289 Engineering Model Development with Artificial Intelligence

Waste Incineration

Engineering Model Development with Artificial Intelligence

Martin Horeni and Michael Wechner

1. Artificial intelligence – Neuronal networks ...289

2. Evaluation of process parameters with neuronal networks ...290

3. Properties of engineering neuronal networks ...291

4. Examples ...293

4.1. Substitute engineering model Steam turbine for power production forecast ...294

4.2. Substitute engineering model Heat exchanger for performance forecast ...297

4.3. Results ...298

4.4. Other applications ...300

5. Development and implementation of neuronal networks ...300

6. Conclusion ...301

1. Artificial intelligence – Neuronal networks

Very different algorithms and software applications are nowadays summarised as Arti- ficial Intelligence (AI). This includes concepts from standard, linear software code with loops and if-then-decision rules to very complex applications related to auto encoders, deep learning and so on. Common AI definitions comprise either technical aspects in the first place like usage of mechanical decision trees or philosophic aspects like the capability of a machine to be self-consciously.

From an engineering point of view an artificial intelligence has the characteristic of being able to learn technical relationships. As this is the main feature of neuronal networks we simplify in this paper

Artificial Intelligence = Neuronal Networks (and its implementation).

Implementation means the usage of AI algorithms within another software tool, e.g.

for process data analysis. To mention the implementation is important because im- plementation requires much more effort than the neuronal network coding itself. The implementation factor, measured in lines of code, is in a range of 1:1,000 to 1:10,000

Martin Horeni, Michael Wechner

290

Waste Incineration

and more, depending on the usability of the overall software solution. Very often public neuronal network libraries get used instead of coding from scratch. In this case AI (soft- ware) engineering means implementing these libraries in the actual engineering task.

Often it is unclear what artificial intelligence or said neuronal networks can be used for which engineering tasks (and to be more precise: which technical relations should be trained), besides the well-known applications of picture, text or voice recognition. The only common understanding is that AI shall make something possible one could not do before. One very interesting AI usage for process engineering tasks is the development of substitute engineering models. Substitute models describe a technical relationship with outer relations learned from real measured values to substitute a mathematical description of its inner relations by formulas.

2. Evaluation of process parameters with neuronal networks

In engineering neuronal networks are used for recognitionof patterns within values or value constellations. Compared to other evaluation methods it is special that de- pendencies between these values exist but for some reason they are unknown. The unknown values are at least known from the past (measured, already determined) and get reproduced according to the new input values by the learned relationships.

Thus neuronal networks respectively artificial intelligence algorithms are together with simple regression methods in an overview of different methods for process data evaluation (Figure 1).

The figure illustrates that neuronal networks do not replace the conventional methods like energy and mass balancing or the application of phenomenological models for heat transfer calculation in heat exchangers, but can complement them in a smart way. It is interesting that neuronal networks with continuous output values (in comparison to

Figure 1:

Classification of process para- meters

dependencies ...

on site DCS,

data acquisition system (DAS)

office software engineering software process parameters

calculated values no

dependencies measured

values

known

because ... not know if ... then ...

measure- ments on site

balances, chemical equilibriums,

pheno- menological

models simple

calculations, KPls

regression methods, artificial neuronal networks

off site

291 Engineering Model Development with Artificial Intelligence

Waste Incineration

discrete output values, see next chapter) are by nature regression methods. Someone creating a trend line within a x-y-chart in a spreadsheet develops a model based on already existing values. As the software searches iterative for a function that provides y-values as close as much to the given y-values this already represents a learning behaviour and therefore some kind of artificial intelligence. The big difference to neu- ronal networks is that such networks are made for not only two dimensions but many dimensions. The neuronal network disadvantage of course is the imagination – it is not easy to visualize more than three dimensions in a reasonable manner.

3. Properties of engineering neuronal networks

In energy conversion or material treatment processes neuronal networks are used to gain mathematical formulas describing statistical relationships between measured values.

In general, there are two fields of using neuronal networks in engineering:

A) Development of substitute engineering models and B) Process status analysis.

Process status analysis with neuronal networks means to characterize the way differ- ent measurements for different process conditions act together and to identify those measurements where this changes over time. To develop substitute engineering models means to model systems without taking fundamental, scientific relationships between input and output values into account. Reason to do so can be:

• the mathematical relationship is unknown (too many parallel equations, unclear equilibrium states, unknown transient terms) or

• the mathematical relationship is known, but models based on the scientific funda- mentals cannot be validated with the measured values (= the theory does not match the practice).

Of course, it is also possible to use the results of substitute engineering models for common process status analysis where often the focus is on one single, maybe critical process parameter.

By far the most frequent application of neuronal networks – at least in public aware- ness – is the recognition of already existing common patterns (pictures, characters, sounds, etc.). In comparison to this, the sought engineering patterns respectively the values causing such patterns are always new and therefore related models not able to be transferred.

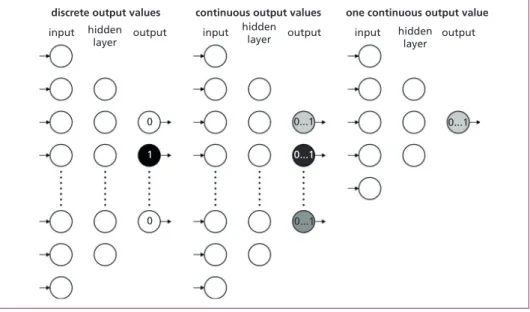

For differentiation it is important to understand that recognition of already existing patterns neuronal networks with discrete output values are used. Reasonable output values are either close to 0 (sometimes also -1 instead of 0) or close to 1. An output value somewhere between 0 and 1 means no pattern was found. For engineering usu- ally neuronal networks with continuous output values are used with reasonable output values between 0 and 1 (Figure 2).

Martin Horeni, Michael Wechner

292

Waste Incineration

Figure 2: Different neuronal networks depending on type and number of their output values, exemplary with three layers

These and other differences are listed in Table 1.

Table 1: Main differences between neuronal networks with discrete and with continuous output values

Output values discrete continuous *

Field of application recognition of common patterns recognition of individual patterns Affected patterns pictures, audio signals, symbols, videos, etc. process states, single process values Data sources often public, similar or identical data process/plant related

for different implementations

Number of > 1,000 substitute engineering models: << 100,

input channels (ca.) process status analysis: varying

according to system size

Number of = number of patterns to be recognized substitute models: 1, process analysis:

output channels (number of pictures, number of music titles, etc.) varying according to system size

Training data many data available, only limited available,

sometimes also expendable (rotation of pictures), training data = process data/measured affected patterns sometimes to be added values, cannot be generated arbitrarily

* related to engineering applications

For engineering tasks it is characteristic that neuronal networks require significantly less data (number of channels times number of data per channel) than for common pattern recognition, but are more demanding in terms of describing the technical problem and what the neuronal network shall be used for.

Other characteristics when using neuronal networks for engineering are:

input hidden

layer output input hidden

layer output input hidden layer output

0

0 1

0...1 0...1

0...1 0...1

discrete output values continuous output values one continuous output value

293 Engineering Model Development with Artificial Intelligence

Waste Incineration

Neuronal network type It is often a question how deep a neuronal network must be. This depth represents the number of used layers. All examples discussed in this paper are based on neuronal networks with only one hidden layer resulting in a network consisting of three layers in total (input layer, hidden layer, output layer).

When searching for critical measurement deviations convolutional neural networks can be used. They allow putting a measurement and its variation in context to other measurements. Doing so it is possible to evaluate deviations of the given variations over time. Convolutional neuronal networks comprise at least five layers.

Often neuronal networks with internal feedback loops are described. These feedbacks allow taking the values history into account. For the examples described here feed- back-networks are not interesting.

Activation function Basis for appropriate neuronal network learning is the so called neurons activation.

The neurons activation determines the intensity of forwarding values within a neuron.

For this mostly a sigmoid function is used. As already mentioned reasonable values for universal pattern recognition are either 0 (sometimes -1) or 1. Output 1 means the output channel(s) related pattern was recognized, output 0 means this is not the case. For engineering applications all output values between 0 and 1 are reasonable.

The distribution of these continuous output values depend on the value normalization done before. In context with the sigmoid function this means, maxima for normaliza- tion must be rather high because otherwise they can hardly be reached caused by the asymptotic function profile.

Often it is said, that neuronal networks are not able to recognize patterns they are not trained to recognize. This is correct for discrete output values – neuronal networks with continuous output values are not only able to interpolate but also to extrapolate within a limited range.

Resolution Power plants run usually anytime at full load and only sometimes at partial load. This means many similar full load values exist but only little partial load values. Training of neuronal networks in such cases is irregular, because more frequent value sets dominate the weights inside the neuronal net compared to rare once. But the model must provide also for partial load operation (and maybe particularly then) correct results. To avoid this it makes sense to use a resolution where a) the input values are discretized and b) similar combinations of discrete values are excluded from training. The training then is done only with even unequal values.

4. Examples

Starting from the basic principle of neuronal networks – mathematical description of statistical relationships between measured values – there are many possible en- gineering applications. These are of course no design tasks as neuronal networks

Martin Horeni, Michael Wechner

294

Waste Incineration

(and AI in general) is about learning from the past. The design of process appa- ratuses, machinery and so on will remain classic engineering, based on science fundamentals and individual experience. As mentioned above neuronal networks are useful for A) development of substitute engineering models, independent from inner relationships between the input and output values and B) to analyse process and operation status.

The two following examples for A) substitute models were developed in five steps:

1) Development of a process engineering model (PE model), with all required for- mulas including the fluid properties based on science fundamentals,

2) Variation of model input values within a given range and calculation of the un- known values (= one output channel),

3) Development of an artificial neuronal network (ANN) based on all datasets, each comprising the input values and the calculated unknown value,

4) Running the neuronal network with all input values and calculation of the related unknown value with the neuronal network for each dataset,

5) Optimisation of the network (number of neurons in the hidden layer, chosen minima and maxima, number of training epochs, etc.), in order to achieve a maximum correlation between both calculation results.

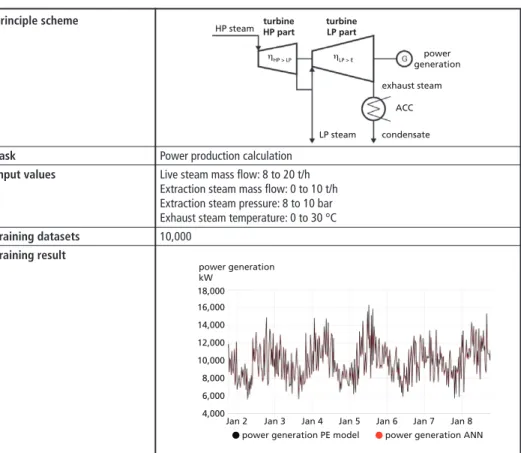

4.1. Substitute engineering model Steam turbine for power production forecast

Main target when forecasting the plant power production is to estimate the energy output for the next days/weeks/months according to time and as accurate as possible.

Main influencing factors on power production in a Waste-to-Energy plant are the live steam production depending on the throughput and if available the supply of process steam and district heating. The heat distribution and – if the plant is equipped with a condensing steam turbine – the power production strongly depends on exhaust steam pressure and therefore on ambient temperature. Furthermore, the day of the week and the daytime have a strong influence.

Other aspects to consider are heat storage systems, backup/secondary steam boilers, load depending steam lines at different pressure levels and so on. Sometimes it is not possible to model all subsystems for every operational state in a satisfying manner.

Then it is worth to consider the usage of a neuronal network for single subsystems.

For the extraction condensing turbine shown here a power production model was developed based on the main influencing parameters. To train the neuronal network the power production was calculated based on given isentropic efficiency ratios. The

neuronal network of course does not know these ratios.

LUEHR FILTER GmbH

Enzer Straße 26

31655 Stadthagen / Germany

The BREF revision will present challenging emission limit values. However, our experience will help you to find the optimised solution for all different fuels such as Waste, RDF, Biomass or Sewage Sludge.

We guarantee

reliable performance within the specified emission limits

high plant availability at low capital and operating costs

flexible system design modified to the specific application

Phone: +49 5721 708-0 Fax: +49 5721 708-214

E-Mail: project@luehr-filter.com Homepage: www.luehr-filter.com

YOUR COMPETENT AND RELIABLE

PARTNER FOR AIR POLLUTION CONTROL

LUEHR FILTER GmbH Enzer Straße 26

31655 Stadthagen / Germany

The BREF revision will present challenging emission limit values. However, our experience will help you to find the optimised solution for all different fuels such as Waste, RDF, Biomass or Sewage Sludge.

We guarantee

reliable performance within the specified emission limits

high plant availability at low capital and operating costs

flexible system design modified to the specific application

Phone: +49 5721 708-0 Fax: +49 5721 708-214

E-Mail: project@luehr-filter.com Homepage: www.luehr-filter.com

YOUR COMPETENT AND RELIABLE

PARTNER FOR AIR POLLUTION CONTROL

Für Wirtschaft und Politik ist ein nachhaltiger Umgang mit Abfall, Rohstoffen und Energie eine Frage der Zukunftssicherung. Umwelttechnisches Know-how und Informationen über grundle- gende Entwicklungen sind für den Erfolg entscheidend. Mit der Fachzeitschrift “ReSource – Abfall, Rohstoff, Energie“ sind Sie bestens über nachhaltiges Wirtschaften informiert.

Neben aktuellen Forschungsergebnissen stellt die Fachzeitschrift praxisrelevante Konzepte und Verfahren zur Vermeidung und Verringerung von Umweltbelastungen vor. Verfahren der kon- ventionellen Abfallbehandlung und -entsorgung wie Verbrennung sowie Recycling, Kompos- tierung, Vergärung und Deponierung werden auf ihre Effektivität und Umsetzbarkeit geprüft.

Experten aus dem In- und Ausland diskutieren Erfordernisse und Beispiele für eine zeitgemäße Rohstoffwirtschaft.

Gerne schicken wir Ihnen ein Ansichtsexemplar: RHOMBOS-VERLAG, Kurfürstenstr.

15/16, 10785 Berlin, Tel. 030.261 94 61, Internet: www.rhombos.de, eMail: verlag@rhombos.de

Abfall • Rohstoff • Energie

ReSource

4

201629. Jahrgang ISSN 1868-9531 4. Quartal 2016 Preis 20,00 EUR A 13158 F

R e S ource

(Früher: MÜLLMAGAZIN · ISSN 0934-3482)Abfall • Rohstoff • Energie Fachzeitschrift für nachhaltiges Wirtschaften

RHOMBOS HERAUSGEBER Dipl.-Pol. Bernhard Reiser

REDAKTION Professor Dr.-Ing. Dr. h. c.

Karl J. Thomé-Kozmiensky † Dr.-Ing. Stephanie Thiel Dipl.-Pol. Bernhard Reiser

REDAKTIONSBEIRAT Professor Dr.-Ing. Michael Beckmann Professor Dr. rer. nat. Matthias Finkbeiner Professor Dr.-Ing. Daniel Goldmann Professor Dr.-Ing. Karl E. Lorber Dipl.-Ing. Johannes J. E. Martin Dipl.-Chem.-Ing. Luciano Pelloni Dipl.-Ing. Christian Tebert Professor Dr. Andrea Versteyl

Felix Müller, Jan Kosmol, Hermann Keßler, Michael Angrick und Bettina Rechenberg

Materialflussindikatoren allein liefern keine hinreichende Orientierung für Strategien zur Ressourcenschonung Uwe Lahl

Ein Regulierungsvorschlag zeigt Ansätze, wie die Treibhausgas- Emissionen aus dem Verkehrssektor bis 2050 drastisch reduziert werden können

Thomas Krampitz, Holger Lieberwirth und Michael Stegelmann Die Berücksichtigung des Recyclings im Life Cycle Assessment der Fahrzeugindustrie ermöglicht Produktentwicklern frühzeitige Aussagen zur Ressourceneffizienz von Produkt und Prozess Roland Pomberger und Renato Sarc

Experten aus Forschung und Praxis haben für Österreich den Beitrag der Abfallwirtschaft zur Ressourcenschonung und Ressourceneffizienz untersucht

Wolfgang Rommel, Siegfried Kreibe und Markus Hertel In erster Linie bestimmen Materialmenge und deren Marktwert den Stellenwert und die Limitierungen des Recyclings von Technologierohstoffen

Jan Schlecht, Jan Henning Seelig und Torsten Zeller Die möglichen Auswirkungen eines Pfandsystems für Elektro- und Elektronikkleingeräte müssen noch genauer untersucht werden

Fotos: pixelio.de

Jahresabonnement (4 Ausgaben): 62 Euro (incl. MwSt. und Versand) 30. Jahrgang 2017

297 Engineering Model Development with Artificial Intelligence

Waste Incineration

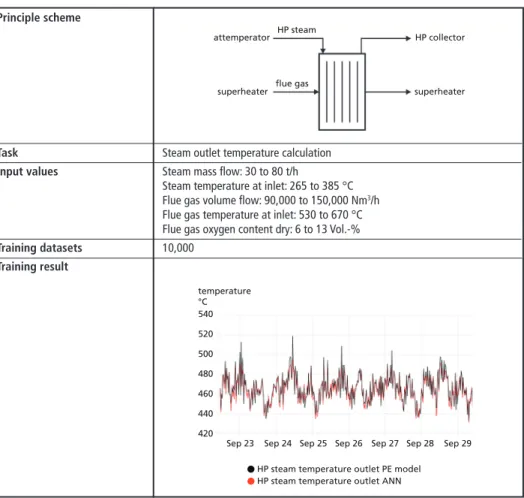

4.2. Substitute engineering model Heat exchanger for performance forecast

The heat transferred within a heat exchanger depends on many factors. These are on the one hand geometric constructive parameters like arrangement, total surface, heat exchanger type and heat surface dimensions and on the other hand the fluid properties of all media flowing through the heat exchanger. In power plant boilers operated with solid fuels another important factor is the fouling. Therefore, correct boiler design is a demanding task that requires sound know how and a lot of experience. This is the same for re-engineering/modelling of an already running boiler. Is the task to develop a model to determine the performance of a heat exchanger under different process conditions (for example to clean the heat exchanger surfaces dependent on fouling level) or to validate the former boiler design (for example to improve a design algorithm) neuronal networks may be an option. In the example of a steam genera- tor heat exchanger shown here a neuronal network was developed to determine the steam temperature at heat exchanger outlet. The neuronal network does not know the geometry of the heat exchanger.

Table 2: Fact sheet neuronal network Steam turbine Principle scheme

Task Power production calculation

Input values Live steam mass flow: 8 to 20 t/h Extraction steam mass flow: 0 to 10 t/h Extraction steam pressure: 8 to 10 bar Exhaust steam temperature: 0 to 30 °C Training datasets 10,000

Training result

HP steam turbine HP part

turbine LP part

power generation exhaust steam

ACC condensate LP steam

ηHP > LP ηLP > E

18,000 16,000 14,000 12,000 10,000 8,000 6,000 4,000 power generation kW

Jan 2 Jan 3 Jan 4 Jan 5 Jan 6 Jan 7 Jan 8 power generation PE model power generation ANN

Martin Horeni, Michael Wechner

298

Waste Incineration

4.3. Results

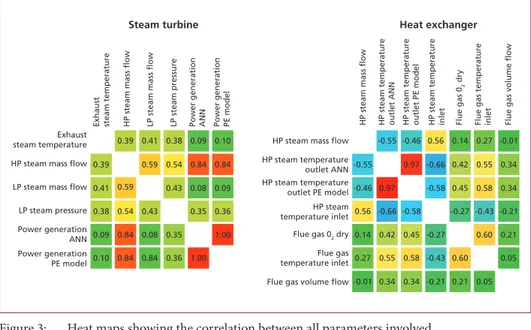

Though all input values got varied in a wide range in both examples the unknown parameters power production and steam outlet temperature almost equal process engineering model and neuronal network. The neuronal networks provide very good results and it is obvious that the result quality depends rather on the measured values than on the modelling approach itself. Figure 3 illustrates the linear correla- tions between all related values. The […] ANN columns show the correlation with the unknown parameter. For the steam turbine the correlation of power production is higher with R=1.0, because the live steam mass flow clearly dominates the power production (strong single correlation with R=0.84). For the heat exchanger the steam temperature correlation R=0.97 is slightly smaller caused by the smaller maximum impact of single input parameters.

Figure 4 illustrates the unknown parameter x-y distribution over the total value range.

Table 3: Factsheet neuronal network Heat exchanger Principle scheme

Task Steam outlet temperature calculation Input values Steam mass flow: 30 to 80 t/h

Steam temperature at inlet: 265 to 385 °C Flue gas volume flow: 90,000 to 150,000 Nm3/h Flue gas temperature at inlet: 530 to 670 °C Flue gas oxygen content dry: 6 to 13 Vol.-%

Training datasets 10,000 Training result

HP steam

HP collector

superheater attemperator

flue gas superheater

540 520 500 480 460 440 420 temperature

°C

Sep 23 Sep 24 Sep 25 Sep 26 Sep 27 Sep 28 Sep 29 HP steam temperature outlet PE model HP steam temperature outlet ANN

299 Engineering Model Development with Artificial Intelligence

Waste Incineration

Steam turbine Heat exchanger

HP steam mass flow HP steam temperature outlet ANN HP steam temperature outlet PE model HP steam temperature inlet Flue gas 02 dry Flue gas temperature inlet Flue gas volume flow HP steam mass flow

HP steam temperature outlet ANN HP steam temperature outlet PE model HP steam temperature inlet Flue gas 02 dry Flue gas temperature inlet Flue gas volume flow

-0.55 -0.55

-0.46 0.56 0.14 0.27 -0.01 0.97 -0.66 0.42 0.55 0.34 -0.46 0.97 -0.58 0.45 0.58 0.34 0.56 -0.66 -0.58 -0.27 -0.43 -0.21 0.14 0.42 0.45 -0.27 0.60 0.21 0.27 0.55 0.58 -0.43 0.60 0.05 -0.01 0.34 0.34 -0.21 0.21 0.05 Exhaust

steam temperature HP steam mass flow LP steam mass flow LP steam pressure Power generation ANN Power generation PE model

Exhaust steam temperature HP steam mass flow LP steam mass flow LP steam pressure Power generation ANN Power generation PE model 0.39 0.41 0.38 0.09 0.10 0.59 0.54 0.84 0.84 0.43 0.08 0.09 0.35 0.36 1.00 1.00 0.84 0.84 0.84 0.08 0.09 0.10 0.38 0.41 0.39

0.43 0.35 0.36 0.59 0.54

Figure 3: Heat maps showing the correlation between all parameters involved

Figure 4:

Correlation of results from pro- cess engineering model (PE model) and from substitute engineering model developed with artificial neuronal networks (ANN)

4,000 4,000 6,000

6,000 8,000

8,000 10,000

10,000 12,000

12,000 14,000

14,000 16,000

16,000 18,000

18,000 power generation

kW

Power generation PE model versus power generation ANN

540 520 500 480 460 440 420 400 temperature ºC

540 520 500 480 460 440 420 400

temperature ºC power generation kW

Steam turbine

HP steam temperature outlet PE model versus HP steam temperature outlet ANN

Heat exchanger

Martin Horeni, Michael Wechner

300

Waste Incineration

4.4. Other applications

Neuronal networks are worth to be considered anytime when common engineering approaches to determine unknown parameters are not applicable but relationships can be found from measured values. In this context other neuronal network applications besides or based on the examples shown above are:

• the localized determination of boiler fouling for focused boiler cleaning

In the shown example Heat exchanger the steam outlet temperature under con- stant boundary conditions will vary only depending on the fouling level. Therefore the variation characterise the fouling of the heat exchanger surface. Because only measured values are used as model input it is easy to determine the fouling per heat exchanger surface.

• the reduction of measured value fluctuations

To prevent short term measured value fluctuations the neuronal network will be trained with the corresponding deviation from an average value. The time range for the average value calculation is chosen in such a way that the fluctuation is just not visible anymore. During plant operation the measured value fluctuation is reduced by the determined deviation.

• to make additional quality criteria available, for example regarding corrosion Given the case process parameters can be allocated to a specific corrosion tendency

somehow measured with a temporary installation (measurement of conductivity, fly ash compositions, etc.) one can reproduce this tendency later with the original process conditions and adjust the plant operation accordingly.

• to make alternative control parameter available

If it is possible to evaluate the correct amount of additives in a flue gas treatment stage (punctual by taking probes and/or additional calculations for certain process conditions) this information can be used for a pre-control of the additive supply before the regular control depending on the clean gas values.

• the detection of incorrect measurements

The neuronal network learns the measured value fluctuation under correct meas- urement conditions. Later it is possible to detect exceptional fluctuations or outliers by comparison of current operation with the original model.

5. Development and implementation of neuronal networks

The highest barrier of a widespread use of neuronal networks for engineering is the missing access to this technology. Only few engineers are in the position to develop neuronal networks easily, optimize them and implement them into higher-level appli- cations (control circuits, forecast models, design tools, etc.). Minimum requirements for software solutions to carry out such tasks are:

301 Engineering Model Development with Artificial Intelligence

Waste Incineration

• easy access to all required process data,

• easy neuronal network configuration: minima/maxima for normalization, number of layers and neurons per layer,

• easy training of the neuronal network: relevant time periods, number of training epochs, number of test data sets, resolution setting for uneven value distributions,

• easy visualisation (trends and correlations), and

• easy export of a developed model in a way one can use it further.

The later three requirements are very important because depending on the task several optimization loops maybe necessary to achieve satisfying correlations.

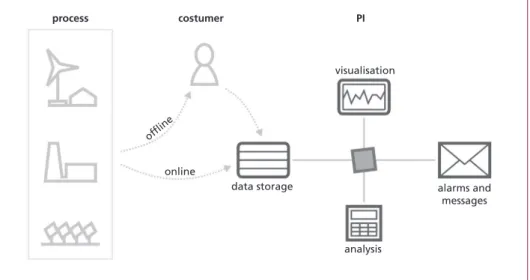

Neuronal networks are based on simple mathematic algebra to connect input values, output values and neurons with each other. No fluid property calculations, iterations or other complex formulas are required. Therefore one can integrate substitute engineering models based on neuronal networks, developed for example with the software PI Pro- cess Intelligence (Figure 5) into higher-level applications like a DCS or an autonomous control or even another spreadsheet for design calculations easily.

offline

visualisation

process costumer PI

analysis

alarms and messages data storage

online

Figure 5: Components of the software solution PI process intelligence for re-engineering, monitoring and data management of technical processes; Analysis includes the AI algorithms

6. Conclusion

The term Artificial intelligence today means almost anytime neuronal networks in the first place. To use neuronal networks for engineering tasks in power stations or process engineering in general is fascinating. There are numerous new possibilities for engineers anytime when dependencies between measured values are being searched,

Martin Horeni, Michael Wechner

302

Waste Incineration

especially when other common engineering methods are not applicable (balancing, models for mass and heat transfer, empirical approaches, equilibrium conditions, etc.) but measured values are already available. Based on neuronal networks it is possible

• to develop substitute engineering models for subsystems, that cannot or only with major effort be modelled – thus allowing more precise forecasts – and

• to carry out process status analysis, not only regarding single measurements but taking a whole set of measurements into account – thus allowing to find irregular- ities earlier.

Furthermore the boiler heat exchanger example shows that new results can be found re- garding mid and long term changes in plant operation conditions (here: boiler fouling).

Neuronal networks are derived from data that come from the process only. Therefore they represent a link between theoretic models and the real world on site. Many engi- neering tasks can be simplified exactly at this point. Especially substitute engineering models based on neuronal networks can make complex things easy and thus are worth to be considered for process re-engineering and optimization tasks.

Contact Person

Dr.-Ing. Martin Horeni solutions-ahead Schweiz GmbH Managing Director

Toblerplatz 5 8044 Zurich SWITZERLAND +41 435451516

martin.horeni@solutions-ahead.ch

A Combination of SNCR Technologies Selective Flue Gas Cooling and TWIN-NO

x®▪

▪

Selective Cooling optimizes flue gas temperatures for the SNCR process at the injection positions. NOx reduction rates are improved and the consumption of reagents is reduced.

The TWIN-NOx® process produces excellent results by combining the advantages of the reagents ammonia water and urea solution.

Combining Selective Cooling and TWIN-NOx®

Mehldau & Steinfath Umwelttechnik GmbH, Alfredstr. 279, 45133 Essen • Tel. +49 201 43783-0 Fax +49 201 43783-33 • zentrale@ms-umwelt.de • www.ms-umwelt.de

Level3 Cooling Water Temp.

Measurement Level 2

Level 1 Mixing and Metering

Module FC

FC Compr . Air

Water Reagent

original SNCR

Extension for future NO limitsX

▪

▪

▪

▪

▪

▪

Low investment costs

Reduced consumption of reagents Easy retrofitting

High availability

Improved NOx reduction rates Safe compliance

with new EU standards

Optical temperature measurement

Vorwort

4

Bibliografische Information der Deutschen Nationalbibliothek Die Deutsche Nationalbibliothek verzeichnet diese Publikation in der Deutschen Nationalbibliografie; detaillierte bibliografische Daten sind im Internet über http://dnb.dnb.de abrufbar

Thiel, S.; Thomé-Kozmiensky, E.; Winter, F.; Juchelková, D. (Eds.):

Waste Management, Volume 9 – Waste-to-Energy –

ISBN 978-3-944310-48-0 Thomé-Kozmiensky Verlag GmbH

Copyright: Elisabeth Thomé-Kozmiensky, M.Sc., Dr.-Ing. Stephanie Thiel All rights reserved

Publisher: Thomé-Kozmiensky Verlag GmbH • Neuruppin 2019 Editorial office: Dr.-Ing. Stephanie Thiel, Elisabeth Thomé-Kozmiensky, M.Sc.

Layout: Claudia Naumann-Deppe, Janin Burbott-Seidel, Sarah Pietsch, Ginette Teske, Roland Richter, Cordula Müller, Gabi Spiegel Printing: Universal Medien GmbH, Munich

This work is protected by copyright. The rights founded by this, particularly those of translation, reprinting, lecturing, extraction of illustrations and tables, broadcasting, micro- filming or reproduction by other means and storing in a retrieval system, remain reserved, even for exploitation only of excerpts. Reproduction of this work or of part of this work, also in individual cases, is only permissible within the limits of the legal provisions of the copyright law of the Federal Republic of Germany from 9 September 1965 in the currently valid revision. There is a fundamental duty to pay for this. Infringements are subject to the penal provisions of the copyright law.

The repeating of commonly used names, trade names, goods descriptions etc. in this work does not permit, even without specific mention, the assumption that such names are to be considered free under the terms of the law concerning goods descriptions and trade mark protection and can thus be used by anyone.

Should reference be made in this work, directly or indirectly, to laws, regulations or guide- lines, e.g. DIN, VDI, VDE, VGB, or these are quoted from, then the publisher cannot ac- cept any guarantee for correctness, completeness or currency. It is recommended to refer to the complete regulations or guidelines in their currently valid versions if required for ones own work.