K. Hungerbühler: Risk Analysis of Chemical Processes and Products, SS 2006 1

Risk Analysis of Chemical Processes and

Products

K. Hungerbühler: Risk Analysis of Chemical Processes and Products, SS 2006 2

• introduction and outline

• objectives and content of the course, examination

• case study

• general aspects of “risk”

Introduction

K. Hungerbühler: Risk Analysis of Chemical Processes and Products, SS 2006 3

Industrial development of processes Introduction

Dyestuff production – Ciba Basle, 1916

Pharmaceutical production –

Novartis, 1996

K. Hungerbühler: Risk Analysis of Chemical Processes and Products, SS 2006 4

Industrial development of products Introduction

Insecticide application in the

nineties, example: Pymetrozine®

Insecticide application

in the fifties, example: DDT

K. Hungerbühler: Risk Analysis of Chemical Processes and Products, SS 2006 5

Industrial development of products

DDT Pymetrozine ®

aquatic toxicity LC

50(fish) < 0.002 mg/l > 100 mg/l

persistence (soil) t

1/2> 2 years 3-9 days

bioaccumulation log K

OW> 6 0.2

max. amount applied potato cultures > 2 kg a.i./ha 0.2 kg a.i./ha

Introduction

Comparison of DDT and Pymetrozine ®

DDT Pymetrozine®

K. Hungerbühler: Risk Analysis of Chemical Processes and Products, SS 2006 6

Framework: Integrated development

how ? what ?

Introduction

Chemical product and process development:

objective, effectiveness and efficiency

needs chemical

process

needs chemical

process chemical

product chemical

service

K. Hungerbühler: Risk Analysis of Chemical Processes and Products, SS 2006 7

Framework: Integrated development Introduction

page 3

prote ction

crite ria develo

pmen t goa

ls

K. Hungerbühler: Risk Analysis of Chemical Processes and Products, SS 2006 8

Framework: Integrated development Introduction

Principle of ecological efficiency:

proactive minimisation of the input of resources rather than reactive treatment of the waste by environmental technologies.

Principle of inherent safety:

proactive elimination of risks rather than reactive control by safety measures.

Principle of social acceptance:

proactive stakeholder discussion in case of socially relevant risks rather than reactive conflict regulation by mediation processes.

page 54

Integrated development of chemical products and processes is guided by:

K. Hungerbühler: Risk Analysis of Chemical Processes and Products, SS 2006 9

Framework: Integrated development Introduction

page 59 (example: process development)

K. Hungerbühler: risk analysis of chemical processes and products, SS 2005

10

Use of Design and Decision Tools

Diseconomy of Risk

Economy of Scale

Scale

Intensity

Pilot

Lab Plant

(Capacity Range)

Framework: Integrated development

Introduction

K. Hungerbühler: Risk Analysis of Chemical Processes and Products, SS 2006 11

Integrated Development and Decision Making

Introduction

K. Hungerbühler: Risk Analysis of Chemical Processes and Products, SS 2006 12

page 24

Integrated development and risk Integrated development takes into account different risks:

SO 2 NO 2

IDLH 270 42

MAK 5 3

MIK 0.03 0.03

Threshold limit values [mg m

-3] in Switzerland:

ch. 6

ch. 7, 9 ch. 5

Introduction

safety

health protection

environmental protection

– process RA – product RA

duration of exposure

in te n s it y o f e x p o s u re

IDLH = immediately dangerous to life or health ADI = acceptable daily intake

MAK = MAC: maximum allowable concentration MIK = MIC: maximum allowable immission conc.

RA = risk analysis

LCA = life cycle assessment

K. Hungerbühler: Risk Analysis of Chemical Processes and Products, SS 2006 13

An example for integrated development – Saquinavir ®

•precursor (1987)

•developed as a renin inhibitor.

•IC

50towards HIV protease = 27 nM

•product (1989)

•inactive towards renin.

•IC

50towards HIV protease = 1.9 nM

(IC

50= in vitro concentration for inhibiting 50% of the viruses as a measure for antiviral activity)

Product improvement

source: Chimia1996, 50, 532-537.

Introduction

K. Hungerbühler: Risk Analysis of Chemical Processes and Products, SS 2006 14

An example for integrated development – Saquinavir ® Process improvement

Research synthesis Production synthesis

number of chemical steps 26 11

overall yield 5% 50%

t chemicals / t product 700 13

t solvent / t product 5000 800

Introduction

K. Hungerbühler: Risk Analysis of Chemical Processes and Products, SS 2006 15

An example for integrated development – Saquinavir ® Introduction

Synthesis improvement by retro synthetic analysis of the target molecule:

K. Hungerbühler: Risk Analysis of Chemical Processes and Products, SS 2006 16

• introduction and outline

• objectives and content of the course, examination

• case study

• general aspects of “risk”

Introduction

K. Hungerbühler: Risk Analysis of Chemical Processes and Products, SS 2006 17

Learning goals Introduction

1. To understand the basic hazards of chemical processes and products to human health, the ecosphere and the

technosphere.

2. To gain insight into the systematic characterization of the hazard potential of chemical processes and products.

3. To obtain methodological know-how for the quantitative life

cycle and risk assessment of chemical processes and products.

4. To get used to the application of the assessment tools (pt. 3) for shaping chemical processes and products towards “Green Chemistry”.

Learning goals of the „Risk Analysis” course :

K. Hungerbühler: Risk Analysis of Chemical Processes and Products, SS 2006 18

Content of the course

dates topics of the course

04.4.06 introduction

11.4.06 life cycle assessment (LCA)

product risk analysis

04.7.06 outlook: ethics and risk

18.4.06 LCA

25.4.06 LCA

02.5.06 product risk analysis

09.5.06 product risk analysis

16.5.06 product risk analysis

23.5.06 process risk analysis

30.5.06 process risk analysis

06.6.06 compensation

13.6.06 thermal process safety

20.6.06 thermal process safety

27.6.06 industry: presentation of the case studies

Introduction

K. Hungerbühler: Risk Analysis of Chemical Processes and Products, SS 2006 19

Examination Introduction

knowledge field goal examples

I terms understanding basic terms and abbrevia- tions

risk, probability, consequences risk quotient, PEC, PNEC,

POCP, GWP, ignition point, TMR

adII models understanding fun- damental models and deriving basic equations

dose-effect, mixture toxicity exposure (local, multimedia)

heat balance (general, adiabatic,...) error / event tree

III concepts understanding fun- damental concepts with their underlying assumptions and limitations

runaway scenario

risk analysis (product, process) life cycle assessment

IV application of I-III to examples and to the case study

implementing the

knowledge

K. Hungerbühler: Risk Analysis of Chemical Processes and Products, SS 2006 20

• introduction and outline

• objectives and content of the course, examination

• case study

• general aspects of “risk”

Introduction

K. Hungerbühler: Risk Analysis of Chemical Processes and Products, SS 2006 21

Concept of the case study Introduction

Time-schedule of the case study:

date Steps

04.4.06 Short introduction, building groups 10.4.06 Introduction, work plan, strategy

20.6.06 Final version of the report 27.6.06 Excursion and presentation 08.5.06 Milestone I

To work on partial aspects, integration work, to draft the report

06.6.06 Milestone II

To prepare the presentation, first draft of the final report

K. Hungerbühler: Risk Analysis of Chemical Processes and Products, SS 2006 22

Case study 1

Risk analysis and life cycle assessment of an industrial solvent distillation

Tutor: Christian Capello; HCI G143; phone 044 633 4401;

christian.capello@chem.ethz.ch

• Investigation of the ecological and safety risks associated with the recycling of waste solvents

distillation plant:

K. Hungerbühler: Risk Analysis of Chemical Processes and Products, SS 2006 23

Case study 1

Tasks and methods

Process risk analysis

• Systematic search for hazards and determination of safe process conditions

• Qualitative estimation of hazardous incident scenarios (error tree) Product risk analysis

Life cycle assessment

• Ecological comparison and evaluation of the environmental impact of energy and material demand of various solvent treatment

technologies (recycling vs. thermal utilization)

• Risk assessment of the working environment

• Determination of environmental behaviour and concentrations

(simplified environmental models)

K. Hungerbühler: Risk Analysis of Chemical Processes and Products, SS 2006 24

Case study 2

Risk analysis and life cycle assessment of an agrochemical substance

Tutor: David Trudel; HCI G136; phone 044 636 4414; david.trudel@chem.ethz.ch

Starting point:

Cultivation of grain: lodging by rain and wind

Growth regulators in the cultivation of grain: culm shortening, increased stability, better harvest

Example substance: Trinexapac-Ethyl ® produced by Syngenta Crop Protection

Trinexapac-Ethyl

®:

OO

O

O OH

K. Hungerbühler: Risk Analysis of Chemical Processes and Products, SS 2006 25

Case study 2

Tasks and methods

Product risk analysis

• Modelling the concentration of Trinexapac-Ethyl in the environment, determination of limit values, estimation of the risk factor

• Exposure assessment of a farmer using Moddus (product with Trinexapac-Ethyl as active ingredient)

Process risk analysis

• Systematic search for hazards and determination of safe process conditions

• Thermal explosion risk

• Qualitative estimation of hazardous incident scenarios (error tree)

Life cycle assessment

• Energy balance of the cultivation of grain: which partial process is causing the biggest environmental load?

• Is the application of a growth factor energetically reasonable?

K. Hungerbühler: Risk Analysis of Chemical Processes and Products, SS 2006 26

• introduction and outline

• objectives and content of the course, examination

• case study

• general aspects of “risk”

Introduction

K. Hungerbühler: Risk Analysis of Chemical Processes and Products, SS 2006 27

Introduction Risk

Risk...

... as a venture

... as a possibility to fail to reach the

goal because of

disturbances.

K. Hungerbühler: Risk Analysis of Chemical Processes and Products, SS 2006 28

Financial risk

Kapitalwert

E intr itts wahr sc he inlic h k e it

µ1 µ2 σ1

σ2

The σ/μ risk concept of the capital market theory Introduction

capital value

R = f(σ/μ)

probability

μ1 μ2 σ2

σ1

K. Hungerbühler: Risk Analysis of Chemical Processes and Products, SS 2006 29

Chemical risk Safety, health and environmental risk exemplified by human toxicity

accidental case acute damage (worker/resident)

R = f(

probability/consequence)

normal case

long-term damage (worker/consumer)

R = f(

exposure,dose-effect)

normal case

contribution to indirect long-term damage (specific population)

R = f(

contribution to effect classe)

Introduction

safety

health protection

environmental protection

– process RA – product RA

duration of exposure

intensity of exposure

K. Hungerbühler: Risk Analysis of Chemical Processes and Products, SS 2006 30

Chemical risk Introduction

• risk = the potential of damage to human health, the ecosphere and the technosphere by specific conditions, circumstances or processes.

• risk = a measure for the characterisation of an undesired incident with respect to the occurrence probability (P) and the

consequences (C).

• risk = f(P,C)

p.12, 310

The probability/consequence concept of technological risks

K. Hungerbühler: Risk Analysis of Chemical Processes and Products, SS 2006 31

sociological layer of risk analysis

psychological layer of risk analysis

scientific-technical layer of risk analysis

Different rationalities in risk analysis Introduction

„rationality 1“

„rationality 2“

„rationality 3“

K. Hungerbühler: Risk Analysis of Chemical Processes and Products, SS 2006 32

Individual and collective risks

p.13

P

i= relevant persons or person groups, S

j= damage scenarios,

p

j= occurrence probability of scenarios, t

ij= individual death probability,

r

i= individual risk of person i, R

j= collective risk for the scenario j, R = overall risk

Introduction

persons / groups [P

i]

damage scenarios [S

j] individual risk [r

i]

collective

risk [R

j]

K. Hungerbühler: Risk Analysis of Chemical Processes and Products, SS 2006 33

Individual risk Introduction

Source: Lars Mülli, ‚Auswertung und Interpretation der schweizerischen Todesursachenstatistik für die Jahre 1980 bis 1999‘ (on the basis of data of the Federal Office for Statistics), final diploma report, September 2002.

Individual death risk for different age groups

Altersabhängige Sterbew ahrscheinlichkeit pro Geschlecht für zw ei Zeitperioden

1,00E-06 1,00E-05 1,00E-04 1,00E-03 1,00E-02 1,00E-01 1,00E+00

0 1 - 4 5 - 9 10 - 14 15 - 19 20 - 24 25 - 29 30 - 34 35 - 39 40 - 44 45 - 49 50 - 54 55 - 59 60 - 64 65 - 69 70 - 74 75 - 79 80 - 84 85 +

Alter

Sterbewahrscheinlichkeit

1980 - 1984 M

1995 - 1999 M

1980 - 1984 F

1995 - 1999 F

Share of death causes at the age of 20 – 24, 1995 – 1999 men: 12% diseases, 31% accidents, 57% violence/suicide women: 22% diseases, 24% accidents, 54% violence/suicide Age dependent mortality per gender for two time periods

mortality

0 1-4 5-9 10-14 15-19 20-24 25-29 30-34 35-39 40-44 45-49 50-54 55-59 60-64 65-69 70-74 75-79 80-84 85++

age (years)

K. Hungerbühler: Risk Analysis of Chemical Processes and Products, SS 2006 34

Individual risk Introduction

General individual death risk in the United Kingdom

Source: Spare, P.(1999): Loss Prevention Bulletin 145.

K. Hungerbühler: Risk Analysis of Chemical Processes and Products, SS 2006 35

Collective risk Collective risk: comparison of incident probability and extent of

damage (casualties) in case of natural and human-caused risks

Source: Parfitt, J.P.(1992):

Societal Risk estimated from historical data for the UK and world-wide events, SRDA-R5

death toll (N)

cumulative frequency of incidents ≥ N

Introduction

chemical industry cyclones

air traffic

earthquakes flooding

aridity

K. Hungerbühler: Risk Analysis of Chemical Processes and Products, SS 2006 36

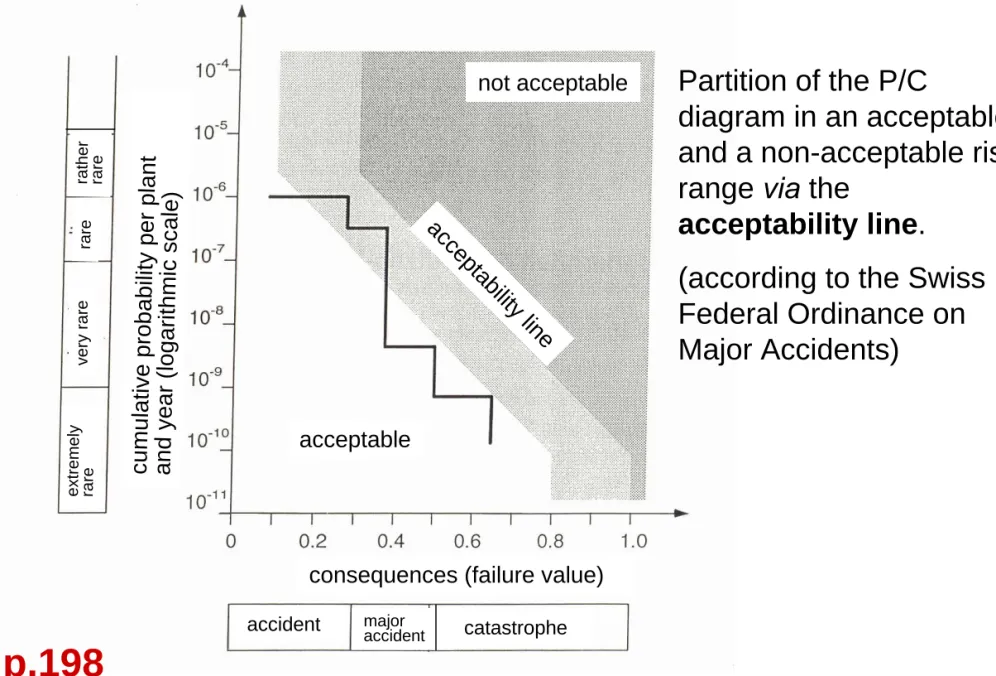

Collective risk assessment

p.198

Partition of the P/C

diagram in an acceptable and a non-acceptable risk range via the

acceptability line.

(according to the Swiss Federal Ordinance on Major Accidents)

Introduction

consequences (failure value) not acceptable

acceptable ac ce

pta bili ty lin e

major

accident

catastrophe accident

rareextremely rarevery rarerather rare

c u m u la ti v e p ro b a b ili ty p e r p la n t a n d y e a r (l o g a ri th m ic s c a le )

K. Hungerbühler: Risk Analysis of Chemical Processes and Products, SS 2006 37

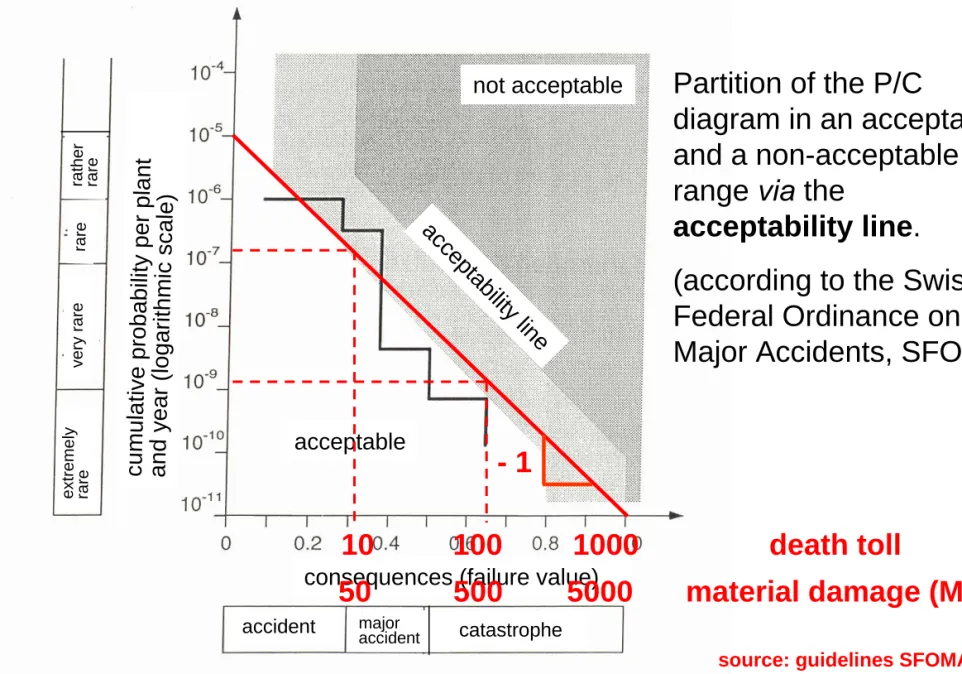

Collective risk assessment

Partition of the P/C

diagram in an acceptable and a non-acceptable risk range via the

acceptability line.

(according to the Swiss Federal Ordinance on Major Accidents, SFOMA) Introduction

consequences (failure value) not acceptable

acceptable ac ce

pta bili ty lin e

major

accident

catastrophe accident

rareextremely rarevery rarerather rare

c u m u la ti v e p ro b a b ili ty p e r p la n t a n d y e a r (l o g a ri th m ic s c a le )

death toll 1000

100 10

material damage (Mio SFr.)

source: guidelines SFOMA (1996)

5000 500

50

- 1

K. Hungerbühler: Risk Analysis of Chemical Processes and Products, SS 2006 38

Collective risk assessment Introduction

Collective risk: comparison of incident probability and extent of damage (death toll) in case of natural and

human-caused risks

Source: Parfitt, J.P.(1992):

Societal Risk estimated from historical data for the UK and world-wide events, SRDA-R5

chemical industry cyclones

air traffic

earthquakes flooding

aridity

P

cumdeath toll (N)

cumulative frequency of incidents ≥ N

10

010

-210

-410

-610

-8chemical industry cyclones

air traffic

earthquakes flooding

aridity

– 1

K. Hungerbühler: Risk Analysis of Chemical Processes and Products, SS 2006 39

Collective risk assessment Introduction

Risk aversion

Definition: risk aversion = enhanced awarness/weighting of

incidents that are least probable but of maximal outcome

Acceptability line (AL) with risk aversion:

r = risk

P = probability C = consequences

α = risk aversion ( α >1) R

AL= P · C α = const. = c α > 1

c dC

C α α – 1

1

C α –1

· c P

cumAL(C) = ∞

C

∫ =

log P

cumAL(C) = – ( α – 1) logC + c' e.g. with α = 2 : slope AL = – 1

α = 3 : slope AL = – 2

K. Hungerbühler: Risk Analysis of Chemical Processes and Products, SS 2006 40

Source: Kröger (1995), PSI

Costs of safety measures Introduction

Measure US $ per saved

human life

smear test 25’000

mobile treatment of heart attacks 15 - 30’000

safety belts front seats (USA) 100’000

improved side impact protection (USA) 800’000

safety belts back seats (USA) 3’200’000

safety limits for asbestos (USA) 8’300’000

aircraft grounding for DC-10 30’000’000

new multi-storey regulation (UK) 100’000’000 removal of asbestos in schools up to 1’400’000’000 hydrogen recombinators in nuclear plants 3’000’000’000 replacement of toxic wood preservatives by

ecological ones 5’700’000’000

K. Hungerbühler: Risk Analysis of Chemical Processes and Products, SS 2006 41

Individual risk and responsibility responsibility areas for different risk categories

individual death risk (per year)

Introduction

individual area of responsibility

collective area of responsibility

risk categories:

cat. 1 cat. 2 cat. 3 cat. 4

“voluntarily” big self- determination

small self-

determination “involuntarily”

5) commercial air travel 6) train passenger

7) fire impact in flat (infants aged 1-4) 1) drug usage

2) soar

3) car accident (driver) 4) car accident (co-driver)

K. Hungerbühler: Risk Analysis of Chemical Processes and Products, SS 2006 42

Poll on the perception of safety and risk Introduction

chemist chemical engineer environmental sciences F F F

(please indicate study subject area 6 )

I Handling of risk:

personal apportionment of responsibility

fate responsibility third party

responsibility personal responsibility

% % % Please indicate partition in percent: the sum must be 100% !

II My perception of the Chemical Industry in Switzerland:

professional competence

Min. Max.

1 2 3 4 5 6

credibility

Min. Max.

1 2 3 4 5 6

(please mark 6 )