Study of the mechanochemical process to crystalline Cu

2ZnSnS

4powder

Anna Ritscher

a,b, Marc Schlosser

c, Arno P fi tzner

c, Martin Lerch

a,*

aInstitutfürChemie,TechnischeUniversitätBerlin,Straßedes17.Juni135,10623Berlin,Germany

bHelmholtz-ZentrumBerlinfürMaterialienundEnergie,AbteilungKristallographie,Hahn-Meitner-Platz1,14109Berlin,Germany

cInstitutfürAnorganischeChemie,UniversitätRegensburg,Universitätsstr.31,93040Regensburg,Germany

ARTICLE INFO

Articlehistory:

Received17May2016

Receivedinrevisedform26July2016 Accepted5August2016

Availableonline6August2016

Keywords:

A.Semiconductors B.Chemicalsynthesis C.X-raydiffraction D.Crystalstructure D.Defects

ABSTRACT

Kesterite-typeCu2ZnSnS4wassynthesizedfromthecorrespondingbinarysulfidesbyamechanochemi- calrouteinaplanetaryballmill.Thereactionprogressduringthismillingstepwasfollowedwithinatime rangeof10–180minbypowderX-raydiffraction.Inaddition,thecrystallizationofthemilledmaterial wasstudiedinsitubyhigh-temperatureX-raydiffractionmethodsinthetemperaturerangeof300–

500C. Significantdisorder(cationdistribution)wasobservedat500C,stronglydecreasingduring coolingdowntoambienttemperaturewitharateof60K/h.

ã2016ElsevierLtd.Allrightsreserved.

1.Introduction

Systematic analysis of the semiconductor compound Cu2ZnSnS4 (CZTS) and its structural, chemical, and physical propertieshavebeeninthefocusofinterestinthelastfewyears [1–6].Thisquaternarychalcogenideexhibitsagreatpotentialas absorbermaterialforapplicationsinthinfilmphotovoltaics.Due to its suitable properties (optical band gap energy=1.5eV, absorption coefficient in the order of 104cm1 [7–9]) this materialis discussedasa promising low-cost alternativetoIn- containingCuInxGa(1-x)Se2(CIGS).Thecurrentrecordefficiencyof 12.6%wasreachedforCZTS-baseddevicescontainingadditional selenium[10].

Aftersomecontroversiesaboutthecorrectcrystalstructureof Cu2ZnSnS4 it was demonstrated in different studies that this quaternary sulfide adopts the kesterite structure type (space groupI4) [11,12]. Thistetragonalcrystal structure derives from thesphaleritestructuretype(knownforZnSetc.)bydoublingthe c-axisanditconsistsofalternatingcationlayersstackedalongthis axis(seeFig.1).

Thelatticeplanesatz=0andz=1/2areoccupiedbyCuandSnin anorderedmanner,i.e.CuisfoundonWyckoffposition2a(0,0,0) andSnonposition2b(0,0,1/2).RemainingCuandZnatomsare

locatedonlatticeplanesatz=1/4andz=3/4,position2c(0,1/2,1/4) and 2d (0,1/2, 3/4), respectively. Ab initio calculations [13,14]

showedthat,duetoitsverylowformationenergy,thepointdefect complex(CuZn+ZnCu)iseasilyformedandthusCu/Zndisorderhas tobeexpected.Thiswasalsoconfirmedbydiffractionstudieson CZTSpowdersamples,wherepartial[15,16]orcompletedisorder [1]ofCuandZnonthe2cand2dpositionswasreported.

HightemperatureX-raydiffractionmeasurementsofkesterite powderusingsynchrotronradiationshowthatCu2ZnSnS4under- goesastructuralphasetransitionfromthetetragonalkesterite-to the cubic sphalerite-type structure at temperatures above of 866C [2]. Thetransitionleadstoa randomdistributionof the cationsCu,Zn,andSn(spacegroupF43m).Duetotheformationof secondary phases it is challenging to prepare phase-pure CZTS powder, whichis importantfordetailed studiesconcerningthe correlations betweenstructural and electronic properties. Bulk materialofCZTShasbeenusuallyproducedbysolidstatereaction oftheelementsinevacuatedsilicaampoules[1,17].Duetothehigh sulfur vapor pressure it is necessary to apply a well-defined temperatureprogramandhomogenizationisachievedbyasecond annealingstepat750C.Allthesefactorsresultinlongreaction timesandanenhancedpossibilityfortheformationofsecondary phases.

Recently we presented an easy and fast process for the preparation of single phase CZTS powders [16]. Themain idea was the development of a synthesis route at temperatures significantly lower than 750C. This was realized by a

*Correspondingauthorat:

E-mailaddress:martin.lerch@tu-berlin.de(M.Lerch).

http://dx.doi.org/10.1016/j.materresbull.2016.08.006 0025-5408/ã2016ElsevierLtd.Allrightsreserved.

ContentslistsavailableatScienceDirect

Materials Research Bulletin

j o u r n al h o m e p a g e : w w w . e l s e v i e r . c o m / l o c a t e / m a t r e s b u

mechanochemicalapproachandthesynthesisofaprecursorby reactionofthecorrespondingbinarysulfidesCuS,ZnS,andSnSina planetaryballmill.Mechanochemicalprocessesinplanetaryball millsfinda widespreadusein scienceand industrydue tothe feasibility of rapid, highly efficient and usually solvent-free chemical synthesis. Additionally, it is possible todevelop com- pounds that cannot be obtained via a conventional solid-state route[18].

After annealing at 500C in a H2S atmosphere, a highly crystalline product is obtained. A similar mechanochemical process was reported in Ref. [19], where Cu2ZnSnX4 (X=S, Se) bulkmaterialwaspreparedinaballmillstartingfromthemetals andthechalcogens.

Inthiscontributionwepresent amoredetailedstudyofour newtwo-stepsynthesisprocess.Thereactionprocessintheball millasfunctionoftimeaswellasthecrystallizationbehaviorofthe poorlycrystallineCZTSprecursortothecrystallinepowderwith temperatureareinvestigated.

2.Experimental

Sulfide powderswiththechemical formulaCu2ZnSnS4 were preparedbyourmechanicalprocess[16].CuS,ZnS,andSnSwere mixed in a molar ratio of 2:1:1 without any additional fluid mediumandfilledintoan80ml agatejar(including 5grinding ballswithadiameterof20mm).MillingwasperformedinaFritsch PlanetaryMonoMillPULVERISETTE6usingarotationalspeedof 400rpmandmillingtimesofupto180min.Smallamountsofthe sample were withdrawn at time intervals of 10–30min for diffractionanalyses.

Inordertogetahighly crystallineproductasreference,onehalfof theas-milledpowder (millingtime180min)was annealed in a conventional tube furnace equipped with a SiO2-tube in H2S- atmospherefor3hat500C.Afterthistreatment,thesamplewas cooleddown witharateof60K/h.X-raypowderdiffractionwasused forthestructuralcharacterizationofallsamples.Diffractiondata

werecollectedusingaPanalyticalX’PertPROdiffractometer(Bragg- Brentanogeometry,Cu-K

a

radiation).Structuralrefinementswere performedbytheRietveldmethod[20]withtheprogrampackage FullprofSuiteVersion2015[21]by applyingapseudo-Voigtfunction.Thekesterite-typestructure(spacegroupI4)wasusedasstarting modelfortherefinement.

Thesecondhalfofthesamplewasusedfortheinvestigationof thecrystallizationbehaviorofthequaternarysulfideprecursorby insituhigh-temperatureX-raydiffractionwiththehelpofaSTOE STADI Pdiffractometer(Transmission/Debye Scherrer geometry, Mo-K

a

1 radiation). The instrument was equipped witha STOE furnaceusingaNi/CrNithermocouple.Thesamplewasencapsu- latedinanevacuatedsilicacapillaryandinitiallymeasuredatroom temperature(RT,measurementnumber001).Thenthesamplewas heated to 300C with a rate of 50K/min and subsequently measuredat300Cevery10mininordertofollowtheisothermal phaseformationandgrowthofthecrystallites(20measurements, 1min, measurement numbers N=002–021). Afterwards, the temperature was raised to 400C and the powder was again measured every10min(measurementnumbersN=022–042).A furtherheatingstepuptoa temperatureof 500C wasapplied (measurement numbers N=043–062). Againdiffraction pattern were recorded every 10min. As a reference measurement a diffractionpatternoftheemptyfurnacewithoutanysamplewas recorded in order to detect the signals from the furnace (measurementnumberN=000).3.Resultsanddiscussion

Asdescribed in theexperimental section, thefirstsynthesis step to phase pure Cu2ZnSnS4 powder is the reaction of the correspondingbinarysulfides(CuS,ZnS,SnS)inaballmill.Inorder tofollow this reactionprocess, smallamounts of powderwere withdrawn from the grindingbowl by interrupting themilling procedure several times.Fig.2 depictstheXRDpatterns ofthe preparedCZTSpowdersmilledfor10–180min.

Uptoamillingtimeof30minthereflectionsoriginatingfrom thebinarysulfidesarethemainsignalsinthediffractionpatterns.

Duringthisearlystageofmilling,thepowdersofCuS,ZnS,andSnS aremixedtogetherand noreactiontakesplace.After40minof millingtheintensitiesofthereflectionsthatcanbeassignedtothe Fig.1.Unitcelloffullyorderedkesterite-typeCu2ZnSnS4,alloccupiedWyckoff

positionsarelabeled.

Fig.2.Diffractionpatterns(Cu-Karadiation)ofas-preparedsamplesafterthe millingprocessatdifferenttimes(t=10–180min).

binarycompounds begin todecrease, which indicatesthat the solid-statereactionisactivatedandtheproductstartstoform,and after150minitisclearlyseenthatthesignalshavedisappeared.

The sample was further treated up to a total milling time of 180min. However, the diffraction pattern did not change significantly,thus atthis stagethereaction isconsideredtobe terminated.Takingalookatthechangeofthereflectionpositionof themajorreflection a cleartrend to lower2

u

values is visible(2

u

=28.68!28.62),which is anindicationthat thequaternary compound is formed during the reaction in the ball mill. The observed reflection positions of the final as-milled powder correspond to the strongest ones expected for the quaternary compound.However,fromtheobtainedX-raydiffractionpatterns itisnotpossibletoextractunequivocalinformationconcerningthe distributionofthecationsasthemainreflectionsofthekesterite phase (partially or fully ordered) practically have the same positions as the expected ones for a sphalerite-type structure (fully disordered) with the same chemical composition. The superlattice reflections for the kesterite-type phase are rather small(seeFig.4)buttheirtotalabsencepointstoseveredisorderin the milled material. For more unambiguous results additional investigations,forexamplebyEXAFS,wouldbenecessary.Inaddition,asitcanbeclearlyseeninFig.2themillingprocess resultsinverybroadreflections.TheFWHMvaluesincreasewith increasingmillingtimeasshowninFig.3.Profileanalysesrevealed adominantLorentzianshapewhichcanbeattributedtocrystallite sizebroadening.Thecrystallitesizesoftheprecursorpowdersare calculatedusing theScherrer equation (Eq.(1))fromthe strong 112-reflectionat2

u

28.6[22],D

ð2u

Þ¼ Kl

Lcos

u

0 ð1Þwhere

D

(2u

)is the line width at half the maximum intensity(FWHM),KistheScherrer-formfactor,inthisstudyafactorof1 wasused,

l

isthewavelength,Lthemeansizeofthecrystallite, andu

0thediffractionangle.D

(2u

)hastobecorrectedforreflex broadening comingfrom the instrument according toD

ð2u

Þ¼ ðb

2Mb

2IÞ1=2(b

MismeasuredFWHMandb

Iisthecorrectionfactorforinstrumentbroadening).

AsdepictedinFig.3,theparticlesizeafter10minofmillingis calculatedto37nm.Inthefirst90minthecrystallitesizedecreases rapidly,approachingavalueofabout15nm.Onfurthermillingthe crystallitesizeslightly changes reachinga sizeof 11nmafter 180min. In order to confirm the calculated value, TEM

measurementswerecarriedoutwiththissample.Theobserved crystallitesizeswerefoundtobeinarangeof8–13nmwhichisin goodagreementwiththeresultoftheScherrermethod(11nm).

Inordertoprepareahighlycrystallinereferencesample,one halfoftheprecursorpowderwasannealedinatubefurnace(H2S atmosphere)accordingtothesecondstepofourmechanochemical process[16]. Thestructuralparametersof theannealedsample wererefined(seeTables1and2).Asitwasshowninourrecent studies, it is nicely possible to control the composition of the synthesizedpowderwiththemechanochemicalmethod[16,23].

Therefore, for the structural refinement the ideal composition Cu2ZnSnS4wasused.TheX-raypowderdiagramwiththeresultsof theRietveldrefinementisdepictedinFig.4.

Itshouldbementionedthatitisnotpossibletodifferentiate betweenZnandCuusingconventionalX-raypowderdiffraction methods.Consequently,wecanonlydistinguishbetweenCu/Zn andSn.Unfortunately,theamountofpreparedmaterialwasnot sufficientforneutrondiffractionexperiments.Fortherefinements, thefollowingsideconditionswereset:thesumofCu/Znonall positionsmustbe3,thesumofSnonallpositionsmustbe1,andall fourcationpositionshavetobefullyoccupied.

Table 2 lists the final atomic and additional structural parameters.Asexpected, Snwas foundonWyckoffposition2b (0,0,1/2),whereasCu/Znislocatedon2a(0,0,0),2c(0,1/2,1/4), and2d(0, 1/2,3/4)sites.NoSnisfoundonposition2c.On2aand2d sitesverysmallamountsofSn(around1%)arefound.MissingSn onthe2bsiteisreplacedbyCu/Zn.Theseresultsareinagreement withourrecentrefinements[16].

Fig.4. X-raypowderdiffractionpatternwiththeresultsoftheRietveldrefinement usingthekesterite-typestructureasstartingmodel.

Fig.3.FWHMvaluesandcorrespondingcrystallitesizesduringreactionintheball mill.

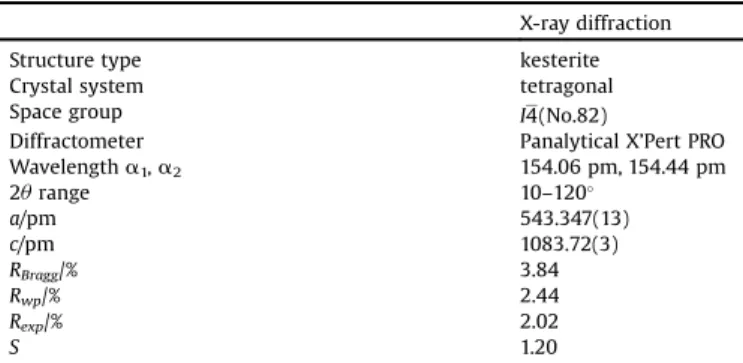

Table1

LatticeparametersofCZTSandresidualvaluesoftheRietveldrefinement.

X-raydiffraction

Structuretype kesterite

Crystalsystem tetragonal

Spacegroup I4(No.82)

Diffractometer PanalyticalX’PertPRO

Wavelengtha1,a2 154.06pm,154.44pm

2urange 10–120

a/pm 543.347(13)

c/pm 1083.72(3)

RBragg/% 3.84

Rwp/% 2.44

Rexp/% 2.02

S 1.20

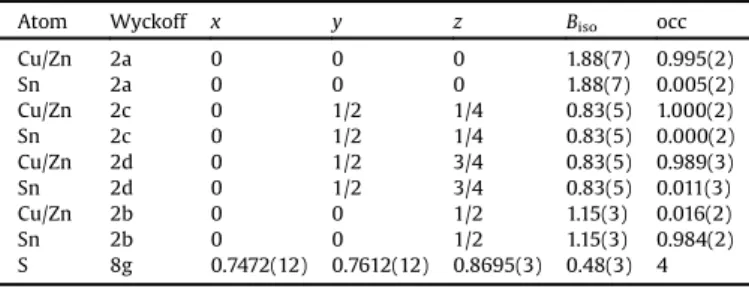

Thesecondhalfoftheas-milledprecursorwasusedtoexamine theeffectof heattreatmentonthecrystallization of mechano- chemicallysynthesizedCZTSpowderbyinsituhigh-temperature X-raydiffraction.Aspointedoutintheexperimentalsection,some seriesofisothermalmeasurementsat300,400,and500Cwere performed.The evolution of theXRD patternscollectedduring heating is depictedin Fig.5 and 6. For a firstoverview, Fig. 5 presents a 3D plot and a rainbow contour plot of all high temperatureX-raypatterns.

Inordertoavoidinformationaloverflow,Fig.6(left)presents onlyonehalf ofmeasuredpatterns(including thepatternwith signalsfromtheemptyfurnace),whereasinFig.6(right)thelastin situ measurement of each annealing temperature (300, 400, 500C)aswellasthediffractionpatternat25C isshown.Isit clearlyseenthatthereflectionsofas-milledCZTSbecamesharper withheatingtime,indicatingincreasedcrystallinity.

Asexpected,increasingtemperatureledtoadecreaseofthefull width at half maximum (FWHM) values (see Fig. 7a). The measurementof thestarting material(25C) givesa calculated crystallitesizeof12nm,whichisingoodagreementwiththeresult fromthediffractometerworkingwithCu-K

a

radiation(SeeFig.4).Having a closer look at the results coming from different annealing temperatures significant differences are found (See Fig.7b).At300Cthecrystallizationisratherslow,thecrystallite sizesbarelyincrease.After3.5hsizesof15nmarereached(see Fig.7b).Asexpected,asignificantlyfasterincreaseisobservedfor 400C, where a final size of 37nm is calculated. In the last annealingstepat500Cthecrystallitesizeisstillincreasingand reachesavalueof50nmafter3.5h.

AsshowninFig.7b,thecrystallitesizeincreasesalmostlinearly at400Candabove.

Usingthefinaldatasetmeasuredat500C(N=062),thecrystal structure was also refined. The X-ray powder patternwith the resultsof the Rietveld refinement is depictedin Fig. 8. Lattice

parameters and residualvalues are summarized in Table 3. As alreadydescribedabove,spacegroupI4 wasusedtogetherwith additional sideconditions ascopperand zinc cannotbedistin- guishedbyconventionalX-raydiffractionmethods.Table4 lists thefinalatomicandotherstructuralparameters.

SnismainlylocatedonWyckoffposition2b,whereasCu/Znis foundontheotherthreecationsites.NosignificantamountofSn wasfoundonpositions2aand2c.Incontrast,asignificantamount of tin (8%)was foundon the 2dsite, whereas missing Sn is replacedbyCu/Znon2b.ForCZTSitisknownthatintrinsicdefects can beeasily formedwhile the kesterite–type structure (space groupI4)ismaintained,e.g.[17,24–26].Theoreticalwork[14,27]

hasshownthatthedefectcluster[Zn2Sn+Sn2+Zn]hasrelatively lowformationenergy(around0.9eV/pair).ThereforeSnCu/Znand Cu/ZnSndefectsshouldbepresentwhenincreasingthetempera- ture.KeepinmindthatZnandCucannotbedistinguishedwith conventional X-ray diffraction techniques. Consequently, the actualdefectclustersinthepresentsamplecannotbedetermined unequivocally.

The refined valuescanbecompared withthevalues forthe above-presentedsampleannealedat500Candcooleddownwith arateof60K/h.At500C,SnCu/ZnandCu/ZnSnanti-sitedefectsare clearlypresent;inthesampleslowlycooleddownto25Chardly anySndisorderisfound.Consequently,itcanbepresumedthat these defectsheal outrapidly during coolingdowntoambient temperature.Thisisalsocomparabletoourrecentneutronpowder diffractionstudyonsamplesannealedforweeks[23]:upto350C no significant disorder of Sn on the remaining three cation positions(2a,2c,2d)isoccurring.

Itcanbeexpectedthattheamountofpointdefectsisincreasing with increasing temperature, finally resulting in a statistical distributionofcopper,zinc,andtin.Asalreadymentioned,sucha high-temperature order-disorder transition was observed by Schorr and Gonzales-Aviles [2],resulting in a cubic sphalerite- typecrystalstructure.

4.Conclusion

Inthisworkourrecentlydevelopedmechanochemicalsynthe- sisprocesstophasepureCZTSpowderwasinvestigatedinmore detail. The reaction of the binary sulfides in the ball millwas followedbyX-raydiffractionmeasurements.Thecrystallitesizeof theas-milledCZTSpowderapproachesavalueof10nmafter3hof milling.Inaddition,thecrystallizationbehaviorwithtemperature wasinvestigatedbyinsituhigh-temperatureX-raydiffraction.At 500C,SnCu/ZnandCu/ZnSnanti-sitedefectsareclearlyobserved.

Their concentrationstronglydecreases when coolingdownthe Table2

RefinedstructuralparametersforCZTSfromX-raydiffraction.

Atom Wyckoff x y z Biso occ

Cu/Zn 2a 0 0 0 1.88(7) 0.995(2)

Sn 2a 0 0 0 1.88(7) 0.005(2)

Cu/Zn 2c 0 1/2 1/4 0.83(5) 1.000(2)

Sn 2c 0 1/2 1/4 0.83(5) 0.000(2)

Cu/Zn 2d 0 1/2 3/4 0.83(5) 0.989(3)

Sn 2d 0 1/2 3/4 0.83(5) 0.011(3)

Cu/Zn 2b 0 0 1/2 1.15(3) 0.016(2)

Sn 2b 0 0 1/2 1.15(3) 0.984(2)

S 8g 0.7472(12) 0.7612(12) 0.8695(3) 0.48(3) 4

Fig.5.3Dplot(left)andrainbowcontourplot(right)forin-situheattreatmentofCZTSprecursorpowderupto500C(Mo-Ka1radiation).Intherainbowcolorcontourplot intensitiesareshownascolorscalewherelowcountsareblue,whilehigherintensitiesareshownasredandyellow.Temperatureincreasesfromthebottomtothetop.(For interpretationofthereferencestocolourinthisfigurelegend,thereaderisreferredtothewebversionofthisarticle.)

Fig.6.EvolutionofthepowderpatternsprobedbyinsituhightemperatureX-raydiffraction(Mo-Ka1radiation).Thenumberofeachpatterncorrespondstothe measurementnumberN(seeexperimentalsection).Pink:300C,blue:400C,green:500C.Thestartingpatternat25Cisshowninblack,thepatternoftheemptyfurnace isdepictedinorange.(Forinterpretationofthereferencestocolourinthisfigurelegend,thereaderisreferredtothewebversionofthisarticle.)

Fig.7.FWHMvalues(a)andcalculatedcrystalsizes(b)fortheCZTSprecursor.

Fig.8. Hightemperature(500C)X-raypowderdiffractionpatternwiththeresultsoftheRietveldrefinement(excludedregions=signalscomingfromthefurnace).

sample.Thecoolingrateof60K/hseemstobethelimit forthe production ofsamples withlow Sn-involveddisorder, which is importantfortheperformanceofCZTSinsolarcells.Foramore detailedanalysisoforderingprocessesuptothedisorderedcubic phase, in situ high-temperature neutron powder diffraction investigationsareplanned.

Acknowledgements

Financial support from the MatSEC graduate school of the HelmholtzZentrumBerlin(HZB)incooperationwiththeDahlem

Research School is gratefully acknowledged. Special thanks to Martin Rohloff (AG Anna Fischer) for performing the TEM measurements.

References

[1]S.Schorr,H.-J.Hoebler,M.Tovar,Eur.J.Mineral.19(2007)65–73.

[2]S.Schorr,G.Gonzalez-Aviles,Phys.StatusSolidiA206(2009)1054–1058.

[3]J.Just,D.Luetzenkirchen-Hecht,R.Frahm,S.Schorr,T.Unold,Appl.Phys.Lett 99(2011)262105/1–262105/3.

[4]S.Chen,X.G.Gong,A.Walsh,S.-H.Wei,Appl.Phys.Lett.96(2010)021902/1–

021902/3.

[5]S.Chen,L.-W.Wang,A.Walsh,X.G.Gong,S.-H.Wei,Appl.Phys.Lett.101(2012) 223901/1–223901/4.

[6]A.J.Jackson,A.Walsh,J.Mater.Chem.A(2014)7829–7836.

[7]S.Chen,X.G.Gong,A.Walsh,S.-H.Wei,Appl.Phys.Lett.94(2009)041903/1–

041903/3.

[8]J.J.Scragg,P.J.Dale,L.M.Peter,G.Zoppi,I.Forbes,Phys.StatusSolidiB245 (2008)1772–1778.

[9]S.Siebentritt,S.Schorr,Prog.Photovolt.20(2012)512–519.

[10]W.Wang,M.T.Winkler,O.Gunawan,T.Gokmen,T.K.Todorov,Y.Zhu,D.B.

Mitzi,Adv.EnergyMater4(2014)1301465/1–1301465/5.

[11]S.Schorr,Sol.EnergyMater.Sol.Cells95(2011)1482–1488.

[12]L.Choubrac,M.Paris,A.Lafond,C.Guillot-Deudon,X.Rocquefelte,S.Jobic, Phys.Chem.Chem.Phys.15(2013)10722–10725.

[13]A.Nagoya,R.Asahi,R.Wahl,G.Kresse,Phys.Rev.BCondens.MatterMater.

Phys81(2010)113202/1–113202/4.

[14]S.Chen,J.-H.Yang,X.G.Gong,A.Walsh,S.-H.Wei,Phys.Rev.B:Condens.Matter Mater.Phys81(2010)245204/1–245204/10.

[15]S.Schorr,M.Tovar,BENSCExperimentalReport,(2006).

[16]A.Ritscher,J.Just,O.Dolotko,S.Schorr,M.Lerch,J.AlloysCompd.670(2016) 289–296.

[17]L.E.ValleRios,K.Neldner,G.Gurieva,S.Schorr,J.AlloysCompd.657(2016) 408–413.

[18]C.F.Burmeister,A.Kwade,Chem.Soc.Rev.42(2013)7660–7667.

[19]D.Pareek,K.R.Balasubramaniam,P.Sharma,Mater.Charact.103(2015)42–49.

[20]H.M.Rietveld,J.Appl.Crystallogr.2(1969)65–71.

[21]J.Rodriguez-Carvajal,AbstractsoftheSatelliteMeetingonPowderDiffraction oftheXV,CongressoftheIUCr,1990,pp.127.

[22]P. Scherrer, Nachrichten von der Gesellschaft der Wissenschaften zu Göttingen,Mathematisch-PhysikalischeKlasse1918(1918).

[23]A.Ritscher,M.Hoelzel,M.Lerch,J.SolidStateChem.238(2016)68–73.

[24]G.Gurieva,M.Dimitrievska,S.Zander,A.Perez-Rodriguez,V.Izquierdo-Roca, S.Schorr,Phys.StatusSolidiC(2015)1–4.

[25]A.Lafond,L.Choubrac,C.Guillot-Deudon,P.Deniard,S.Jobic,Z.Anorg.Allg.

Chem.638(2012)2571–2577.

[26]L.Choubrac,A.Lafond,C.Guillot-Deudon,Y.Moelo,S.Jobic,Inorg.Chem.51 (2012)3346–3348.

[27]S.Chen,A.Walsh,X.-G.Gong,S.-H.Wei,Adv.Mater.(Weinheim,Ger.)25(2013) 1522–1539.

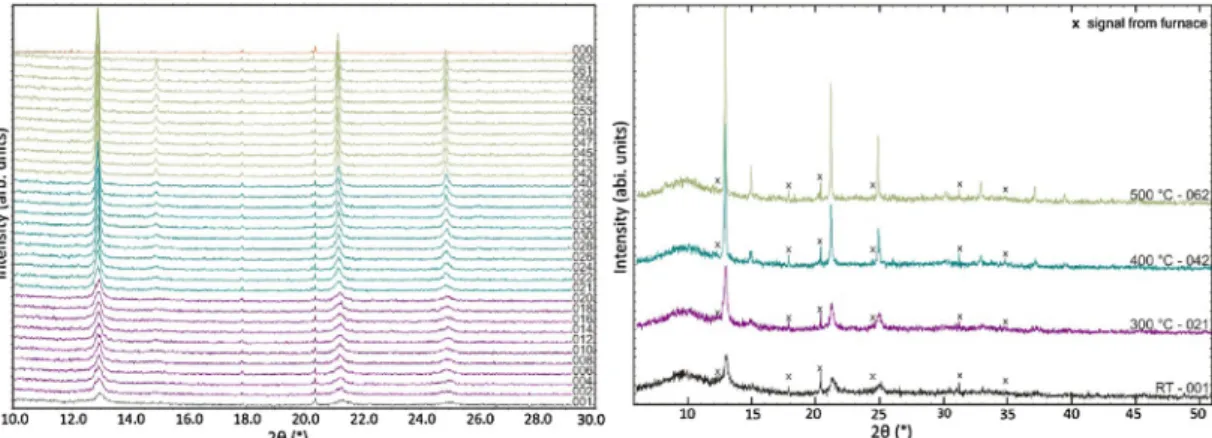

Table3

LatticeparametersandresidualvaluesoftheRietveldrefinementofCZTSat500C.

X-raydiffraction

Structuretype kesterite

Crystalsystem tetragonal

Spacegroup I4(No.82)

Diffractometer STOESTADIP

Wavelength 70.931pm

2urange 10–50

T(Measurement) 500C

a/pm 546.28(3)

c/pm 1090.10(8)

RBragg/% 4.77

Rwp/% 3.84

Rexp/% 3.49

S 1.10

Table4

RefinedstructuralparametersforCZTSat500CfromhightemperatureX-ray diffractiondata.

Atom Wyckoff x y z Biso occ

Cu/Zn 2a 0 0 0 4.00(18) 0.997(11)

Sn 2a 0 0 0 4.00(18) 0.004(11)

Cu/Zn 2c 0 1/2 1/4 4.32(13) 1.000(2)

Sn 2c 0 1/2 1/4 4.32(13) 0.000(2)

Cu/Zn 2d 0 1/2 3/4 4.32(13) 0.922(16)

Sn 2d 0 1/2 3/4 4.32(13) 0.080(16)

Cu/Zn 2b 0 0 1/2 2.36(8) 0.084(11)

Sn 2b 0 0 1/2 2.36(8) 0.918(11)

S 8g 0.748(6) 0.757(5) 0.8699(10) 1.94(9) 4