TK Verlag Karl Thomé-Kozmiensky

Dorfstraße 51

D-16816 Nietwerder-Neuruppin

4ELs&AX E-Mail: tkverlag@vivis.de

Waste Management

7ASTE-ANAGEMENT6OLUMEs7ASTE-ANAGEMENT6OLUMEs#$7ASTE-ANAGEMENT6OLUME 7ASTE-ANAGEMENT6OLUMEsWaste Management, Volume 4sWaste Management, Volume 5

200.00 EUR

save 85.00 EUR

Package Price

Order your book on www. .de

or

Karl J. Thomé-Kozmiensky

WASTE MANAGEMENT

Luciano Pelloni

Thomé-Kozmiensky und PelloniWASTE MANAGEMENT

Volume 1 Eastern European Countries Karl J. Thomé-Kozmiensky

Volume 2

WASTE MANAGEMENT

Luciano Pelloni

Waste Management Recycling Composting Fermentation Mechanical-Biological Treatment Energy Recovery from Waste Sewage Sludge Treatment Thomé-Kozmiensky und PelloniWASTE MANAGEMENT

2

Thomé-Kozmiensky und Pelloni

Karl J. Thomé-Kozmiensky

Volume 3 Recycling and Recovery

WASTE MANAGEMENT

Stephanie Thiel

WASTE MANAGEMENTThomé-Kozmiensky und Thiel

3

2

1

, Thiel

5

WASTE MANAGEMENT Volume 2

KARL J. THOMÉ-KOZMIENSKY STEPHANIE THIEL HRSG.

Copyright © 2011 TK Verlag Karl Thomé-Kozmiensky Alle Rechte vorbehalten.

Das Einspeisen der Daten in Netzwerke ist untersagt.

Rüdiger Margraf

Waste Incineration

Figure 7:

Rough scheme dry hydration CaO Dosing balanceH2O

Dry hydrator CaO

CaO Silo

Ca(OH)2 Ca(OH)2

Silo towards lime dosing TIC

Several plants in Germany have been provided with this technology.

Figure 8 shows a plant, realised with a dry hydrator for a Ca(OH)2 production capacity of approximately 3 t/h.

Figure 8: RDF incineration plant EEW Premnitz / Germany As alternative there is the possibility to install the dry hydrator close to the additive

2 can now be injected directly into the reactor without temporary storage in a silo.

Figure 9 shows such a dry hydrator as well as the corresponding WtE plant.

Verbrennungs-rost Gewebefilter Elektro-filter Sprüh-

trockner Kamin

Dampf-kessel MüllkranAufgabe-trichter

Müll- bunkerVerbrennungs-luftgebläsevorrichtungAufgabe-Platten-wändeTrogkettenfördererEntschlackung/

Ammoniak-Wasser- Eindüsung

Kessel- entaschung

AbgaswäscherDruckerhöhungs-gebläse Adsorbenssilo

Feuerraum Primär-luft

Figure 3:

Waste Management, Volume 1 (ISBN: 978-3-935317-48-1) Published: 2010 Hardcover: 623 pages Language: English, Polish, German Price: 15.00 EUR

7ASTE-ANAGEMENT6OLUME (ISBN: 978-3-935317-69-6) Published: 2011 Hardcover: 866 pages Language: English Price: 50.00 EUR

#$7ASTE-ANAGEMENT6OLUME (ISBN: 978-3-935317-70-2) Language: English, Polish, German

Waste Management, Volume 3 (ISBN: 978-3-935317-83-2) Published: 2012 Hardcover: 744 pages Language: English Price: 50.00 EUR

Waste Management, Volume 4 (ISBN: 978-3-944310-15-2) Published: 2014 Hardcover: 521 pages Language: English Price: 50.00 EUR Waste Management, Volume 5 (ISBN: 978-3-944310-22-0) Published: 2015 Hardcover: 500 pages Language: English Price: 120.00 EUR Publisher: Waste Management Vol. 1 + : +ARL*4HOMÏ+OZMIENSKY,UCIANO0ELLONIsWaste Management, Vol. 3–5: Karl J. Thomé-Kozmiensky, Stephanie Thiel

MBT and SRF

The Market for Mechanical Biological Waste Treatment Plants in Europe

Mark Döing

1. Object of investigation ...344

2. Differentiation ...344

3. Functions ...345

4. Technology ...345

5. Legal specifications ...347

6. Development of MBT plants ...348

7. Market factors ...349

8. Current plants ...350

9. Development ...351

10. Outlook...352

Both the number and capacities of mechanical biological treatment plants (MBT plants) have increased significantly in the past years. In late 2015, about 490 MBT plants were active in Europe, reaching a disposal capacity of circa 47 million annual tons. However, despite its steady growth, the MBT market showed volatility. The market development peaked in 2005/2006, with the commissioning of about 80 plants with a capacity of circa 9 million annual tons. In 2015, about 13 new facilities with a capacity of around 2.2 million annual tons went online. The MBT market has also shifted geographically, because the European countries have started implementing the EU Landfill Directive in different years. After MBT plants had mainly been constructed in Southern Europe, Germany and Austria before 2006, investments shifted towards the UK and more recently, towards Eastern Europe. In the coming years, an ambivalent development is expected. Whereas further MBT plants will be constructed in countries still sending large shares of their MSW to landfills, MBT technology will experience increasing pressure in the countries with low landfilling shares.

MBT and SRF

1. Object of investigation

The following information is based on the study The European Market for Mechanical Biological Treatment Plants, which we plan to publish in autumn 2016. Preliminary findings, current as of May 2016, were used for this article. However, the figures may change in the course of further analysis, but probably only to a marginal extent.

2. Differentiation

Mechanical biological treatment plants are (pre)treatment facilities with at least one mechanical treatment process and a possible biological treatment process.

In terms of technology, there are many different types of plants pretreating waste in this way. Some of these plants have names other than MBT plant. Depending on the country or the source, various names are used, including mechanical plant (MP), mechanical physical plant (MPP) or single-stream sorting facility. In this article, such plants will be called MBT plants, even though not all of the facilities are equipped with a biological treatment process.

MBT plants sort and treat mixed waste, first and foremost municipal solid waste (MSW), but also waste with similar features, e.g. from the commercial sector.

Their focus on mixed waste is what differentiates MBT plants the most from sorting plants processing separately collected recyclables, such as plastics, packagings, paper or glass. These sorting plants use a comparatively homogeneous material as their input, whereas MBT plants process very heterogeneous material similar to the input of waste incineration plants or landfill sites.

This specialisation in heterogeneous waste results in major differences when it comes to technology and market. For example, sophisticated MBT plants must be equipped with a significantly more complex sorting and treatment structure than sorting plants for separately collected recyclables.

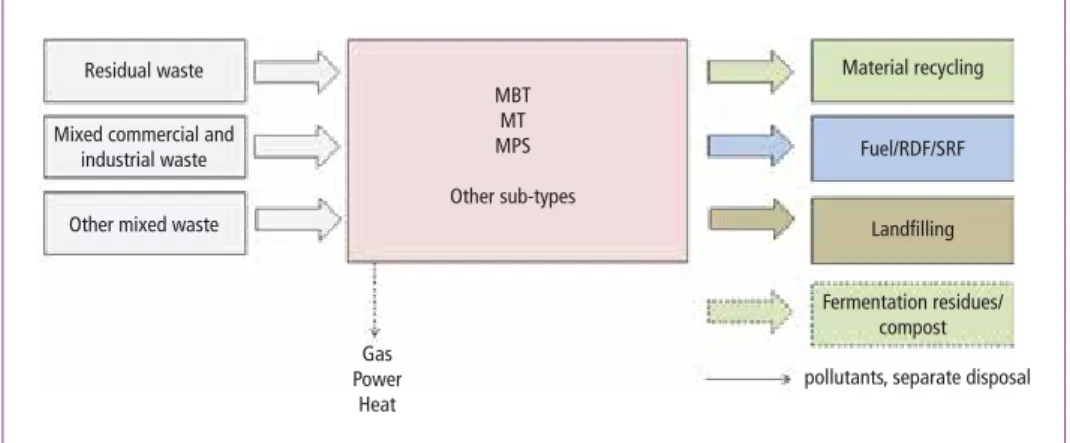

Residual waste

Mixed commercial and industrial waste

Other mixed waste

MBT MT MPS Other sub-types

Gas Power

Heat

pollutants, separate disposal Material recycling

Fuel/RDF/SRF

Landfilling

Fermentation residues/

compost

Figure 1: Overview MBT plant

MBT and SRF

3. Functions

The three most important functions of MBT plants are:

• Material recovery of mixed waste

One of the major ecological targets of MBT is to sort secondary raw materials such as glass, plastics or paper out of the mixed waste fraction, so that they can undergo material recovery. Depending on the applied technology, 2 to 5 percent of the pro- cessed residual waste can be sorted out as recyclables and then be sent to material recovery. At plants with a biological treatment process, separating the organic share and then processing it to fertiliser (compost) are also parts of material recovery.

• Energetic recovery of mixed waste

Preferably, a large share of the mixed waste that cannot be separated any further, either for technical or for economic reasons, should be processed into high-quality refuse-derived fuel (RDF). This share should be as large as possible. Measures of this process include e.g. reducing the moist, removing contaminants or reducing the grain size in the waste.

Plants with a biological treatment process in the form of an AD (anaerobic diges- tion) unit may generate their own energy: gas, electricity and/or heat.

• Pretreatment before sending the waste to landfilling

Waste that can neither undergo material nor energy recovery, is usually landfilled, and typically treated beforehand. Measures of such a process include reducing the waste’s reactivity, e.g. through biological treatment or the removal of contaminants, which would cause long-term pollution in soil, groundwater or air.

Every plant has a different focus. Which function is put an emphasis on, depends on the features of the input material, but also on the specifications the different output materials have to comply with. The latter are in turn mainly determined by economic factors, e.g. the price development for secondary raw materials and RDF or the level of landfill charges.

4. Technology

Mechanical biological waste treatment is not a distinct technology, but rather a com- bination of already existing ones, particularly sorting technology and biological waste treatment.

Each plant has its individual combination of these technologies and process steps, mainly based on the respective function of the facility. There is no standardised design for MBT plants and technical heterogeneity within an MBT plant is considerably higher than in every other type of waste infrastructure.

The design of most MBT plants can roughly be differentiated into the following steps:

delivery/first storage, shredding, sorting, biological treatment, waste air purification and other supporting processes.

MBT and SRF

Figure 2: Decomposing a composite through shredding

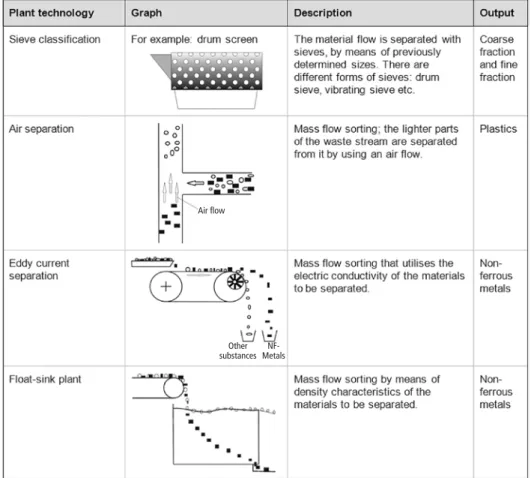

In particular, shredding and sorting processes are repeated for a different number of times. Depending on the input of an MBT plant, sorting processes such as sieve classification, air separation, eddy current separation or float-sink separation may be used. Crushing processes such as shredding or tearing are often done before or after the former. The grain size is not only reduced to facilitate the transportation of the material within the plant. Crushing also decomposes some composites and allows for using the then individualised output in different ways. Incinerating material in a fluidised bed incinerator, for instance, needs grain sizes not exceeding a specific maximum.

Composite Shredding Sorting

Plastic Wood Plastic Wood Sorting residue

Figure 3: Selected technologies for waste separation

Air flow

Other substances NF-

Metals

MBT and SRF

Many MBT plants start biological treatment in a comparatively early phase, meaning before complex mechanical sorting begins. In such plants, almost all of the entire input including organic matters undergoes biological treatment. This process has the advantage that the water content is considerably lower after biological treatment, which drastically facilitates later sorting processes.

Other plants remove the organic fraction from the mixed waste at first and then sort it. This facilitates biological treatment as the material contains fewer impurities. Ad- ditionally, biological treatment does not have to have large capacities, as only a part of the plant’s input undergoes this process. Eventually, the output of this treatment is 100 percent organic and it is easy to market this material as compost.

Almost all plants are currently using (aerobic) composting (rotting) or anaerobic digestion (AD) technologies. Again, a plant’s function significantly determines which technology to apply. Other market factors are important as well, for instance marketing a plant’s output as compost or obtaining subsidies – e.g. feed-in tariffs – for generating electricity in an AD unit.

Waste air purification is mainly based on national emission limits, also within the EU.

Some countries have specific limits for MBT plants; others have not yet introduced such values. MBT plants primarily emit dusts, germs, odours and other gaseous organic substances, such as solvents.

Other supporting processes can include wastewater treatment, drying, temporary storage and commissioning.

5. Legal specifications

Another reason for the heterogeneous MBT plants in Europe is the lacking of a EU-wide obligatory specification, similar to the Waste Incineration Directive for combusting waste.

The only specifications for individual process steps within MBT plants, such as sorting technologies, refer to defining best available technologies (BATs). Such specifications are included in the Reference Document on Best Available Techniques for the Waste Treatments Industries (from 2006). These so-called BREFs are an outcome of the EU’s Sevilla process, under which technical procedures are described for selected industries with relevant emissions. These best available technologies/techniques represent the ones that are currently possible in technical terms and at the same time economically justifiable. They are determined in close collaboration with the respective industry.

The EU-wide defined BATs are not only the basis for planning law, but are also of great importance for civil law, e.g. for insurance costs or who is legally responsible when in the case of accidents.

The current BAT document for the waste industry was published in 2006. It has been under review for several years and a draft from December 2015 was the latest available information by the time this article was written. The successor document can generally be expected to come into force in 2016/2017.

MBT and SRF

However, as many different types of waste and treatments are used, the BAT documents do not contain explicitly concrete specifications. They mainly refer to general process steps, such as inspections and lab analyses. The BAT documents only contain few concrete limit values, contrary to the BAT documents for other industries.

The few existing detailed specifications furthermore refer to individual technologies, e.g. the anaerobic digestion of biological waste. There are no MBT-specific guidelines.

Legal specifications of other segments have a great indirect impact on the operation of MBT plants, e.g. regulations within the waste management industry, such as limit values for landfilling or waste incineration.

6. Development of MBT plants

There are different motivations for constructing an MBT plant, differing by project.

However, historically, three main developments have been the reason that most of the MBT facilities exist today.

• Advancement of household waste composting: Some countries, especially in Sou- thern Europe, traditionally compost large shares of their residual waste to use it as fertilizer. Historically, this type of disposal had not been as problematic as it may sound today, as most of the residual waste was organic material. However, as the composition of residual waste became more complex, e.g. due to increasing shares of plastics or also contaminants, sorting of the waste had to become more complex as well.

This presorting of residual waste then resulted in MBT plants, again particularly in Southern Europe. Some of these still sort out organic material to treat it biologically and then use it as fertilizer.

• Alternative to thermal recovery: Some countries, e.g. Germany and the UK, have considered (and still do) mechanical biological treatment of waste as an explicit al- ternative to waste incineration plants processing untreated waste. In extreme cases, MBT plants were meant to obviate the need for an incineration plant and it was not planned to produce RDF.

This approach was mainly based on implementing the EU Landfill Directive, which in fact obliged the municipalities of some countries to treat their residual waste. As thermal waste recovery, for which established technologies had been available at that time, was (and still is) controversial at many places, responsible actors started looking for alternatives.

• Logistical optimisation: Particular modern concepts consider MBT plants to be a part of the residual waste treatment process chain. In rural areas in particular, MBT plants are constructed in order to minimise transportation needs for residual waste treatment. Pretreating the residual waste in an MBT plant reduces its volume, espe- cially by minimising its water content. At the same time, the waste is optimised for transportation means. In the best case, only parts of the residual waste, e.g. in the form of RDF, have to be transported over longer distances. Furthermore, average capaci- ties and therefore investment costs are smaller/lower in comparison to incineration plants, which is positive especially for smaller municipalities.

MBT and SRF

7. Market factors

The EU Landfill Directive (1999/31/EC) is the most important past and present market factor for the increase of MBT capacities. This directive aims at drastically reducing environmental impacts of landfills. In order to reach this goal, the directive includes both technical specifications for waste landfill sites, but also specifications for the waste going to such sites.

The latter have especially far-reaching consequences. Minimum requirements for the material features of the waste destined for landfilling came into effect as of July 2006, re- ferring e.g. to breathability or gas formation. Furthermore, the amounts of biodegradable MSW going to landfills have to be reduced in three steps by 2016, finally to 35 percent of the 1995 amount.

Specific transitional periods were agreed upon for countries with high MSW landfilling shares, e.g. the UK or Greece and most of the new member states in Central and Eastern Europe, which have joined the EU since 2004. Deadlines will expire in 2020 at the latest in most of the countries and only few states were granted longer periods for fulfilling the targets – for instance Croatia, the youngest member state.

Generally, several strategies may be chosen for reducing the organic fraction of MSW, among them increasing the separate collection of organic waste and subsequently process this biowaste in composting or AD plants. However, in regard to residual waste treatment options are reduced to thermal recovery without pretreatment and mechanical biological treatment – as the only treatment or for pretreating the waste before sending a fraction to further thermal recovery.

The countries have realised in parts very different systems for implementing the EU Landfill Directive. However, the MBT market is not only influenced by waste landfilling specifications, but also by waste incineration regulations, which already may be shown with this short list:

• Germany: Landfill ban for untreated MSW, economic preconditions for waste inci- neration plants and MBT plants are similar to a great extent.

• UK: Landfill tax for untreated waste, burdens on waste incineration plants and MBT plants are the same to a large extent, MBT plants benefit in parts from RE policy.

• Poland: Landfill tax on untreated waste, reduced rates for MBT plant output.

• France: Landfill tax for untreated waste, incineration tax and regional upper limits for thermal recovery (policy changed in 2015).

These varying regulations result in very different market factors for the development of MBT capacities in the EU. As a result of these differing policy approaches, France and Poland constructed more MBT plants than waste incineration plants in the past years;

Germany and the UK did it the other way round.

Other European waste legislation also influences the MBT market. The EU Waste Framework Directive, for instance, includes specifications for material recovery of MSW, e.g. for paper and plastics. The EU Industrial Emissions Directive and the standards

MBT and SRF

based on it within the framework of the BATs have impacts as well. However, these effects on the MBT market are considerably weaker than those of the Landfill Directive.

Apart from legal framework conditions, other markets also have impacts on the pro- fitability of MBT plants, first and foremost the development of gate fees for secondary fuels in waste incineration plants, RDF power plants, cement works and coal power plants, which for their part also depend on the price development for fossil fuels, at least to some extent. Prices for secondary raw materials such as plastics also influence the profitability of MBT plants, as they affect the revenues of sorting products from MBT plants.

8. Current plants

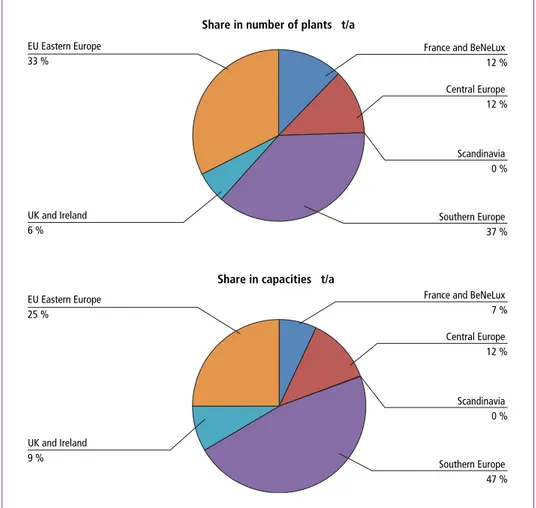

In late 2015, about 490 MBT plants were active in Europe, reaching a disposal capacity of circa 47 million annual tons.

Share in number of plants t/a

Share in capacities t/a

France and BeNeLux 12 % EU Eastern Europe

33 %

Southern Europe 37 % UK and Ireland

6 %

Central Europe 12 %

Scandinavia 0 %

France and BeNeLux 7 %

Southern Europe 47 % Central Europe 12 %

Scandinavia 0 % EU Eastern Europe

25 %

UK and Ireland 9 %

Figure 4: MBT plants in Europe, as of late 2015

MBT and SRF

Most capacities are operational in the 6 Southern European and 10 Eastern European countries. About 50 percent of all plants and capacities are active in Italy and Poland.

In terms of number of plants, France follows with about 50 MBT plants; however, these facilities have a quite low average capacity. In terms of capacities, France ranks fifth, after Germany and the UK.

9. Development

MBT capacities in Europe have increased steadily in the past 15 years. An estimated 12 to 13 million annual tons of capacity were operational around 2000, a very large share of which in Southern Europe, especially in Italy.

From 2000 onwards, ever more new plants were commissioned as the countries started implementing the EU Landfill Directive. Apart from Italy, the markets in Germany and Austria developed in a particularly dynamic way. An increasing number of MBT plants were also built in Poland. This development peaked in 2005/2006, as a direct result of the Landfill Directive that Germany and Austria implemented in the form of landfill bans.

In these years, an estimated 80 plants with a capacity of about 9 million annual tons were commissioned in Europe.

However, this was not only a peak, but also a turning point. Technical and economic problems of many newly commissioned MBT plants caused a serious image problem, especially in Germany, the largest European market. The peak of this development was the shutdown of the facilities in Buchen and Heilbronn, after they had only been operational for a few months each. No new MBT plant has been commissioned in Germany since 2006.

By contrast, the MBT market boomed, in particular due to the implementation of the EU Landfill Directive, in countries such as the UK and France. Furthermore, many MBT plants were built in Eastern Europe, especially in Poland, as low investment costs in rural areas pushed the development of many facilities. In Poland, waste incineration plants should only be constructed in disposal areas with at least 300,000 inhabitants, whereas MBT is the preferred technology for treating residual waste in all other disposal areas.

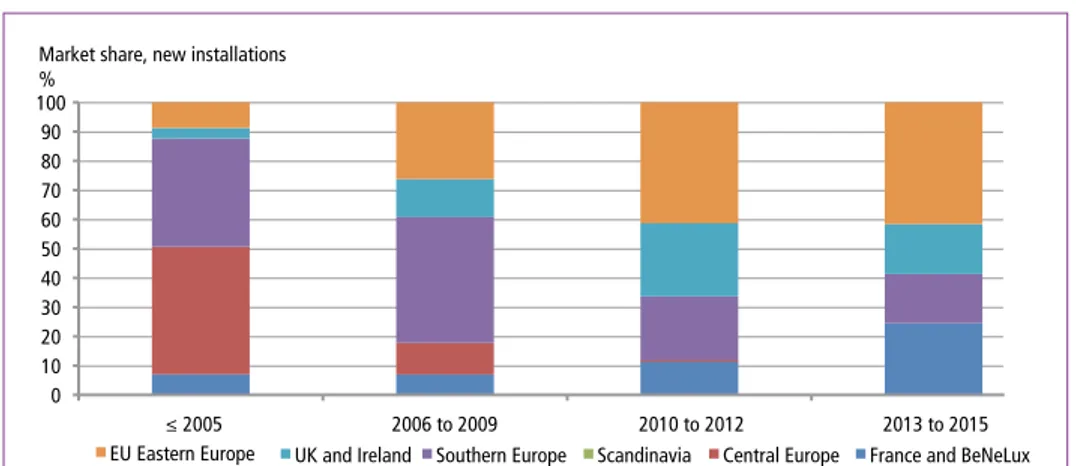

0 10 20 30 40 50 60 70 80 90 100

≤ 2005 2006 to 2009 2010 to 2012 2013 to 2015 EU Eastern Europe UK and Ireland Southern Europe Scandinavia Central Europe France and BeNeLux Market share, new installations

%

Figure 5: Geographical shift of the European MBT market

MBT and SRF

As the countries started implementing the EU Landfill Directive in different years, the MBT market shifted as well. Earlier than 2006, MBT plants had especially been construc- ted in Southern Europe, Germany and Austria. After that, investments shifted towards the UK and then towards Eastern Europe. For the Eastern European market, not only the large rural areas and the low investments costs are important factors, but also EU subsidisation policy, which also prefers MBT plants to be constructed in rural areas.

In 2015, about 13 new plants with a capacity of about 2.2 million annual tons were commissioned. Over 50 percent of the capacities were located in Eastern European countries.

10. Outlook

As in the past, the MBT market will remain ambivalent and the developments will vary significantly by country. However, there are two generally important developments:

• Countries with a still high share of municipal waste going to landfills will con- struct further MBT plants. This holds especially true for Eastern Europe. A further development can also be expected for some Southern European countries, e.g. for Portugal and Spain, even though this will be limited in its extent.

• MBT technology will be pressurised further in countries with low landfilling shares.

This pressure is on the one hand a result of a stronger focus on material recovery and organic treatment. On the other, discussions on the features and the disposal of the landfilling fraction of MBT plants become increasingly critical, which may worsen framework conditions for this technology.

The situation gets especially difficult in Germany and France. The former introduced a nationwide obligatory separated household collection of organic waste in 2015, which has also resulted in decreasing organic shares in residual waste. This puts the biological treatment process of some MBT plants into question, and some of them have already been shut down or rededicated for treating separately collected organic waste. De- creasing residual waste amounts furthermore toughens the competition between MBT plants and waste incineration plants, whose operational costs are frequently much lower. In the years to come, the closure of further MBT plants may be expected due to new awarding of municipal residual waste volumes.

In 2015, policies also changed in France, where the development of MBT capacities had been subsidised for years. Instead of MBT plants, the support should now ever more focus on separate collections, material recovery and the increase of organic treatment.

At the same time, sorting residues from MBT plants should be increasingly used in the form of RDF, which is planned to be supported as well. The new government in Poland has postponed a planned law that provided for standards for MBT plant outputs. Al- together, however, thermal recovery of MBT outputs will be one of the most attractive market segments in many European countries in the years to come.

MBT and SRF

These two differing development trends also become manifest in the EU’s Circular Eco- nomy Package that should define the targets of European waste legislation for the period after 2020. This should include a further reduction of MSW landfilling to 10 percent in 2030, which tends to support the construction of residual waste treatment capacities, and also of MBT pants. At the same time, material recovery of MSW should increase to 65 percent, which will result in declining residual waste treatment, particularly in the more advanced waste management systems.

Dorfstraße 51

D-16816 Nietwerder-Neuruppin

4ELs&AX E-Mail: tkverlag@vivis.de

www.

.de

TK Verlag Karl Thomé-Kozmiensky

Wir widmen uns aktuellen verfahrens- und anlagentechnischen sowie politischen, rechtlichen und wirtschaftlichen Themen, soweit sie die Abfall- und Kreislaufwirtschaft, die Energie- und Rohstoffwirtschaft und den Immissionsschutz betreffen.

Unsere Aufgabe sehen wir in der Kommunikation zwischen Politik, Verwaltung, Wirtschaft, Technik und Wissenschaft.

Zu wichtigen Themen veranstalten wir Konferenzen und Congresse – dazu geben wir Bücher heraus.

Stets sind wir auf der Suche nach interessanten Referenten, aktuellen Themen und spannenden Projekten um unser Angebot weiterzuentwickeln. Gern lassen wir uns von neuen Ideen inspirieren und diskutieren deren Realisierbarkeit.

Der TK Verlag gibt seit dreißig Jahren Fachbücher zu zahlreichen Themen des technischen Umweltschutzes heraus:

Unsere Konferenzen im Überblick:

s"ERLINER!BFALLWIRTSCHAFTSUND%NERGIEKONFERENZ s"ERLINER2ECYCLINGUND2OHSTOFFKONFERENZ s"ERLINER+ONFERENZ

Mineralische Nebenprodukte und Abfälle s)22#n7ASTETO%NERGY

s"ERLINER)MMISSIONSSCHUTZKONFERENZ s4HERMISCHE!BFALLBEHANDLUNGUNDENERGETISCHE6ERWERTUNG

s-ECHANISCHBIOLOGISCHE!BFALLBEHANDLUNG und Ersatzbrennstoffe

s"IOLOGISCHE!BFALLBEHANDLUNG s2ECYCLINGUND2OHSTOFFE s6ERPACKUNGEN

)NSGESAMTSINDBISLANGBEIUNSETWAZWEITAUSEND&ACHBEITRË- ge erschienen, die in ihrer Gesamtheit einen guten Überblick über technische, wirtschaftliche, rechtliche und politische Entwicklungen geben. Seit Kurzem stellen wir Ihnen die

&ACHBEITRËGE KOSTENLOS AUF UNSERER )NTERNETSEITE ZUR Verfügung.

Thomé-Kozmiensky + Goldmann Recycling und Rohstoffe Band 7

Thomé-Kozmiensky und Beckmann Energie aus Abfall 11 Thomé-Kozmiensky und Beckmann Energie aus Abfall 11

Thomé-Kozmiensky + Goldmann Recycling und Rohstoffe Band 5 Karl J. Thomé-Kozmiensky und Andrea VERSTEYLs0LANUNGUND5MWELTrecht 6Karl J. Thomé-Kozmiensky und Andrea VERSTEYLs0LANUNGUND5MWELTVERSTEYLs0LANUNGUND5MWELTVrecht 6

)--)33)/.33#(54:

2

Thomé-Kozmiensky Dombert,

Versteyl, Rota

rd, Appel

4K. J. Thomé-Kozmiensky & S. Thiel WASTE MANAGEMENT 4

K. J. Thomé-Kozmiensky & S. Thiel WASTE MANAGEMENT

Karl J. Thomé-Kozmiensky 3TRATEGIE0LANUNG5MWELTR ECHT

Besuchen Sie uns unter

Thomé-Kozmiensky + Goldmann Recycling und Rohstoffe Band 4

Bibliografische Information der Deutschen Nationalbibliothek Die Deutsche Nationalbibliothek verzeichnet diese Publikation in der Deutschen Nationalbibliografie; detaillierte bibliografische Daten sind im Internet über http://dnb.dnb.de abrufbar

Thomé-Kozmiensky, K. J.; Thiel, S. (Eds.): Waste Management, Volume 6 – Waste-to-Energy –

ISBN 978-3-944310-29-9 TK Verlag Karl Thomé-Kozmiensky

Copyright: Professor Dr.-Ing. habil. Dr. h. c. Karl J. Thomé-Kozmiensky All rights reserved

Publisher: TK Verlag Karl Thomé-Kozmiensky • Neuruppin 2016

Editorial office: Professor Dr.-Ing. habil. Dr. h. c. Karl J. Thomé-Kozmiensky,

Dr.-Ing. Stephanie Thiel, M. Sc. Elisabeth Thomé-Kozmiensky, Janin Burbott-Seidel und Claudia Naumann-Deppe

Layout: Sandra Peters, Anne Kuhlo, Janin Burbott-Seidel, Claudia Naumann-Deppe, Ginette Teske, Gabi Spiegel und Cordula Müller

Printing: Universal Medien GmbH, Munich

This work is protected by copyright. The rights founded by this, particularly those of translation, reprinting, lecturing, extraction of illustrations and tables, broadcasting, micro- filming or reproduction by other means and storing in a retrieval system, remain reserved, even for exploitation only of excerpts. Reproduction of this work or of part of this work, also in individual cases, is only permissible within the limits of the legal provisions of the copyright law of the Federal Republic of Germany from 9 September 1965 in the currently valid revision. There is a fundamental duty to pay for this. Infringements are subject to the penal provisions of the copyright law.

The repeating of commonly used names, trade names, goods descriptions etc. in this work does not permit, even without specific mention, the assumption that such names are to be considered free under the terms of the law concerning goods descriptions and trade mark protection and can thus be used by anyone.

Should reference be made in this work, directly or indirectly, to laws, regulations or guide- lines, e.g. DIN, VDI, VDE, VGB, or these are quoted from, then the publisher cannot ac- cept any guarantee for correctness, completeness or currency. It is recommended to refer to the complete regulations or guidelines in their currently valid versions if required for ones own work.