Global Footprint and Growing

Oerlikon Coating

Oerlikon Vacuum

Oerlikon Drive Systems

Oerlikon Components Oerlikon

Textile

North America

• Sales

•Customer Support

•Operations ( est. 2009)

Asia

• Sales

• Operations

• Pilot Line

• Technology Center

• Customer Support

& Training

Europe

• Solar HQ

• Operations

• Pilot Line

• Advanced R&D

• Product Development

• Customer Support

& Training

Oerlikon

Solar

Oerlikon

Solar

Intense energy consumption of conventional sources drives CO 2 emission

Energy consumption, particularly power generation, is responsible for CO

2emissions

“Energy production is – by far - the most important driver for emissions of greenhouse gases.”

STERN REVIEW: The Economics of Climate Change

“In 2030, global CO

2emissions will be 70%

more than today … and power generation will account for almost half the increase.”

International Energy Agency: Emissions report

Source: Stern Review “The Economics of Climate Change”; IEA

250 275 300 325 350 375

2.000 3.000 4.000 5.000 6.000 7.000 8.000

1960 1970 1980 1990 2000

CO 2 emissions and concentration in the atmosphere have been rising substantially in the last ~50 years

Source: CO

2concentration: C.D. Keeling, T.P. Whorf et. Al., “Air samples collected at Mauna Loa Observatory Hawaii”;

CO

2emissions: G. Marland, B. Andres, T. Boden, “Global emissions from fossil burning”

CO2 concentration in atmosphere (in ppm)

CO

2emissions from fossil fuels (in M t/year)

CO

2concentration in atmosphere

Carbon emissions from fossil fuels

Pre-industrial CO

2level

CO 2 concentration in atmosphere responsible for global warming and climate change

Upsala Glacier, Arg: Once the biggest in South America, now disappearing at a rate of 200m per year

“According to relevant scientific contributors manmade emissions of carbon dioxide (CO

2) are driving … global climate to unprecedentedly warmer temperatures”

IPCC: Survey of IPCC Climate Experts

“… emissions of carbon dioxide (CO

2), the main gas responsible for climate change, as well as of other 'greenhouse' gases …”

European Commission's Climate Change Campaign

Source: IPCC, European Commission

“According to relevant scientific contributors manmade emissions of carbon dioxide (CO

2) are driving … global climate to unprecedentedly warmer temperatures.”

IPCC: Survey of IPCC Climate Experts

1928

2004

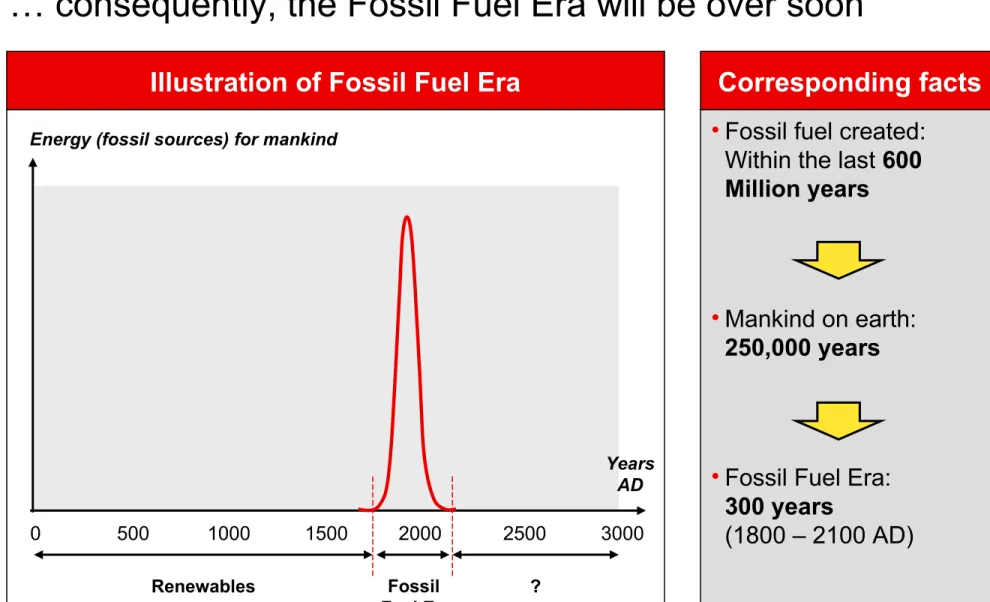

… consequently, the Fossil Fuel Era will be over soon

Energy (fossil sources) for mankind

Years AD

Fossil Fuel Era

Renewables ?

0 500 1000 1500 2000 2500 3000

Illustration of Fossil Fuel Era Corresponding facts

• Fossil fuel created:

Within the last 600 Million years

• Mankind on earth:

250,000 years

• Fossil Fuel Era:

300 years

(1800 – 2100 AD)

Source: Litsearch

Global Energy Supply until 2100

Source: solarwirtschaft.de

Rural (e.g., water pump)

Ubiquitous

consumer products (e.g., clothing)

Space/ high value (e.g., satellites)

Solar PV enables multiple applications

Residential roof-top

Commercial roof- top

BIPV (building integrated PV)

Power plant/ solar park (Ground- mounted systems, mounting may include tracking)

Roof-top or BIPV installations in villages for public and private buildings

Distributed Centralized

Grid-connected Off-grid

Domestic Non-domestic

Source: IEA, Sarasin; Expert Interviews; Oerlikon analysis

Two major technologies within Solar PV: the established bulk crystalline silicon cells and thin film as challenger

Solar modules based on crystalline silicon

Solar modules based on thin film depositions

Source: Industry Reports; Litsearch

Production:

Solar modules produced on the basis of a (crystalline silicon) wafer

Cell functionality, e.g. contacts for electricity extraction, applied onto crystalline wafer

Economic & ecologic characteristics:

Current silicon shortage makes production significantly more expensive

Relatively high (vs. thin film) CO

2emissions during production due to higher raw material intensity

Market share decreasing

Production:

Modules produced via deposition of very thin films onto a glass substrate

Cell functionality, e.g. contacts, also deposited via thin transparent films

Economic & ecologic characteristics:

Lower module production costs and CO

2emissions due to better raw material

efficiency

Competition of several technologies (e.g., Silicon thin fim, CdTe, CIS/ CIGS) additional driver for cost reductions

Market share increasing

0 50 100 150 200 250

2006 2007 2008 2009 2010 2011 2012 2013 2014 2015

GWp

Crystalline silicon Thin film

Oerlikon Solar growth outpaces the photovoltaic market

Ø growth rate 2006-2015

Thin film 74.8%

Crystalline Si 49.4%

Total market 54.0%

(million CHF)

Revenue goals*

>1.000

>700

>300

>140

*Revenues 06-07 pro forma, Solar as stand-alone segment from 08

Installed production capacity / Solar

Primary Production Technologies for Solar Cells

Substrate Cell Issues

Technology

Crystalline Silicon

Thin Films

Cost

Silicon Supply

Large Scale Mfg.

Efficiency

Thin Film Solar Cell Basics

Manufacturing Order

Thin Film Solar Cell Structure Thin Film Solar

Panels

Glass Lamination Back Contact

PV Material Front Contact

Glass

Thin

Films

Laser Scribers

Define Cells

Key process elements needed for scalable Thin Film PV Manufacturing

LPCVD

Deposit Contacts

PECVD

Deposit PV Material

Micromorph Process Technology– up to 50% more Efficiency

The principle of light trapping to deliver high performance

Best Commercial TCO TCO

Oerlikon TCO

a-Si/ µ-Si

a- Si:H

c-Si:H

Amorph

Micromorph Tandem

Visible Near IR

•Integral to Micromorph process

-High transmission in visible and near IR light spectrums

•The goal is to optimize the haze

to better the performance.

Oerlikon is the leading supplier of silicon thin film turnkey solutions

Source: Oerlikon

TCO 1200 – Proprietary TCO Enables Higher Efficiency

TCO TCO

Clean Laser PECVD Laser Laser Assembly

TCO: Transparent Conductive Oxides TCO

TCO back contact

TCO 1200 – Proprietary TCO Enables Higher Efficiency

TCO TCO

Clean Laser PECVD Laser Laser Assembly

The principle of light trapping

Haze 10-25%

T 400-800 93%

T 400-1100 92%

R s <10 Ohm

KAI 1200 – Proven Technology for PV Layers

- Plasma Box

®for single reactor processing

- 40 MHz for increased deposition rates - Parallel processing (20 reactors) and

load lock for high throughput

PECVD

Clean TCO Laser Laser TCO Laser Assembly

amorph micromorph

2 µm 0.3 µm

LSS 1200: Key to Efficiency and Reproducibility

Pattern 3

Laser Laser Laser

Clean TCO PECVD TCO Assembly

The only system qualified for - mass production

- all 3 laser scribing patterns

Back Contact (TCO) a-Si:H

Glass TCO

Pattern 1 Pattern 2

Pattern 3

Pattern 1 Pattern 2

LSS 1200: Key to Efficiency and Reproducibility

Pattern 3

Laser Laser Laser

Clean TCO PECVD TCO Assembly

The only system qualified for - mass production

- all 3 laser scribing patterns

Pattern 1 Pattern 2

It’s All About Lowering Cost per Watt to Reach Grid Parity

$

W p = Total Cost

Throughput x Power

Turnkey Advanced Manufacturing Lines

Micromorph High Efficiency Tandem Solar Cells Oerlikon

Advantage

Cost of Ownership Development to Grid Parity

Thin Film Si Roadmap

Current small

fabs

Equipment cost decrease

Material cost decrease

Other cost decrease

Tact time decrease

Cell efficiency

increase

Economies

of scale 2010 large

fabs

2007

for 20 MWp fabs

< 1.5 $/Wp (<1.12€*/Wp)

2010

for GWp campuses

< 0.7 $/Wp (<0.52€*/Wp)

0 20 40 60 80 100%

*exchange rate 1€ = 1.34$

Achieving Grid Parity

1.5

1.0

0.5

Cost of ownership

Grid Parity

2010 2009

2008

2006 2007

$/Wp

2011 2012

2007 2008 2009 2010

2012

2.00

CapEx per Watt

3.00 4.00

Module efficiency

10%

9%

8%

7%

2010 2009

2008

2006 2007

Amorph

Micromorph Tandem

Next

Generation Thin-Film

2011 2012 11%

13%

12%

Fab nominal capacity

1 0.3 0.12 0.08 0.04

GW/p

2006 2007 2008 2009 2010 2011

c a p a c it y

2012

$/W

3.50

2.50

1.50

GigaFab

(Calculated with an exchange rate of €1.00 =$1.34)