Incineration Residues

Utilization of Incineration Bottom Ash in Road Constructions

Jirˇí Hykš and Michal Šyc

1. IBA composition and properties ...732

2. Use of IBA as unbound aggregates ...733

2.1. Pre-treatment and improvement of geotechnical and environmental properties ...733

2.2. Environmental and functional requirements ...734

2.3. Legal situation in different countries ...735

2.4. Examples of utilisation of IBA in road constructions ...737

2.5. Final remarks ...740

3. Literature ...740 Incineration bottom ash (IBA) production in Europe is roughly 19 million tons per year while this amount is expected to increase further in future.

Rather than a waste to be landfilled, IBA is a valuable resource that can replace raw materials and from which valuable metals can be recovered and recycled. Apart from a small fraction of unburnt organic material (typically < 1 %), IBA consists primarily of two types of resources: metals (typically 8 – 10 % as ferrous metals and 2 – 5 % as non-ferrous metals) and mineral fraction (sometimes referred to as aggregates), which is a heterogeneous mixture of non-combusted materials such as waste glass, waste/

soil minerals and melt and sintered products of various mineral composition, all with highly variable particle sizes. The mineral fraction typically constitutes 80 – 85 % of the IBA [1].

Metals have been recovered routinely from IBA with increasingly efficient equipment, regardless of the origin of the IBA being an incinerator equipped with a dry or wet discharge (quenching) [4, 8, 12]. As for the mineral fraction, the utilisation options include [7]:

• Use as unbound aggregates;

• Use in cement bound applications;

• Use in bitumen bound applications;

• Use as an admixture in cement manufacturing; and

• production of alkali-activated materials (geopolymers), adsorbents, ceramics, glass-ceramics, bricks, tiles and numerous types of low-strength building elements in general.

Incineration Residues

Nevertheless, except for the use as unbound aggregates (and occasionally as cement bound applications), none of the above-mentioned options has shown truly feasible on both a large scale and for the bulk of IBA as these processes often require a certain type of material with a certain quality (both environmental and technical). In addition, the majority of bottom ash originating from dry discharge systems has been landfilled after the recovery of metals and, therefore, dry IBA will not be discussed further.

The main management option applicable to the bulk of quenched IBA (which is the dominant IBA type produced in Europe) on a large scale has been the use of IBA as unbound aggregates; i.e., replacing virgin raw materials in specific construction works, such as subbase in road constructions. This is reflected by this paper which discusses the composition and properties of quenched IBA, the necessary pre-treatment, the functional and environmental protection aspects of IBA application as unbound aggregates, the legal situation in selected countries as well as few examples of good practice.

1. IBA composition and properties

Given the variation in waste composition, furnace configuration, combustion tempe- rature, retention time and quenching process, the elemental composition of IBA from different origins is surprisingly similar as bulk chemical analyses of ashes from different plants usually fall within one order of magnitude. On the other hand, the physical appearance of IBA is rather inhomogeneous and may – depending on the quenching technology, national consumer’s habits and the efficiency of separate collection system – vary from a granular material to large fused lumps [13].

Generally speaking, fresh quenched IBA consists of two major groups of particles: the non-combusted waste products with high melting points such as refractory glass, waste/

soil minerals and waste metals and the melt products formed as a consequence of high- temperature combustion. The melt products form lumps with grain sizes in the range from mm to cm and include the products resulting from melting/partial melting of the waste and the minerals that have crystallised from the melt. The melt products consist of silicate glasses, melilite-group minerals, pyroxenes, spinels, oxides, and carbonates.

High glass-content of IBA results from rapid cooling (quenching) of the hot, partly molten material. Because of the rapid cooling, the major part of the silicate material consists of porous, thermally fractured particles, with fractures originating from the escape of gases during combustion and from quenching. The phase assemblage that is present after rapid combustion, cooling, and quenching, is far from thermodynamic equilibrium, and it is characteristically meta-stable under ambient conditions [2 and references therein]. Therefore, fresh IBA (when quenched) is generally unsuitable for direct use as it is and should be processed before being used. In addition to the removal of the ferrous and non-ferrous metals, the geotechnical and environmental properties of the material need to be improved prior to its utilisation.

Incineration Residues

2. Use of IBA as unbound aggregates 2.1. Pre-treatment and improvement of geotechnical and environmental properties

When IBA is intended for application as unbound aggregates, a significant stabilisation of (quenched) IBA may be achieved spontaneously via a natural process referred to as weathering (or ageing) which is, by far, the most used process in the management of IBA, since it is applicable to the large mass of IBA at low costs. Weathering consists of a number of sub-processes, including dissolution/precipitation of salts, glass corrosi- on, oxidation of elemental metals, hydrolysis of oxides, slaking of lime, carbonation, hardening and hydraulic cementation reactions, the formation of clay-like minerals from glasses, sorption, complexation, etc. [6].

Typically, weathering takes place during stockpiling of IBA in open air conditions (Figure 1) for a minimum of 3 – 4 weeks, although the more common weathering period may last from several months up to a year, depending on climate conditions and storage space capacity issues.

As many of the above-mentioned processes are exothermic (temperatures up to 85 – 90 ºC for several weeks are not uncommon inside large IBA piles), the initial moisture content of IBA decreases, partly thanks to evaporation and partly thanks to water-consuming chemical reactions. A key part of the weathering process includes carbonation, which – most importantly – results in a decrease of the IBA’s own pH in contact with water to pH 9 – 10.5 (initially above pH 12) and, in turn, leads to further improvement of geotechnical properties of IBA and to reduced leaching of some cation- forming trace metals (e.g. Cd, Cu, Pb, and Zn). On the other hand, some oxyanion- forming elements such as Sb and Cr may become mobilised if pH drops below 10.

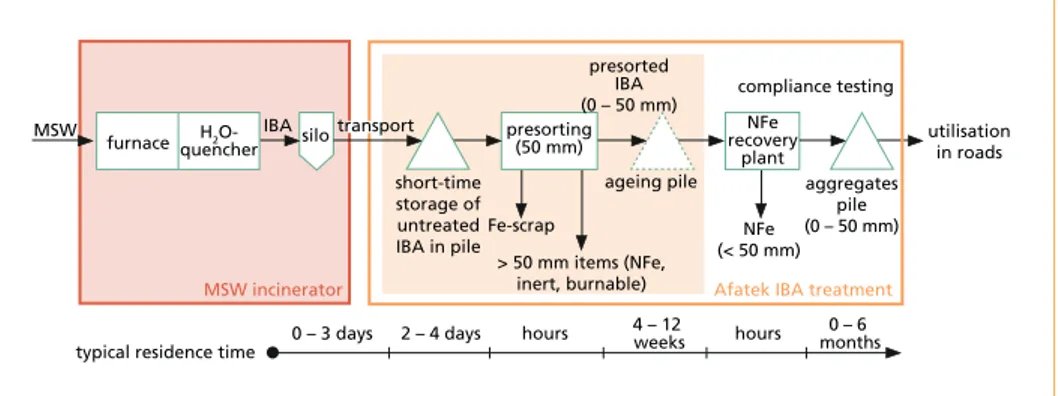

An example of a time-scale starting at the incineration plant and ending at the pile of aggregate ready to be used in road constructions is given in Figure 2.

Figure 1:

Weathering of IBA after the recovery of large ferrous metals and prior to the recovery of non- ferrous metals (Afatek, DK), Size of a pile: 5,000 tons IBA

Incineration Residues

Figure 2: Overview of different stages in IBA treatment with indicative typical residence time

Source: Nørgaard, K. P.; Hyks, J.; Mulvad, J. K.; Frederiksen, J. O.; Hjelmar, O.: Optimizing large-scale ageing of municipal solid waste incinerator bottom ash prior to the advanced metal recovery: Phase I: Monitoring of temperature, moisture content, and CO2 level. In: Waste Management 85, 2019, pp. 95-105

Apart from the release of metals and salts (discussed in next section), the main poten- tial risk to human health is exposure by direct contact (mainly if the IBA has not been carbonated and is strongly alkaline) and by ingestion by children (due to content of potentially hazardous elements and, of course, also due to its alkaline nature). Therefo- re, pre-treatment must include carbonation, and application conditions must prevent direct exposure to humans (i.e. use on the surface is not recommended).

2.2. Environmental and functional requirements

After pre-treatment IBA has excellent mechanical properties, including a well-graded particle size distribution, that allows it to replace virgin materials (sand, gravel, crushed rock) in several structural engineering applications such as subbase in road construction and under squares/public places and highway ramps as well as in noise reduction barriers. IBA does, however, have content of mainly inorganic substances that may potentially be harmful to the environment and human health, if the IBA is not pre-treated sufficiently and used under proper conditions.

The main potential risk to the environment is the release of salts (mainly chlorides and sulphates) and trace elements into percolating rainwater that may subsequently migrate to contaminate soil, groundwater and surface water. Therefore, the pre-treatment of IBA should aim to reduce or minimise the leaching of contaminants, and application conditions for IBA as unbound aggregates should be restricted in such a manner that unacceptable impacts on groundwater and surface water from leaching of substances are prevented.

When using risk-related scenario calculations to set leaching-based regulatory criteria for the use of IBA as unbound aggregates, the conditions imposed must be incorporated into the calculation scenarios, and the resulting criteria must reflect these conditions, see e.g. [11].

furnace

MSW H2O-

quencherIBA silo presorting

(50 mm) presorted

IBA (0 – 50 mm)

ageing pile

compliance testing recoveryNFe

plant

NFe (< 50 mm) Afatek IBA treatment Fe-scrap

> 50 mm items (NFe, inert, burnable) MSW incinerator

typical residence time 0 – 3 days 2 – 4 days hours 4 – 12

weeks hours 0 – 6 months aggregates

pile (0 – 50 mm)

utilisation in roads short-time

storage of untreated IBA in pile transport

Incineration Residues

2.3. Legal situation in different countries

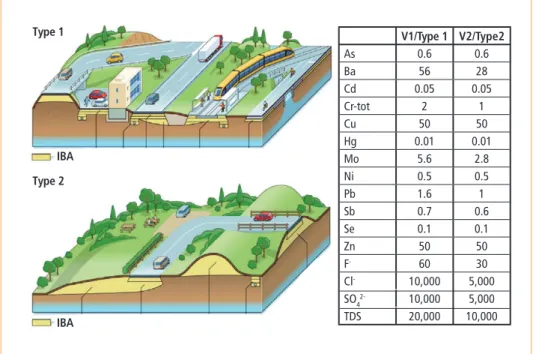

Currently, there are no environmental protection criteria for the use of IBA as unbound aggregates at EU level, but several of the EU Member States have developed national guidelines or regulatory quality criteria for the use of IBA (and often also other aggre- gates) in unbound applications. The quality criteria, which typically include limit values on both content and leaching of certain substances, are in most cases accompanied by certain conditions on the use, and in several cases, there are more than one set of limit values, each reflecting different conditions of use – less restrictive limit values corresponding to more restrictive use conditions. For instance, utilization scenarios with low-permeable top cover allow for a thicker layer of IBA or higher leaching limit values compared with scenarios where the infiltration into the application is less limited.

The latter is being illustrated graphically in Figure 3.

V1/Type 1 V2/Type2

As 0.6 0.6

Ba 56 28

Cd 0.05 0.05

Cr-tot 2 1

Cu 50 50

Hg 0.01 0.01

Mo 5.6 2.8

Ni 0.5 0.5

Pb 1.6 1

Sb 0.7 0.6

Se 0.1 0.1

Zn 50 50

F- 60 30

Cl- 10,000 5,000

SO42- 10,000 5,000

TDS 20,000 10,000

Type 1

IBA

IBA Type 2

Figure 3: Examples of allowed utilization options for IBA in France characterized as Type 1 or Type 2 with associated leaching limits values compared with the results of a batch leaching test in accordance with EN 12457-2

Source: Arrêté du 18 novembre 2011 relatif au recyclage en technique routière des mâchefers d‘incinération de déchets non dangereux, JORF n°0277 du 30 novembre 2011 page 20152 texte n° 10, 2011

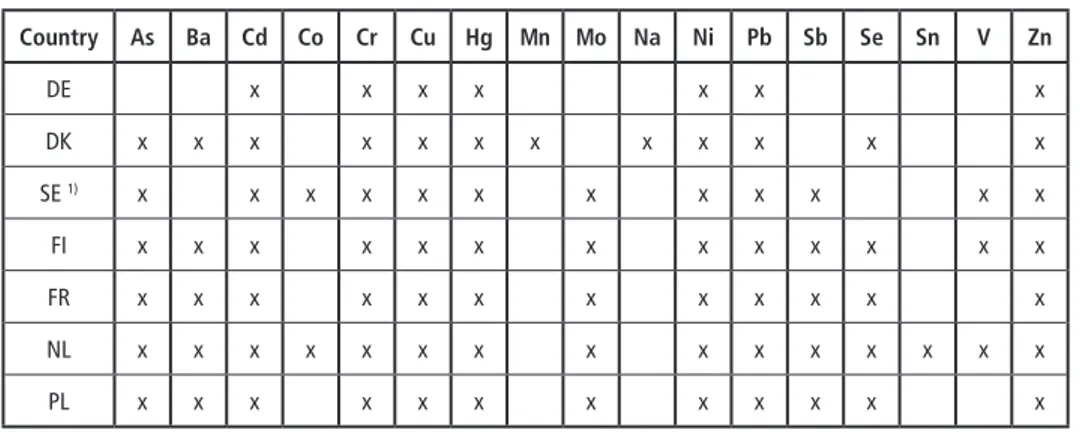

Detailed information regarding the legislation situation in the different EU Member States can be found in a recent publication by Blasenbauer and Huber [3]. For the purpose of illustration, Table 1 gives a consolidated overview of elements monitored in leachate in selected countries; only metals and metalloids are shown. The actual

Incineration Residues

leaching limit values are not shown in Table 1 as these are often related to different types of applications (and conditions for the use) as well as to different types of leaching tests used in different Member States and thus not directly comparable.

Table 1: Illustrative overview of selected inorganic parameters (with the exception of salts) mo- nitored in different countries in leachate from IBA prior to the potential utilization in e.g. road constructions

Country As Ba Cd Co Cr Cu Hg Mn Mo Na Ni Pb Sb Se Sn V Zn

DE x x x x x x x

DK x x x x x x x x x x x x

SE 1) x x x x x x x x x x x x

FI x x x x x x x x x x x x x

FR x x x x x x x x x x x x

NL x x x x x x x x x x x x x x x

PL x x x x x x x x x x x x

1) Proposed by Avfall Sverige in a recently developed guidance

In addition to the guidelines and regulatory criteria aimed at environmental protection, the national authorities responsible for the application of unbound aggregates in e.g.

road construction often define some functional geotechnical criteria that IBA must fulfil to be accepted as a construction material. Again, these functional geotechnical criteria may vary in different countries and some criteria defined in 2012 by the Danish Road Directorate for such uses are listed below as an example:

• No particle > 45 mm (crushing may be applied on-site);

• Content of particles > 31.5 mm is < 15 %;

• Content of particles < 0.063 mm is < 9 %;

• A normative reference to EN 13285: GN (PSD curve), OC85 (oversize fraction), UF9 (max. amount of fine particles), and LFN (min. amount of fine particles);

• TOC < 3 % (based on EN 13137), and

• < 15 cm3/kg of material with density smaller than water (based on EN 933-11) in a representative sample of the fraction 4/63 mm.

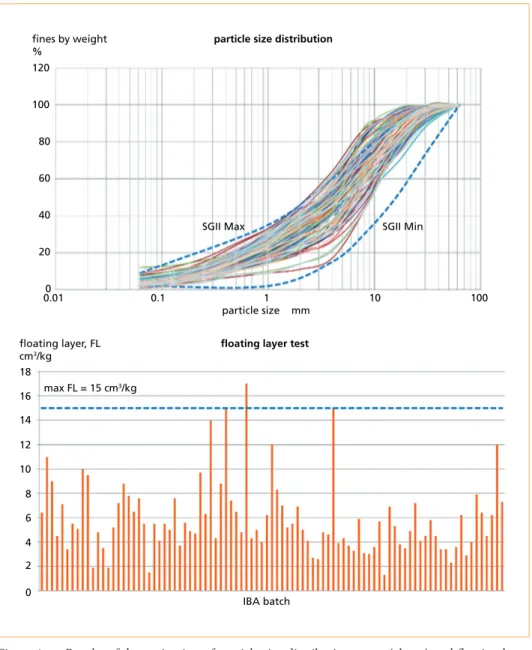

For illustration, the results of the regular monitoring of IBA done by Afatek since 2012 prior to the utilization in constructions are shown in Figure 4. Each dataset represents a batch of 5000 tons IBA (here, particle size distribution curve and floating layer are shown); according to the Danish law, IBA from each incinerator must be collected, processed and tested (incl. environmental tests) in batches of maximum 5,000 tons.

Incineration Residues

Figure 4: Results of determination of particle size distribution curve (above) and floating layer test (below) for Danish IBA

Source: Afatek AS

2.4. Examples of utilisation of IBA in road constructions

The use of IBA in unbound applications is well established in many countries since metal-sorted and weathered IBA complies with technical requirements for the use in road base and subbase. A comprehensive overview of no less than 20 different field tests using IBA in unbound applications in Sweden, France, Denmark, USA, The United Kingdom, Italy and The Netherlands is provided by Lynn et al. [9].

0 20

0.01 0.1 1

particle size mm

SGII Max SGII Min

10 100

40 60 80 100 120

fines by weight

%

0 2

IBA batch 4

6 8 10 12 14 16 18

floating layer, FL cm3/kg

max FL = 15 cm3/kg

particle size distribution

floating layer test

Incineration Residues

The results of the individual studies are not discussed in detail here, although it should be noted that they confirm good functional properties of IBA used in unbound appli- cations. For the purpose of illustration, the results of a recent Danish project focused on evaluation of the technical properties of IBA – not included in the above-mentioned review article – are presented in larger detail, as they show that (i) the use of IBA in road construction may be allowed in roads with higher traffic load (more than 600 trucks/day) and (ii) the application of IBA may be moving up towards the use in the unbound base-layer (i.e., not only to be used as subbase).

Currently, the use of IBA in Denmark is permitted in subbase (i.e. replacing low-quality materials such as soil/sand) of roads projected up to the 600 trucks/day load capacity (so-called T4 – class). In order to test IBA performance in high-load scenarios as well as to test its performance in different technical layers of the road, Danish Road Di- rectorate in cooperation with Afatek have built an experimental full-scale test road in Copenhagen in connection with the expansion of harbour area where ~10 million m3 of soil are to be moved using trucks over 15 – 20 years. The test road has been const- ructed in 2012 and the annual expected traffic load over the 15-year period places the road in the highest traffic class, T7 (over 1,500 trucks per day).

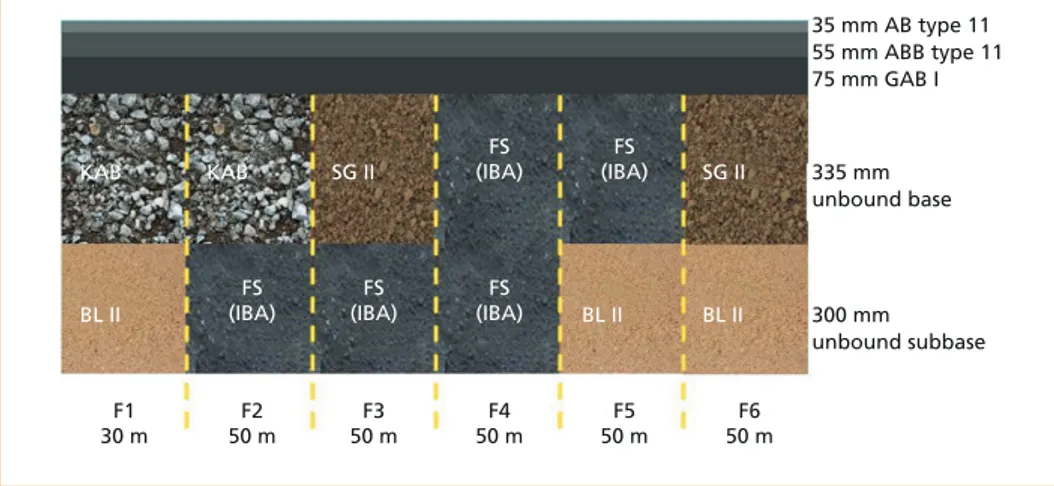

The test road was constructed as a two-direction road with a heavy lane for incoming trucks and a light lane for leaving trucks. Each truck is registered/weighted on the way in and out (Table 2). The test road monitoring strip is 280 m long and consists of 6

Date # of workdays

load-in load-out

# of vehicles tons

Jul-I2 22 242,775 105,259 4,462

Aug-12 23 333,180 146,055 6,297

Sep-12 20 282,029 134,253 5,685

Okt-12 23 285,176 84,014 6,197

Nov-12 22 275,125 107,411 6,012

Dec-12 17 218,653 82,347 4,488

Jan-l3 22 345,683 130,996 7,200

Feb-13 20 299,902 115,269 6,221

Mar-13 19 274,263 106,528 6,057

Apr-13 20 216,556 82,100 4,685

May-13 21 288,012 109,410 5,951

Jun-I3 19 237,329 90,395 5,022

Jul-I3 23 312,895 117,377 6,347

Aug-I3 22 312,660 118,359 6,474

Sep-13 21 370,084 141,717 7,810

Okt-13 23 483,556 179,820 9,819

Nov-13 21 397,253 155,290 8,405

Dec-13 19 275,562 104,913 5,794

Jan-14 22 386,599 145,641 7,858

Feb-14 20 355,282 136,279 7,308

Mar-14 21 360,989 135,978 7,346

Apr-14 19 330,074 124,285 6,664

May-14 21 381,289 139,354 7,472

Jun-l4 20 236,121 87,747 4,637

Total 500 7,501,047 2,880,797 154,211

Table 2:

Registered traffic load on the test road at Nordhavn, Copenhagen over the first two years after the construction

Source: Vejdirektoratet

Incineration Residues

individual sections (1 x 30 m and 5 x 50 m) where different combinations of materials (natural sand [BL II], natural gravel [SG II], crushed concrete [KAB], and IBA) were used in the construction of both the unbound subbase and the unbound base. The thickness of the unbound subbase and the unbound base is 300 mm and 335 mm, respectively. The asphalt layer (total thickness 165 mm) consists of three individual material types (35 mm, 55 mm and 75 mm from the top to the bottom); Figure 5.

KAB KAB SG II SG II

BL II BL II

BL II

F1

30 m F2

50 m F3

50 m F4

50 m F5

50 m F6

50 m

35 mm AB type 11 55 mm ABB type 11 75 mm GAB I

335 mm unbound base

300 mm unbound subbase FS

(IBA)

FS (IBA)

FS (IBA)

FS (IBA)

FS (IBA)

Figure 5: Schematic cross-section of the different road sections (F1 to F6) of the test road in Copenhagen. KAB: crushed concrete; SG II: natural gravel; BL II: natural sand

Source: Caroline Hejlesen, Vejdirektoratet

As part of the performance monitoring, the following parameters are measured regularly for each test cross-section of the test road:

• E-modulus (Young’s modulus) in the unbound sub-base, the base, as well as in the asphalt layer;

• Rutting; and

• Smoothness.

Based on the measurements it is confirmed yet again that IBA is a good material for use as unbound subbase (i.e. replacement for sand). In addition, the full-scale measu- rements have shown much higher bearing capacity of the IBA than anticipated based on the laboratory measurements. In fact, it was shown that IBA can be – without any problems – used in traffic class roads higher than T4 (here, realistic T6 has been tested).

Values for both the smoothness and the rutting were well within the acceptance limits for these types of roads/loads. For instance, the rutting measured over the course of first two years in the heavy lane was 2.5 – 3.5 mm while in the light lane it was appro- ximately 1.6 mm; typically, values up to 10 mm are considered as normal rutting is similar scenarios.

The positive results for test fields F4/F5, where IBA is used also in the base layer instead of KAB or SG II) indicate that IBA ought to be considered in construction of the base

Incineration Residues

layer too. In fact, the very last monitoring data from 2016 indicate that IBA has better bearing properties than SG II (KAB is the best). IBA moving towards the utilization in the base layer, thereby replacing higher quality materials such as natural gravel (here SG II) would both increase the market price of the IBA-gravel and save some natural resources (there is a limited amount of natural gravel in current mines in DK).

Naturally, in order to obtain even better bearing properties, the IBA used in the base layer may be reinforced by milling in cement in the top 10-20 cm. This would result in extreme bearing capacity and also limit the leaching; this kind of improvement is already accepted as a solution for construction of sites/public places but not yet for the roads.

2.5. Final remarks

Metal-sorted, weathered IBA is/can be used to replace natural materials in certain types of constructions; e.g. in subbase of road constructions. Recently, it was shown that the geotechnical properties allow for using the IBA in high-load roads while the use in the base layer may be possible as well. It should be understood that IBA can in no way replace a substantial part of the used natural resources since, for instance, the entire annual European production of IBA accounts for less than a half of the demand for natural construction materials in Denmark alone. Nevertheless, since the IBA is (and will be) produced inevitably as part of waste management solution, its utilization in fitting applications – thus redirecting the IBA from simple landfilling as done in many countries – helps to close the material loop, saves resources as well as landfill space.

3. Literature

[1] Arrêté du 18 novembre 2011 relatif au recyclage en technique routière des mâchefers d‘incinération de déchets non dangereux, JORF n°0277 du 30 novembre 2011 page 20152 texte n° 10, 2011 [2] Bayuseno, A. P.; Schmahl, W. W.: Understanding the chemical and mineralogical properties of

the inorganic portion of MSWI bottom ash. In: Waste Management 30[8-9], 2010, pp. 1509-1520 [3] Blasenbauer, D.; Huber, F.: Utilisation of Incineration Bottom Ash and Legal Requirements in

the Member States. In: The IRRC 2019 conference proceedings

[4] Böni, D; Morf, L.: Thermo-recycling – Efficient Recovery of Valuable Materials from Dry Bottom Ash. In: Holm, O.; Thomé-Kozmiensky, E. (eds.): Removal, Treatment and Utilisation of Waste Incineration Bottom Ash. Thomé-Kozmiensky Verlag GmbH, Neuruppin, 2018, pp. 25-37 [5] Cewep: Bottom Ash Factsheet, http://www.cewep.eu/2017/09/08/bottom-ash-factsheet/

[6] Freyssinet, P.; Piantone, P.; Azaroual, M.; Itard, Y.; Clozel-Leloup, B.; Guyonnet, D.; Baubron, J.C.:

Chemical changes and leachate mass balance of municipal solid waste bottom ash submitted to weathering. In: Waste Management, 22(2), 2002, pp. 159-172

[7] Hykš, J.; Hjelmar, O.: Utilisation of Incineration Bottom Ash (IBA) from Waste Incineration – Prospects and Limits. In: Holm, O.; Thomé-Kozmiensky, E. (eds.): Removal, Treatment and Utilisation of Waste Incineration Bottom Ash. Thomé-Kozmiensky Verlag GmbH, Neuruppin, 2018, pp. 11-23

[8] Kallesøe, J.; Jensen, S.D.: Recovery of Resources in Bottom Ash – Semi Dry Concept. In: Holm, O.; Thomé-Kozmiensky, E. (eds.): Removal, Treatment and Utilisation of Waste Incineration Bottom Ash. Thomé-Kozmiensky Verlag GmbH, Neuruppin, 2018, pp. 39-46

Incineration Residues [9] Lynn, C. J.; Ghataora, G. S.; Dhir, R. K.: Municipal incinerated bottom ash (MIBA) characteristics

and potential for use in road pavements. In: International Journal of Pavement Research and Technology 10, 2017, pp. 185-201

[10] Nørgaard, K. P.; Hyks, J.; Mulvad, J. K.; Frederiksen, J. O.; Hjelmar, O.: Optimizing large-scale ageing of municipal solid waste incinerator bottom ash prior to the advanced metal recovery:

Phase I: Monitoring of temperature, moisture content, and CO2 level. In: Waste Management 85, 2019, pp. 95-105

[11] Savyen, H.; Eder, P.; Garbarino, E.; Muchova, L.; Hjelmar, O.; van del Sloot, H.; Comans, R.; van Zomeren, A.; Hyks, J.; Oberender, A.: Study on methodological aspects regarding limit values for pollutants in aggregates in the context of the possible development of end-of-waste criteria under the EU Waste Framework Directive. In: Rep. No. JRC91036, European Commission, Joint Research Centre, Institute for Prospective Technological Studies, 2014

[12] Stockinger, G.: Direct Wet Treatment of Fresh, Wet-Discharged Grate Ash from a Waste Incine- ration Plant. In: Holm, O.; Thomé-Kozmiensky, E. (eds.): Removal, Treatment and Utilisation of Waste Incineration Bottom Ash. Thomé-Kozmiensky Verlag GmbH, Neuruppin, 2018, pp.

47-52

[13] Šyc, M.; Simon, F.G.; Biganzoli, L.; Grosso, M.; Hykš, J.: Resource Recovery from Incineration Bottom Ash: Basics, Concepts, Principles. In: Holm, O.; Thomé-Kozmiensky, E. (eds.): Remo- val, Treatment and Utilisation of Waste Incineration Bottom Ash. Thomé-Kozmiensky Verlag GmbH, Neuruppin, 2018, pp. 1-10

Contact Persons

Ing. PhD Jiří Hykš

Danish Waste Solutions ApS Partner

Agern Allé 3 2970 Hørsholm DENMARK +45 26687051 jhy@danws.dk Ing. PhD Michal Šyc

Institute of Chemical Process Fundamentals of the CAS, v.v.i.

Head of Department of Environmental Engineering Rozvojová 135

16500 Prague CZECH REPUBLIC +420 220 390261 syc@icpf.cas.cz

Bibliografische Information der Deutschen Nationalbibliothek Die Deutsche Nationalbibliothek verzeichnet diese Publikation in der Deutschen Nationalbibliografie; detaillierte bibliografische Daten sind im Internet über http://dnb.dnb.de abrufbar

Thiel, S.; Thomé-Kozmiensky, E.; Winter, F.; Juchelková, D. (Eds.):

Waste Management, Volume 9 – Waste-to-Energy –

ISBN 978-3-944310-48-0 Thomé-Kozmiensky Verlag GmbH

Copyright: Elisabeth Thomé-Kozmiensky, M.Sc., Dr.-Ing. Stephanie Thiel All rights reserved

Publisher: Thomé-Kozmiensky Verlag GmbH • Neuruppin 2019 Editorial office: Dr.-Ing. Stephanie Thiel, Elisabeth Thomé-Kozmiensky, M.Sc.

Layout: Claudia Naumann-Deppe, Janin Burbott-Seidel, Sarah Pietsch, Ginette Teske, Roland Richter, Cordula Müller, Gabi Spiegel Printing: Universal Medien GmbH, Munich

This work is protected by copyright. The rights founded by this, particularly those of translation, reprinting, lecturing, extraction of illustrations and tables, broadcasting, micro- filming or reproduction by other means and storing in a retrieval system, remain reserved, even for exploitation only of excerpts. Reproduction of this work or of part of this work, also in individual cases, is only permissible within the limits of the legal provisions of the copyright law of the Federal Republic of Germany from 9 September 1965 in the currently valid revision. There is a fundamental duty to pay for this. Infringements are subject to the penal provisions of the copyright law.

The repeating of commonly used names, trade names, goods descriptions etc. in this work does not permit, even without specific mention, the assumption that such names are to be considered free under the terms of the law concerning goods descriptions and trade mark protection and can thus be used by anyone.

Should reference be made in this work, directly or indirectly, to laws, regulations or guide- lines, e.g. DIN, VDI, VDE, VGB, or these are quoted from, then the publisher cannot ac- cept any guarantee for correctness, completeness or currency. It is recommended to refer to the complete regulations or guidelines in their currently valid versions if required for ones own work.