Elementary and Fractional Waste Composition

Waste Incineration

relevant would be for example the nitrogen and sulphur content in the waste fuel as well as the ash content, that are not quantifiable with common methods. With a view to the questions concerning deposit cleaning in waste incinerator firing the kind of linkage and the mineral compound content are of importance. For generating this data, one performant possibility is to find out the instantaneous fractional composition of the incinerating waste. By means of the assignment of average values for quantifiable elemental properties to singular predefined feasible waste fractions, many parameters and characteristics can be specified for the resulting fraction blend. This approach allows creating an extensive image for the reacting input material. For illustration the following Figure 1 is represented, which shows the composition of the resulting waste built up by the singular waste fractions with their own elemental or further accompa- nied properties:

Fraction A

Fraction B

Fraction Fraction C

Fraction D E Fraction

F Fraction G

Fraction H Fraction

I

η αβ δ γ ε ζ

Figure 1:

Composition of the resulting waste. The fractions A to I are defined waste fractions (see below). The Greek letters match to elemental compounds and may represent further attributes like volatiles content.

2. Determinateness of waste through classification in representative fractions

Waste classification in distinctive waste fractions requires that parameters, which cha- racterize the general waste, are also appropriate to characterize representative waste fractions. Then the calculation of the resulting waste blend is achievable by means of a weighted summation if the particular fraction waste percentages are known. Besides validity of conservation equations for needed parameters is necessary. For example bulk density is a parameter that is assignable for general waste as well as for singular waste fractions basically, but it is not admissible to calculate the bulk density of the general waste by summating bulk densities of the singular waste fractions. This is a fact on the grounds that volume conservation is not valid for solid, bulky waste. A biunique

Tobias Widder, Michael Beckmann, Philip Reynolds

216

Waste Incineration

assignment of quantitative attributes for input materials as well as for its sub-categories allows in general identification in both directions: In case of known waste fractions it is possible to quantify the associated attributes with aid of the stored representative data and otherwise the fraction is defined by quantitative attributes as lower heating value, elemental composition etc. if the number of attributes is high enough. These above mentioned essential relationships are only feasible for mass and energy specific properties because using conservation equations for balancing is preconditioned.

For determination of waste fractions from input materials properties which are obtained by applying the Online-balancing tool biunique assignment or biunique attributable properties implies, that there exists (only) one combination of singular waste fractions which coincides all generated quantified information. The term biunique is concerning the discretization of quantified attributes (the accuracy of all parameters is limited) not to grasp as rigidly mathematical and always connected with the sum (mentioned as combination) of (for example from online-balancing tool) provided data for fraction calculation. For instance, the particular attribute carbon content is not appropriate for a biunique assignment because it is no unique feature of the waste fraction. An exception could be extremely high carbon contents that are caused by mono-fractions with in comparison maximum carbon mass percentage (like carbon fibre laminate).

Altogether a lower limit of characteristic property data is required to create a specific input material/waste profile which is suitable to be correlated with an equivalent frac- tion blend (combination of fractions) despite unavoidable tolerances. The more data can be collected about the respective waste fuel, the higher is the probability to meet a biunique assignment and therefore to attain the goal.

3. Mathematical description of the matter by target function and constraints

From a mathematical point of view an adequate approach to solve the mentioned task is via carrying out an optimization model. For this purpose a target function is ex- pressed which has to be fulfilled with consideration of all constraints. The variables of the target function concurrent constitute desired parameters. The following procedure with correlated mathematical relations builds up the approach to calculate fractional composition:

• Step 1: Definition of singular waste fractions

The following waste fractions were chosen for implementation of the described approach (Figure 1, fractions A to I):

* A/PPK (Fraction name): Cellulose products (Description),

* B/Glass: Glass and ceramics,

* C/Plastics: Carbon hydrides with high heating value,

* D/E-Scrap: Electric devices, gadgets, cables etc.

* E/Wood: Natural finish and treated wood,

217 Online Determination of Elementary and Fractional Waste Composition

Waste Incineration

* F/Composites: Multi component materials (Tetrapak…),

* G/Organics: Kitchen and garden refuse,

* H/Textiles: Synthetic and natural fibre,

* I/Fine fraction: Predominant inert dusty material.

• Step 2: Assignment of fraction attributes for predefined properties (Figure 1, Greek letters )

These in step 1 chosen fractions become correlated with concrete values for

* Carbon content (dry and ash-free, daf),

* Hydrogen content (daf),

* Oxygen content (daf),

* Nitrogen content (daf),

* Sulphur content (daf),

* Chloride content (daf),

* Water content (ash-free, af),

* Ash content (raw),

* Heating value (daf),

* Content of fixed carbon,

* Minimum air requirement,

* … (e.g. Volatiles content),

that describes a representative average value in each category for the respective recharge area (regional/national/continental). Equally to the decision for certain fractions the choice of attributes is not restrictive, but depends on the pursued application and at a lower level on the system sided provided data.

• Step 3: Definition of fraction mass percentage as aspired variable

The numerical optimization calculation is computed for the purpose to determine predefined waste fraction percentages i. For the description of this mass percentage the variable v is introduced.

• Step 4: Mathematical relationship of attributes to characterize the resulting waste On the basis of the initially described conservation equations the relationship between attributes k of singular fractions i and those of resulting waste is set by (with describing weight per cent of input material components and describing weight per cent of an input material sub category component):

Ξk,waste = 9 vi • ξk,i

i = 1 (1)

hu,waste = vi • hu,i

9

i = 1 (2)

Tobias Widder, Michael Beckmann, Philip Reynolds

218

Waste Incineration

• Step 5: Definition of the target function

The target function of the numerical optimization expresses that the sum of all waste fractions have to result in one hundred percent and can be formulated – depending on the optimization method settings – as linear or quadratic equation. This relationship seems to be trivial, but contains on the one hand the correlation with singular fraction attributes and is on the other hand necessary for the formal mathematical structure.

Essential information is considered by means of the constraints.

• Step 6: Definition of constraints (Two types: equality/inequality)

With help of the constraints the pool of potential solutions decreases so far that only an extreme small number (in terms of biuniqueness) is appropriate to satisfy the target function. Indeed it is important to indicate that the constraints must not except each other in a mathematical meaning – for example as consequence measurement system failure – because solutions cannot be computed or are not correct in this case.

In concrete matter the constraints are divided in two categories: equal conditions and inequal conditions. Equal conditions are:

ΞC,waste =ξC,OB ΞO,waste =ξO,OB ΞW,waste =ξW,OB

hU,waste =hU,OB

(3)

As previously mentioned, this constraints specify some attributes as input parameters, which are valid for the particular calculated waste referred to the Online-balancing tool. The computed waste exclusively contains the predefined fractions. All equal and inequal conditions limit the expectable fluctuation range for waste fractions and reduce therefore the solution set to reasonable compositions. Unrealistic fraction mass percen- tages like 70 Ma.-% wood or waste blends containing for instance 50 Ma.-% plastics and 50 Ma.-% glass are avoided in this way. Dependent on the spectrum of the delivered waste this constraints have to be adjusted for each application case individually. Table 1 illustrates the described issue.

Mass percentage Mass percentage Waste fraction lower limit upper limit

Ma.-% Ma.-%

A/PPK 12.4 31.4

B/Glass 1.9 9.0

C/Plastics 8.6 24.0

D/Electronic scrap 0.2 3.4

E/Wood 1.0 18.8

F/Composites 2.0 13.0

G/Organics 23.2 47.9

H/Textiles 4.4 14.8

I/Fine fraction 8.2 15.0 Further range conditions Lower limit [-] Upper limit [-]

C/H-ratio 6.8 8.2

Table 1:

Secondary constraints for nume- rical fraction classification

data by Mast, P.-G.: Einfluss der Abfall- zusammensetzung auf Schadstoffgehalt und -menge der Verbrennungsrückstände [Waste composition influence on conta- minant content and quantity of the waste incineration residues], report, 1998

− IN AN EXCELLENT POSITION TO FACE THE FUTURE.

Converting waste into energy is a practice that’s growing in popularity. It’s no surprise that modern measurement technology should be involved, monitoring every step in the process. Everything has to function properly. That’s where Charlotte comes in. For her, reliable technology and outstanding maintenance services are of great importance. And SICK offers both. SICK sensors improve waste transportation. Analyzer systems optimize the incineration and the fl ue gas purifi cation processes. Emissions are monitored continuously. Again an easy going day, no harm done ‒ especially to the environment. We think that‘s intelligent. www.sick.com/waste

Advert_Waste&Recycling_155x235mm_EN_20170812.indd 1 12.08.2017 11:05:29

Für Wirtschaft und Politik ist ein nachhaltiger Umgang mit Abfall, Rohstoffen und Energie eine Frage der Zukunftssicherung. Umwelttechnisches Know-how und Informationen über grundle- gende Entwicklungen sind für den Erfolg entscheidend. Mit der Fachzeitschrift “ReSource – Abfall, Rohstoff, Energie“ sind Sie bestens über nachhaltiges Wirtschaften informiert.

Neben aktuellen Forschungsergebnissen stellt die Fachzeitschrift praxisrelevante Konzepte und Verfahren zur Vermeidung und Verringerung von Umweltbelastungen vor. Verfahren der kon- ventionellen Abfallbehandlung und -entsorgung wie Verbrennung sowie Recycling, Kompos- tierung, Vergärung und Deponierung werden auf ihre Effektivität und Umsetzbarkeit geprüft.

Experten aus dem In- und Ausland diskutieren Erfordernisse und Beispiele für eine zeitgemäße Rohstoffwirtschaft.

Gerne schicken wir Ihnen ein Ansichtsexemplar: RHOMBOS-VERLAG, Kurfürstenstr.

15/16, 10785 Berlin, Tel. 030.261 94 61, Internet: www.rhombos.de, eMail: verlag@rhombos.de

Abfall • Rohstoff • Energie

ReSource

4

201629. Jahrgang ISSN 1868-9531 4. Quartal 2016 Preis 20,00 EUR A 13158 F

R e S ource

(Früher: MÜLLMAGAZIN · ISSN 0934-3482)Abfall • Rohstoff • Energie Fachzeitschrift für nachhaltiges Wirtschaften

RHOMBOS HERAUSGEBER Dipl.-Pol. Bernhard Reiser

REDAKTION Professor Dr.-Ing. Dr. h. c.

Karl J. Thomé-Kozmiensky † Dr.-Ing. Stephanie Thiel Dipl.-Pol. Bernhard Reiser

REDAKTIONSBEIRAT Professor Dr.-Ing. Michael Beckmann Professor Dr. rer. nat. Matthias Finkbeiner Professor Dr.-Ing. Daniel Goldmann Professor Dr.-Ing. Karl E. Lorber Dipl.-Ing. Johannes J. E. Martin Dipl.-Chem.-Ing. Luciano Pelloni Dipl.-Ing. Christian Tebert Professor Dr. Andrea Versteyl

Felix Müller, Jan Kosmol, Hermann Keßler, Michael Angrick und Bettina Rechenberg

Materialflussindikatoren allein liefern keine hinreichende Orientierung für Strategien zur Ressourcenschonung Uwe Lahl

Ein Regulierungsvorschlag zeigt Ansätze, wie die Treibhausgas- Emissionen aus dem Verkehrssektor bis 2050 drastisch reduziert werden können

Thomas Krampitz, Holger Lieberwirth und Michael Stegelmann Die Berücksichtigung des Recyclings im Life Cycle Assessment der Fahrzeugindustrie ermöglicht Produktentwicklern frühzeitige Aussagen zur Ressourceneffizienz von Produkt und Prozess Roland Pomberger und Renato Sarc

Experten aus Forschung und Praxis haben für Österreich den Beitrag der Abfallwirtschaft zur Ressourcenschonung und Ressourceneffizienz untersucht

Wolfgang Rommel, Siegfried Kreibe und Markus Hertel In erster Linie bestimmen Materialmenge und deren Marktwert den Stellenwert und die Limitierungen des Recyclings von Technologierohstoffen

Jan Schlecht, Jan Henning Seelig und Torsten Zeller Die möglichen Auswirkungen eines Pfandsystems für Elektro- und Elektronikkleingeräte müssen noch genauer untersucht werden

Fotos: pixelio.de

Jahresabonnement (4 Ausgaben): 62 Euro (incl. MwSt. und Versand) 30. Jahrgang 2017

221 Online Determination of Elementary and Fractional Waste Composition

Waste Incineration

• Step 7: Fixation of mathematical basic conditions (tolerances, abort criteria) for numerical calculation

In connection with the calculation algorithm and the acceptable computing time the basic conditions for the numerical solver have to be selected. Due to the fact that the simple equations for the target function and the constraints lead to an approximate solution which meets the target function and the constraints at its best (often no exact fulfilment), a non-linear numerical algorithm is needed. The more loops are achieved maximally in each procedure till it is accuracy-controlled aborted; the higher is the required computing performance.

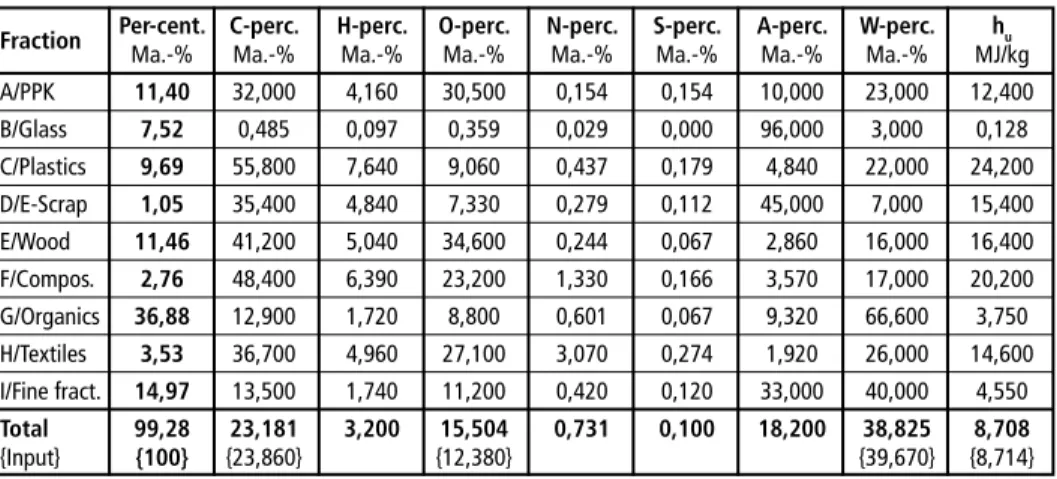

An exemplary result array for a complete cycle of the developed method is shown in Table 2. Bold depicted figures are calculation results, whereas input values are written in curly brackets.

Table 2: Exemplary result array for a calculation cycle of the numerical fraction classification Fraction Per-cent. C-perc. H-perc. O-perc. N-perc. S-perc. A-perc. W-perc. hu

Ma.-% Ma.-% Ma.-% Ma.-% Ma.-% Ma.-% Ma.-% Ma.-% MJ/kg A/PPK 11,40 32,000 4,160 30,500 0,154 0,154 10,000 23,000 12,400 B/Glass 7,52 0,485 0,097 0,359 0,029 0,000 96,000 3,000 0,128 C/Plastics 9,69 55,800 7,640 9,060 0,437 0,179 4,840 22,000 24,200 D/E-Scrap 1,05 35,400 4,840 7,330 0,279 0,112 45,000 7,000 15,400 E/Wood 11,46 41,200 5,040 34,600 0,244 0,067 2,860 16,000 16,400 F/Compos. 2,76 48,400 6,390 23,200 1,330 0,166 3,570 17,000 20,200 G/Organics 36,88 12,900 1,720 8,800 0,601 0,067 9,320 66,600 3,750 H/Textiles 3,53 36,700 4,960 27,100 3,070 0,274 1,920 26,000 14,600 I/Fine fract. 14,97 13,500 1,740 11,200 0,420 0,120 33,000 40,000 4,550 Total 99,28 23,181 3,200 15,504 0,731 0,100 18,200 38,825 8,708 {Input} {100} {23,860} {12,380} {39,670} {8,714}

4. Algorithm independent application of the numerical optimization method

Due to the standardized structure of the described method including the target function and constraints the non-linear numerical optimization algorithm itself is not predeter- mined. In principle there exist only restrictions concerning performance demands in the face of the high number of constraints and stability (result near the global optimum) that allows variations in the initial value.

5. Calculation results and validation approaches

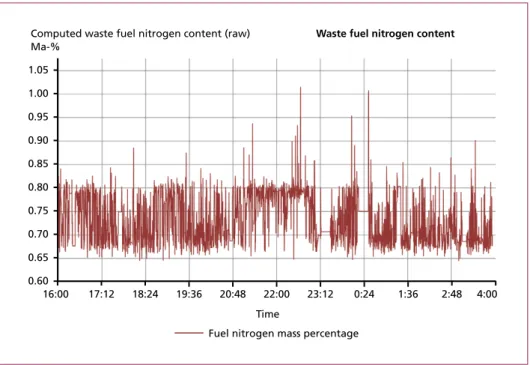

For functionality testing purposes the above described approach was implemented in MS Excel (using the Solver function) and supplied with data from the Online- ba- lancing tool that was installed in a German MSWIP. Generated results for a period of 12 hours with a resolution of ten seconds (historical data) are shown in the diagrams

Tobias Widder, Michael Beckmann, Philip Reynolds

222

Waste Incineration

below (Figure 2 – Figure 4) with focus on computed fraction mass percentages as well as resulting parameters fuel nitrogen and the lower heating value. The imaged solutions are a subset of the complete result.

Numerical computed waste fraction mass percentages Fraction mass percentage

kg/kg

Time 15:5

6 16:1

5

18:2 4 18:4

3 19:0

1 19:2

0 19:3

8 19:5

7 20:1

5 20:3

4 20:5

2 21:1

1 21:2

9 21:4

8 22:0

6 22:2

5 22:4

3 23:0

2 23:2

0 23:3

9 23:5

70:16 0:34

0:53 1:111:30

1:482:072:25 2:44

3:023:21 3:39 0.4

0.2 0.8

0.6 1.2

1.0

0.4

0.2 0.8

0.6 1.2

1.0

15:5 6 15:5

8 16:0

0 16:0

2 16:0

3 16:0

5 16:0

7 16:0

9 16:1

1 16:1

3 16:1

4 16:1

6 16:1

8 16:2

0 16:2

2 16:2

4 16:2

5 16:2

7 16:2

9 16:3

1 16:3

3 16:3

5 16:3

6 16:3

8 16:4

0 16:4

2 16:4

4 16:4

6 16:4

7 16:4

9 16:5

1 16:5

3 16:5

5 16:5

7 16:5

8 17:0

0 17:0

2 Time

Fraction mass percentage kg/kg

16:3 3 16:5

2 17:1

0 17:2

9 17:4

7 18:0

6

I/Fine fract.

H/Textiles G/Organics

F/Compos.

E/Wood D/E-Scrap

C/Plastics B/Glass

A/PPK

Figure 2: Computed fraction composition of incinerating waste in a German MSWIP (16.07.2014)

223 Online Determination of Elementary and Fractional Waste Composition

Waste Incineration

Figure 3: With aid of numerical fraction classification computed fuel-nitrogen content in waste of a German MSWIP (16.07.2014)

16:00 0.90 0.85 0.80 0.75 0.70 0.65

Computed waste fuel nitrogen content (raw) Ma-%

0.60

Time 0.95

1.00 1.05

17:12 18:24 19:36 20:48 22:00 23:12 0:24 1:36 2:48 4:00

Fuel nitrogen mass percentage

Waste fuel nitrogen content

Figure 4: Comparison between lower heating value from Online-balancing tool – input parameter for the numerical fraction classification – and the lower heating value derived from fractions as results of the new method

16:00 17:12 18:24 14

12

10

8

6

4

2

Lower heating value (Comparison balanced – computed by fractions) Lower heating value (raw)

MJ/kg

0 16

19:36 20:48 22:00 23:12 0:24 1:36 2:48 4:00

h_u-balanced h_u_by-fractions

Time

Tobias Widder, Michael Beckmann, Philip Reynolds

224

Waste Incineration

Figure 2 shows, that the target function is fullfilled almost exactly in predominant cases (sum of all fraction mass percentages is one hundred percent). With conformance of constraints in comparison with results there exists another criteria to check plausibi- lity respective success of the method. Precondition for this mentioned conformance of constraints is the consistency of input values. Contradictory would be for instance a data array transmitting a water content of 50 Ma.-% (raw) and simultaneously a lower heating value of 25 MJ/kg (raw). Such a situation as consequence of measurement system failure or balancing mistake precludes the approximately of target function and constraints at the outset, computed values have to be seen as random. Another case are little deviations from the real values, which are unpreventable due to measu- rement system tolerances. Then the optimization algorithm operates corrective and differs to the deffective constraints. In a concrete matter the input values for numerical fraction classification included a raised balanced oxygen content that was caused by measurement value drift (in raw flue gas) for oxygen and carbon dioxide. Oxygen content resulting from calculated fraction mass percentages was lower than balanced input oxygen content – target function and constraints aprroximately were matched – this is also possible the other way around, as shown in Table 2. Consequently, there is a (difficult to quantify) mathematical tolerance limit. For input values discrepancys within this limit a partial compensation ist obtained. Is the discrepancy of the input values outside this limit, generated results are not utilizable. Figure 4 shows via the lower heating value, that in this example the algorithm worked obviously stable.

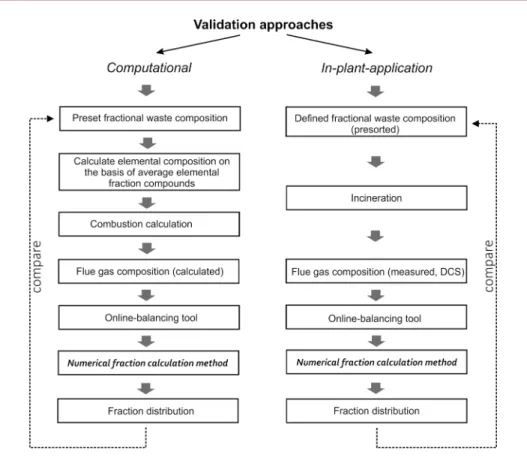

There is a simple way to validate the method theoretically: As reproduced in Figure 5, by using the assumed waste fractions with its elemental components a waste compositi- on can be generated. Achieving a combustion calculation leads to the corresponding flue gas composition. These values, that would be provided from an Online-balancing tool running with data from a real power plant district control system, are available as input parameters for the method. Ultimately, fraction mass percentages that are computed via this method can be compared to with initially assumed fraction mass percentages.

In conclusion there was a good accordance between assumed and computed values.

Approximately seventy to eighty percent of calculation cycles featured a deviation of the particular fractions lower than three percent.

Validating the method in a power plant or testing plant is also workable in an equivalent procedure except there is a real incineration process, which provides required data.

Therefore, defined waste fractions have to be prepared as known waste fuel. According to this reason this validation approach demands significant more effort but is also planned to be accomplished.

6. Online-application potentials

The (almost) instantaneous composition of the waste that is incinerating on the grate is valuable information for the control of waste incineration plants respectively ap- purtenant sub processes like firing or flue gas treatment, if it is provided promptly.

225 Online Determination of Elementary and Fractional Waste Composition

Waste Incineration

More detailed waste fuel specifications are not only helpful for a more precise feeding of auxiliaries but also relevant for a homogenization in the course of firing and may therefore contribute to cost reduction and environmental relief.

The suggested new method is appropriate for online applications with short cycle times. With a commercially obtainable PC and by utilization of a standard optimization algorithm repetition rates of 10 seconds were stable realized. With consideration of the measurement system inertia and the response time of regulator control elements follows, that this developed method is appropriate for the described application and computation of nearly instantaneous values in a procedural meaning.

7. Conclusion

A new method to compute predefined waste fraction percentages of incinerating waste fuel was developed and successfully implemented. It meets the following important criterions:

Figure 5: Options to validate the numerical fraction classification

Tobias Widder, Michael Beckmann, Philip Reynolds

226

Waste Incineration

• Definition of waste fractions as numerical categories is only restricted by accordance between the representative fraction data and the average composition of typical waste fuel within fluctuation ranges. Therefore, this accordance is not given, for example for a cantaloupe bowl fraction as this fruit is no significant part of typical German municipal or household waste. Other areas in the world may have condi- tions that legitimate the introduction of such a fraction. Furthermore there are no compulsory restrictions for selection of kind and number of fraction definition.

• Predefined representative waste fractions contain more assigned data than would be necessary for calculation of its percentages on the basis of online-balancing data.

Thus the knowledge of the waste fractions leads to comprehensive waste fuel data.

• The choice of applied optimization algorithm and the number of constraints is not determined by the method itself. In general each valid and mathematical expressible constraints may be used.

• An online-application is feasible with this method. Computing durations lower than 1 second for one data set obtained with a standard-PC enable nearly process synchronous operational mode.

We also showed and achieved a concrete validation approach that is based on a backward calculation of artificial generated waste and flue gas data with fraction parameters from literature. The results confirmed the feasibility, plausibility and respectable accuracy of this method with an acceptable error rate.

Acknowledgement

This research was supported by the AiF-ZIM gGmbH (support code KF2006413ST2).

8. References

[1] Beckmann, M.; Horeni, M.; Metschke, J.; Krüger, J.; Papa, G.; Englmaier, L.; Busch, M.:

Optimierung von Müllheizkraftwerken durch Einsatz eines Online-Bilanzierungsprogramms.

(Possibilities of Process Optimization in Municipal Solid Waste Incineration Plants by an On- line Balancing Program.) In: Thomé-Kozmiensky, K. J.; Beckmann, M. (Eds.): Optimierung der Abfallverbrennung 2. Neuruppin: TK Verlag Karl Thomé-Kozmiensky, 2005, pp. 219-240;

ISBN: 3-935317-19-0

[2] Beckmann, M.; Horeni, M.; Metschke, J.; Krüger, J.; Papa, G.; Englmaier, L.; Busch, M.: Possi- bilities of Process Optimization in Municipal Solid Waste Incineration Plants by an Online Ba- lancing Program. In: Proceedings of the International Conference on Incineration and Thermal Treatment Technologies – IT3, 09.05. – 13.05.2005, Galveston (USA)

[3] Beckmann, M.; Widder, T.: Balancing and Energy Efficiency of Waste Treatment Processes. In:

Thomé-Kozmiensky, K. J.; Thiel, S. (Eds.): Waste Management – Volume 4 Waste-to-Energy.

Neuruppin: TK Verlag Karl Thomé-Kozmiensky, 2014, pp. 209-228. ISBN 978-3-944310-15-2 [4] Mast, P.-G.: Einfluss der Abfallzusammensetzung auf Schadstoffgehalt und -menge der Ver-

brennungsrückstände (Waste composition influence on contaminant content and quantity of the waste incineration residues), report, 1998

227 Online Determination of Elementary and Fractional Waste Composition

Waste Incineration

[5] Mueller, C.; Frach, M.; Tirkschleit, M., et al.: Fuel-specific on-load boiler cleaning solutions in waste incineration plants – challenges; concepts; experiences. Orlando, Florida: Procee- dings of the 18th Annual North American Waste-to-Energy Conference, May 11 to 13, 2010.

NAWTEC18-3526

[6] Rechberger, H.; Fellner, J.; Cencic, O.: Die treibhauswirksamen Kohlendioxidemissionen und der grüne Stromanteil aus der Abfallverbrennung lassen sich mit der Bilanzenmethode effi- zient bestimmen. (Greenhouse active carbon dioxide emissions and the green power percentage from waste incineration can be determined efficiently by the Balancing method) In: ReSource, Rhombos-Verlag, 2. Quartal 2014, pp. 6-10

[7] Rechberger, H.; Fellner, J.; Cencic, O.: Verfahren zur Ermittlung der Anteile biogener und fossiler Energieträger sowie biogener und fossiler Kohlendioxidemissionen beim Betrieb von Abfallver- brennungsanlagen. (method for determination of biogenic and fossil energy source percentage as well as biogenic and fossil carbon dioxide emissions in operation of waste incineration plants) In: Bilitewski; Schnurer; Zeschmer-Lahl (Eds.) Müll-Handbuch. Erich Schmidt Verlag, 2007, Kapitel 9312, pp. 1-21

[8] Reiche, M.; Graube, F.; Grahl, S.; Beckmann, M.; Kaiser, M.; Taubner, S.; Spiegel, W.; Schind- helm, M.; Baj, P.: Verschmutzung und optimierte Abreinigung der Heizflächen in der Ab- fallverbrennungsanlage Coburg. In: Thomé-Kozmiensky, K. J.; Beckmann, M. (Eds.): Ener- gie aus Abfall, Band 13. Neuruppin: TK Verlag Karl Thomé-Kozmiensky, 2016, pp.173-187.

ISBN 978-3-944310-24-4

[9] Schwarzböck, T.; Rechberger, H.; Fellner, J.: Biomasseanteil in österreichischen Abfallverbren- nungsanlagen. (biomass percentage in Austrian waste incineration plants) In: Thomé-Kozmiensky, K.J.; Beckmann, M. (Eds.): Energie aus Abfall, Band 12. Neuruppin: TK Verlag Karl Thomé- Kozmiensky, 2015, pp. 613-626

[10] Schüttenhelm, W.; Reynolds, P.; Hukriede, J.: Einhaltung verschärfter NOx- und NH3-Grenz- werte bei bestehenden Anlagen – Vorgehen und Lösungsansätze anhand von Praxisbeispielen.

(Compliance with tightened NOx- and NH3-thresholds in existing plants – course of action and solution approaches by means of practical examples) In: Energie aus Abfall, Band 12. Neuruppin:

TK Verlag Karl Thomé-Kozmiensky, 2015

Vorwort

4

Bibliografische Information der Deutschen Nationalbibliothek Die Deutsche Nationalbibliothek verzeichnet diese Publikation in der Deutschen Nationalbibliografie; detaillierte bibliografische Daten sind im Internet über http://dnb.dnb.de abrufbar

Thomé-Kozmiensky, K. J.; Thiel, S.; Thomé-Kozmiensky, E.;

Winter, F.; Juchelková, D. (Eds.): Waste Management, Volume 7 – Waste-to-Energy – ISBN 978-3-944310-37-4 TK Verlag Karl Thomé-Kozmiensky

Copyright: Elisabeth Thomé-Kozmiensky, M.Sc., Dr.-Ing. Stephanie Thiel All rights reserved

Publisher: TK Verlag Karl Thomé-Kozmiensky • Neuruppin 2017

Editorial office: Dr.-Ing. Stephanie Thiel, Elisabeth Thomé-Kozmiensky, M. Sc.

Janin Burbott-Seidel and Claudia Naumann-Deppe

Layout: Sandra Peters, Anne Kuhlo, Ginette Teske, Claudia Naumann-Deppe, Janin Burbott-Seidel, Gabi Spiegel and Cordula Müller

Printing: Universal Medien GmbH, Munich

This work is protected by copyright. The rights founded by this, particularly those of translation, reprinting, lecturing, extraction of illustrations and tables, broadcasting, micro- filming or reproduction by other means and storing in a retrieval system, remain reserved, even for exploitation only of excerpts. Reproduction of this work or of part of this work, also in individual cases, is only permissible within the limits of the legal provisions of the copyright law of the Federal Republic of Germany from 9 September 1965 in the currently valid revision. There is a fundamental duty to pay for this. Infringements are subject to the penal provisions of the copyright law.

The repeating of commonly used names, trade names, goods descriptions etc. in this work does not permit, even without specific mention, the assumption that such names are to be considered free under the terms of the law concerning goods descriptions and trade mark protection and can thus be used by anyone.

Should reference be made in this work, directly or indirectly, to laws, regulations or guide- lines, e.g. DIN, VDI, VDE, VGB, or these are quoted from, then the publisher cannot ac- cept any guarantee for correctness, completeness or currency. It is recommended to refer to the complete regulations or guidelines in their currently valid versions if required for ones own work.