Edited by:

Michael Gänzle, University of Alberta, Canada Reviewed by:

Sergio I. Martinez-Monteagudo, The Ohio State University, USA Rukma Reddy, U.S. Food and Drug Administration, USA Kazutaka Yamamoto, National Food Research Institute, National Agriculture and Food Research Organization, Japan

*Correspondence:

Rudi F. Vogel, Lehrstuhl für Technische Mikrobiologie, Technische Universität München, Gregor-Mendel-Straße 4, 85354 Freising, Germany rudi.vogel@wzw.tum.de

Specialty section:

This article was submitted to Food Microbiology, a section of the journal Frontiers in Microbiology Received: 17 April 2015 Accepted: 15 June 2015 Published: 03 July 2015 Citation:

Lenz CA, Reineke K, Knorr D and Vogel RF (2015) High pressure thermal inactivation of Clostridium botulinum type E endospores – kinetic modeling and mechanistic insights.

Front. Microbiol. 6:652.

doi: 10.3389/fmicb.2015.00652

High pressure thermal inactivation of Clostridium botulinum type E

endospores – kinetic modeling and mechanistic insights

Christian A. Lenz

1, Kai Reineke

2,3, Dietrich Knorr

3and Rudi F. Vogel

1*

1

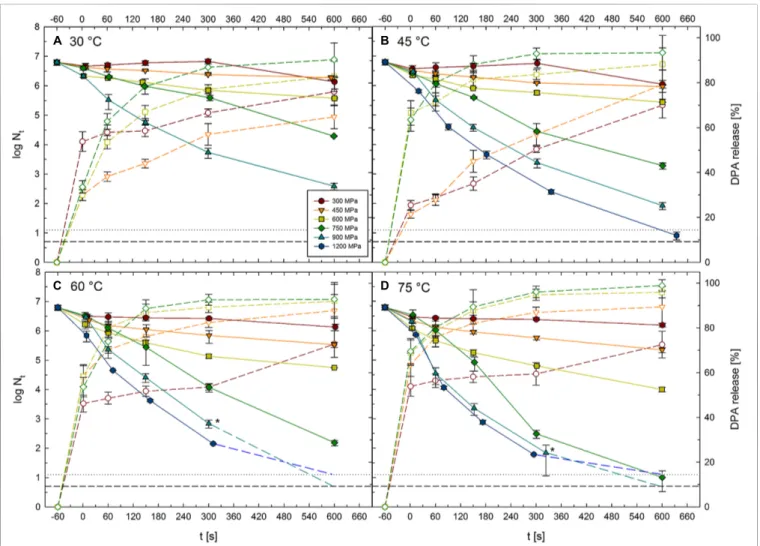

![FIGURE 2 | Mean inactivation levels of Clostridium botulinum TMW 2.990 spores after 60–600 s HPT treatments [log (N t /N 1s )] in different high pressure units](https://thumb-eu.123doks.com/thumbv2/1library_info/3882021.114327/5.892.67.827.687.977/figure-inactivation-levels-clostridium-botulinum-treatments-different-pressure.webp)

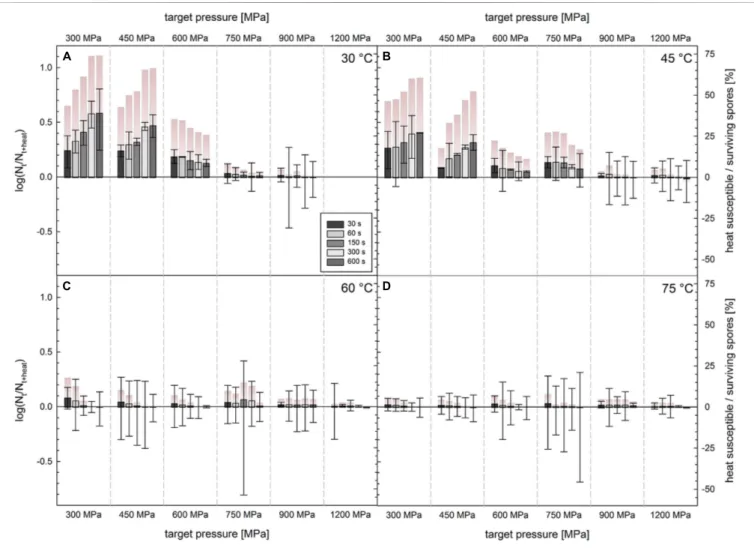

![FIGURE 5 | Difference in survivors of C. botulinum TMW 2.990 spores after HPT treatments enumerated on plate with and without lysozyme [log(N t + lysozyme /N t ); left y-axis]](https://thumb-eu.123doks.com/thumbv2/1library_info/3882021.114327/10.892.69.825.93.621/figure-difference-survivors-botulinum-treatments-enumerated-lysozyme-lysozyme.webp)