Research Collection

Journal Article

From macro- to micro-experiments: Specimen-size independent identification of plasticity and fracture properties

Author(s):

Gorji, Maysam B.; Furmanski, Jevan; Mohr, Dirk Publication Date:

2021-06-01 Permanent Link:

https://doi.org/10.3929/ethz-b-000478154

Originally published in:

International Journal of Mechanical Sciences 199, http://doi.org/10.1016/j.ijmecsci.2021.106389

Rights / License:

Creative Commons Attribution 4.0 International

This page was generated automatically upon download from the ETH Zurich Research Collection. For more information please consult the Terms of use.

ETH Library

ContentslistsavailableatScienceDirect

International Journal of Mechanical Sciences

journalhomepage:www.elsevier.com/locate/ijmecsci

From macro- to micro-experiments: Specimen-size independent identification of plasticity and fracture properties

Maysam B. Gorji

a,b, Jevan Furmanski

c, Dirk Mohr

a,d,∗aImpact and Crashworthiness Laboratory, Department of Mechanical Engineering, Massachusetts Institute of Technology (MIT), Cambridge MA, USA

bExponent Inc, Engineering and Scientific Consulting, Menlo Park, CA, USA

cCorporate Strategic Research, ExxonMobil Research and Engineering, Annandale, NJ, USA

dDepartment of Mechanical and Process Engineering, Swiss Federal Institute of Technology (ETH), Zurich, Switzerland

a r t i c le i n f o

Keywords:

Micro-fracture experiments Ductile fracture

Pipeline steel alloy API X52

a b s t r a ct

Thestress-strainresponseofmostengineeringmaterialscanbeconvenientlydeterminedusingwell-established macro-specimenswithouterdimensionsofseveralmillimetersorevencentimeters.However,inthecaseof curvedthin-walledstructuresorstructureswithspatialmaterialpropertygradients,itisoftenimpossibletoex- tractmacro-specimens.Forthefirstgroupofstructuresthespecimendimensionsaregreaterthanthestructural dimensions,whileforthesecondgroup,theassumptionofstatistically-homogeneousmaterialpropertiesisnot validthroughoutavolumeaslargeasthespecimengagesection.Afrequentlyencounteredexampleismaterial propertygradientsaroundweldsinmetallicstructuresorcastingsinautomotiveengineering.Inviewofcharac- terizingthelocalplasticityandfracturepropertiesatthemillimeterscale,amicro-testingtechniqueisdiscussed inthisstudy.Inaddition,themicroscopicexperimentalresultsof100𝜇mthicksteelalloyAPIX52arecompared tostandardmacroscopiccounterpartswith2mmthickness.Anewcustom-mademicro-testingdeviceisemployed toloaduniaxialtension,notched,centralholeandin-planeshearmicro-specimenswithaquasi-staticnominal actuatorstrainrateoflessthan1𝜇m/s.Thesemicro-scaleexperimentsonapipelinesteelareperformedunderan opticalmicroscope;aplanardigitalimagecorrelationisusedtocomputethesurfacestrainfields.Theplasticity andfractureinitiationmodelarethenderivedusingtheconventionalmacro-andmicro-experiments.Itiscon- cludedthatmicro-testingprovidesapowerfulmeanstocharacterizematerialswhosepropertiesarehomogeneous overafewhundredmicronsonly.

1. Introduction

Thestress-strainresponseofengineeringmaterialsisusuallydeter- minedfromexperimentsonspecimenswithdimensionsofafewmil- limeters.Mostexperimentalinfrastructureisdesignedfortestingsuch

“macro-specimens” whichincludesthemeasurementoftheforcesinthe kilonewtonrangeanddisplacementsinthemillimeterrange.Asanalter- native,micro-testingtechnologyhasalsobeendevelopedinresponseto thespecialneedsofdifferentfieldsofapplication.Oftenthematerialto becharacterizedisnotavailableintheformoflargeblocks.Forexam- ple,micro-andnano-indentationexperimentshavebeenemployedto gainsomeinsightintotheelasto-plasticpropertiesthroughinversenu- mericalanalysisortheoreticalestimates[1–4].However,miniaturized experimentswithhomogeneousmechanicalfieldsarestillthepreferred optionastheyprovidedirectaccesstothestress-strainresponsewithout makinganyaprioriassumptionsonconstitutiveresponseofamaterial.

∗Correspondingauthor.

E-mailaddress:mohr@mit.edu(D.Mohr).

Manydevelopmentsonmicro-testinghavebeendrivenbytheneed forexperimentaldataonthefailureofthinfilmsusedinmicroelectron- ics. Asanalternativetoextractingthespecimenfroma givenwork- piece,thin-film tensilespecimens canbe directlyfabricatedtoshape usinglithography.Yettheloadingandclampingofspecimenscanbe particularlychallenging.Forfilmthicknessesof1𝜇mandfewmicronsin width,theforcestobemeasuredareinthemilli-Newtonrange,thereby requiringspecializedsensorsandthemanagementofthermaldrifting.

Experimentalproceduresforthetestingoffreestandingthin-filmdog- bonespecimenshavebeenpresentedbySharpeetal.[5]andChasiotis andKnauss[6].Toavoidthehandlingoffree-standingspecimens,Es- pinosaetal.[7]proposedamembranedeflectiontechniquetoperform uniaxialtensionexperiments.Lateron,ZhuandEspinosa[8]developed anin-situ nanoscaletensile testingdevicetoidentifythemechanical properties anddeformationmechanismof nanotubes andnanowires.

The“lab-on-chip” typeofapproachhasbeenestablishedbyPardoenand co-workers[9–11].Inadditiontotestingdog-bonespecimens,Lietal.

[12]alsofabricatedflatnotchedtensionspecimenstogaininsightinto thefracturetoughnessofsingle-crystalsilicon.Xiangetal.[13]mea-

https://doi.org/10.1016/j.ijmecsci.2021.106389

Received26November2020;Receivedinrevisedform6March2021;Accepted7March2021 Availableonline11March2021

0020-7403/© 2021PublishedbyElsevierLtd.

suredthemechanicalpropertiesofthinfilmsusingamicro-bulgetest;

a2.8𝜇melectroplatedCufilmstudiedunderthepressurethatwaspro- videdbypumpingwater.Besidesthat,bendingtestswithdimensionsof afewmicronshavebeendevelopedbyHaqueandSaif[14]forcharac- terizingthinfilms.

Themicro-tensiontestingofmetalsinvolvesspecimenswithmini- mumdimensionsofafewmicrons.Inotherwords,thedimensionsof micro-specimensarestillabouttentimeslargerthanthin-film speci- mens,whichbringstheforcesupintotheNewtonrange.Atthislevel, strain-gage based load cells are sufficiently sensitivefor force mea- surement.Asanalternativetousingscanningelectronmicroscopyto monitorthespecimenthroughouttheexperiment,opticalmicroscopy canbeemployed.Mineetal.[15]madeuseoftensilespecimenswith 20×20𝜇mcross-sectionstocharacterizethestrengthandductilityof lathmartensite,aswellastorevealtheeffectsoftheblockandpacket grainboundaries.Intheirexperiments,theymadeuseofmicro-gluing grips[16]toattachtheelectrondischargemachinedspecimens.Ran andFu [17]proposed themicro-scaleflangedupsettingtechniqueto studythe ductile fracturein micro-forming processes by calculating the fractureenergy and subsequently predicting the fracturestrain.

Otherexamplesof theuseof micro-tensionspecimensfor investigat- ingthedeformationandfailuremechanismsatthegrainorsub-grain levelarefoundin[18–21].Asfarasmicro-compressiontestingiscon- cerned,itis worth notingthatRanandFu [22]developeda micro- scaleflangedupsettingtechniquetostudytheductilefractureduring micro-forming.

BonattiandMohr[23]developedamicro-tensiontestingdeviceto characterize16𝜇mthickaluminumalloy1235-H18foil,whichisused asacurrentcollector(cathode)inlithium-ionbatteries.Themechani- calbehaviorofthecomponentsoflithium-ionbatterieshasalsobeen investigatedbyZhuetal.[24].Theymadeuseof1mmwidespecimens tocharacterizethedeformationmechanismofbatterycellcomponents includingananode,acathode,andaseparator.Themicrostructureof thesecomponentssuchascrystalorientationandporesizewerealsoin- vestigatedusingelectronmicroscopyandX-raydiffractiontechniques.

Vasconcelosetal.[25,26]usedananoindenterinanargon-filledenvi- ronmenttomeasurethelocalmechanicalpropertiesoflithium-ionbat- teriesduringcharginganddischarging.Sheidaeietal.[27]performed tensiletestson25𝜇mthicksinglelayerpolypropyleneseparators;the foilswerecutbyarazorbladeinawaytohavealongstripwith6mm widthand15mmgagelength.Cannarellaetal.[28]usedasimilartech- niquetofindthemechanicalpropertiesofbatteryseparatorwith10mm widthand20mmgagelength.

Thepresentworkisprimarilymotivatedbycharacterizingtheplas- ticityandfracturepropertiesofthematerialinandaroundaseamweld inasteelpipeline.Thestructuralintegrityofpipelinesisofhighinter- esttotheoilandgasindustry.Thefracturepropertiesofpipelinema- terialsareimportantforassessingtheirstructuralintegrity.Estimates ofthefractureresistanceofpipelinesaretypicallymadeusingmacro- scopicexperiments.However,thesespecimensaretoolarge toassess thefractureresistanceintheheat-affectedzoneofaweld,whichinthe caseofelectricalresistanceweldscanbeasnarrowas1mm.Dobiand Junghans[29]cut miniflattensile specimenswith2mmgagewidth and0.5mmthicknessfromtheheat-affectedandfusion zones toob- tainthestress-straincurves.Rodríguezetal.[30]used2.5mmdiam- eterhemisphericalpunchwith4mmdieradiustocharacterizetheme- chanicalpropertiesoftheheat-affectedzone;theextractedspecimens are10mm×10mmwith0.5mmthickness.Micro-hardnesstesting[31–

33]inconjunctionwithnumericalsimulations[34,35]prescribesthe alternativetechniqueforcharacterizingthepropertiesofthewelding zone.However,thestresstriaxialitydependentfracturestrainsarenot accessiblewiththistechnique;itisatbestlimitedtocharacterizethe strainhardeningunderuniaxialstressconditions.Researchonductile fracturehasdemonstratedthatthestraintofractureofmetalsdepends heavilyonboththestresstriaxialityandtheLodeangleparameter[36–

39].Inresponsetothesefindings,comprehensivefracturetestingpro-

Table1

Chemicalcomposition specificationofa 50-year-oldAPI X65pipelinesteel.

Element Carbon [C] Manganese [Mn] Iron [Fe]

Weight [%] 0.34 1.28 98.38

Fig.1. SEMmicrographofetchedpearliteofpipelinesteelalloyAPIX65.

gramscoveringawiderangeofstressstateshavebeenproposedand successfullyimplementedforaluminumalloysandsteels[40–43].

Inviewofpredictingthefractureofstructureswithpropertygradi- entsatthemillimeterscale,itishencealsonecessarytodevelopthecor- respondingmicro-fracturetestingprogram.GorjiandMohr[44]made afirstattempttoestablishsuchabasicfracturetestingprogramatthe micro-level.However,theirexperimentson flataluminumspecimens withonlytwotothreegrainsalongthethicknessdirectionledtoplas- ticityandfracturepropertiesobtainedthroughmicro-testingthatwere slightlydifferentfromthoseobtainedthroughmacro-testing.Itis the goal ofthepresentworktocomparemicro-andmacro-experiments byusinghybridexperimental-numericalanalysis.InSection2,wede- scribethematerialandoutlinetheexperimentaltechniquesforthetest- ingofmacro-andmicro-specimens.Subsequently,thenumericalmod- elsforthehybridnumerical-experimentalanalysisareintroducedbe- forediscussingtheresultsinSection4andpresentingtheconclusions inSection5.

2. Experimental 2.1. Material

AllspecimensareextractedfromAPIX52steellinepipe(wallthick- ness,innerdiameter).Thechoiceismadeinanattempttosatisfyour scientificneeds(nearlyisotropicmetalwithagrainsizesmallerthan 50𝜇m), whileaddressing aproblemof highindustrialrelevance(de- terminationofthefracturepropertiesofagingpipelines).Thechemical compositionofthepipelinesteelisidentifiedthroughEnergy-Dispersive X-raySpectroscopy(EDS).Itrevealsiron,carbon,andmanganeseasthe mainalloyingelements(seeTable1)withmassfractionsthatarechar- acteristicofAPIX52pipelinesteel.

Fig.1showsthemicrostructureofthisparticularsteelasobtained throughscanningelectronmicroscopy(SEM).Thedarkgreyzonescor- respondtotheferritematrix,whilethelightgrayzonescorrespondto cementite.Theaveragegrainsizeintheplaneofthesheetsampleis about30μm.Hardnessmeasurementsonpipecross-sectionsindicated homogeneousmaterialpropertiesalongthethicknessdirection.

Fig.2. Drawingsof(a)standardmacrospecimens,(b)novelmicrospecimens;allunitsarein[mm].BluedotsindicatethestartandendpointsoftheDICextensometer.

2.2. Specimens

2.2.1. Macro-specimens

Theexperimentalprogramisdesignedforcharacterizingtheplastic- ityandfracturepropertiesofthepipelinesteel.Inadditiontoconven- tional

• uniaxialtension(UT)specimens,

wechosespecimensfromthebasicfracturetestingprogramoutlined byDunandandMohr(2010),

• Notchedtension(NT)specimenswithsymmetriccircularcut-outs

• CentralHole(CH)tensionspecimens aswellarecently-developed

• In-planeshear(SH)specimen[42]

TheexactdimensionsoftheseflatspecimensaregiveninFig.2.All specimensareextractedsuchthattheprimaryloadingaxisis always alignedwiththelongitudinalaxisofthepipes.Thespecimenprofile withanominalthicknessof2mmiscutbythewireElectricalDischarge Machining(EDM)usinga0.25mmwirediameter.

2.2.2. Micro-specimens

Abatchof micro-specimens isalsoextractedfrom thesamesteel linepipebasemetal.Forthis,thegeometriesofthemacro-specimens arescaleddownbyafactorof20inanaffinemanner.Asaresult,the targetthicknessofthemicro-specimensis100𝜇monly.InFig.2,the dimensionsof micro-specimensaredisplayedinredcolor.Asforthe macro-specimens,theprimaryaxisofloadingofallmicro-specimensis alignedwiththelongitudinalaxisofthepipe.Usingamicro-EDMwith a30𝜇mdiameterwire,theoperationiscompletedintwosteps:firstby slicingthethinsheettothedesiredthickness(100𝜇m)andthencutting thespecimencontours.

2.3. Testingprocedure

2.3.1. Macro-experiments

Themacro-specimensaretestedusingahydraulicuniversaltesting machine(Model8800,Instron)equippedwithhigh-pressureclampsand a100kNloadcell.Eachtestisperformedunderthequasi-staticloading conditionataconstantcross-headvelocity.Thelatterischosensuchthat anaveragestrainrateoftheorderof10−3/sisobtainedfortheuniaxial test,andof2×10−4/sinallotherexperiments(seeTable2).Arandom finepatternofblackspeckles(averagespecklesizeofabout80𝜇m)is appliedontothespecimensurface,andadigitalcamera(ModelPoint

Table2

Standard-experimentconditions.

Standard- specimen Nominal actuator velocity [ 𝜇m/ s] Average strain rate [/s]

Uniaxial (UT) 40 1 ×10 −3

Notched (NT) 6 2 ×10 −4

Central hole (CH) 6 2 ×10 −4

Smiley shear (SH) 6 2 ×10 −4

GreywithTokinalenses,AT-XPROseries)isemployedtoacquirehigh- resolutionimages(2448×2048pixelsresultinginaspatialresolution ofabout40𝜇m/pixel)atafrequencyof1Hz.Basedontheacquired images,thesurfacedisplacementandstrainfields aredeterminedus- ingPlanarDigitalImageCorrelation(DIC,VIC2D-CorrelatedSolutions) withtypicalsubsetsizeof21pixelsandastepsizeof5.Inparticular, theprincipalsurfacestrains𝜀Iand𝜀II,andtheeffectivestrain

̄𝜀𝑒𝑓𝑓= 2

√3

√𝜀2𝐼+𝜀𝐼𝜀𝐼𝐼+ 𝜀2𝐼𝐼 (1)

areusedwhendiscussingtheexperimentalresults.

2.3.2. Micro-experiments

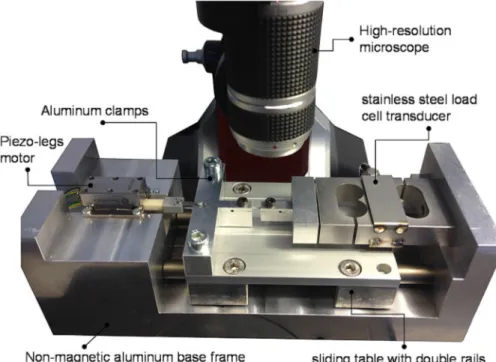

Acustom-mademicrotestingdeviceisusedtoperformallexperi- ments(GorjiandMohr[44].AsshowninFig.3,thisminiaturedevice includesalowfrictionslidethatis mountedontoanaluminumbase frame.Thepositionoftheslideiscontrolledthroughalinearpiezo-legs motor.Afirstspecimenclampismountedontotheslide,whilethesec- ondspecimen gripismountedontoastrain-gagedloadcell(Omega, modelLCM101-100), whichisbolted ontothebase frame.Themost importantfeatureofthisdeviceisthespecimengrip,whichfeaturesa receivingslotforspecimensofupto200𝜇mthickness.Tomaintaina highgeometricaccuracyduringclamping,theclampsarenotfloating;

insteadareanintegralpartofthegrip.Theydeformelasticallywhile theclampingforceisappliedthroughanM3tighteningscrew,thereby ensuringalinearmotionalongthespecimenthicknessdirectiononly.

Thetestingdeviceisusedin-situtoallowforthereal-timemonitor- ingofthespecimensurfacebyanopticalmicroscope(Keyence,model VHX-5000). The microscope operating at a magnification of about 200 ×isalso instrumentalforensuringtheaccurateinitial position- ingofthespecimeninsidethetestingdevice.Thetestingprocedurefor themicroexperimentsisverysimilartothatofthemacro-experiments.

Table3liststheactuatorvelocityformicro-testingthatresultedinap- proximatelythesamestrainratesasinthemacro-experiments.Themain differencebetweenmicro-andmacro-displacementsliesinthedisplace- mentfieldmeasurements.Inthemicro-experiments,DICisperformed onimagesfeaturingaresolutionof1600×1200pixels(withaspatial resolutionofabout2.0𝜇m/pixel).PreliminaryDICverificationforrigid bodymotionturnedouttobesuccessfulwhenusingthenaturalsurface

Fig.3. Miniaturetensilemachine.

Table3

Micro-experimentconditions.

Micro- specimen Nominal actuator velocity [ 𝜇m/ s] Average strain rate [/s]

Uniaxial (μ-UT) 2 1 ×10 −3

Notched (μ-NT) 0.3 2 ×10 −4

Central hole (μ-CH) 0.3 2 ×10 −4

Smiley shear (μ-SH) 0.3 2 ×10 −4

contrastforcorrelation.However,thecorrelationwaslostwhenthema- terialisdeformed,likelyduetoout-of-planedeformation.Consequently, DICisonlyusedtodeterminetherelativedisplacementofthespecimen shouldersinthecaseofthemicro-specimens.

3. Numerical

Irrespectiveofthespecimengeometry(macroormicro),thematerial isconsideredasahomogeneoussolidandmodeledusinggradient-free phenomenologicalplasticityandfractureinitiationmodels.Morespecif- ically,weemploythevonMisesplasticitymodelwithisotropicharden- ingandaHosford-Coulombfractureinitiationmodel.Bothformulations arebrieflyrecalledinthenexttwosubsections,beforeprovidingdetails onthefiniteelementmodels.Wenotethattheintroductionofkinematic and/ordistortionalhardeningmaybenecessarytoimprovethemodel predictionsforexperimentswithloadingdirectionreversal.

3.1. J2plasticitywithisotropichardening

TheyieldconditioniswrittenintermsofthevonMisesequivalent stress,̄𝜎,andahardeningdependentdeformationresistance,k, 𝑓= ̄𝜎−𝑘[

̄𝜀𝑝]

=0with̄𝜎=√ 3𝐽2=√

3∕2𝒔∶𝒔 (2)

wheresisthedeviatoricpartoftheCauchystresstensor.Theevolution ofthedeformationresistancekisexpressedasafunctionof thevon Misesequivalentplasticstrain,̄𝜀𝑝(isotropichardeninglaw),

𝑘[

̄𝜀𝑝]

=𝛼𝐴(

̄𝜀𝑝+𝜀0

)𝑛+(1−𝛼)( 𝑘0+𝑄(

1−𝑒−𝛽 ̄𝜀𝑝))

. (3)

Thehardeningfunctioniscomposedofpowerlaw(Swifttermwith {A,n,𝜀0}parameters[45]andanexponentiallaw(Voce termwith {k0,Q, 𝛽}parameters[46],withtheSwift-Voceweightingfactor𝛼.

3.2. Fractureinitiationmodel

TheHosford-Coulomb phenomenologicalfractureinitiationmodel [47]isemployedinthisstudytodescribetheonsetoffractureatlow- stresstriaxialities.Thestressstateischaracterizedbythestresstriaxi- ality(𝜂)andtheLodeangleparameter(̄𝜃).Thestresstriaxialityisthe ratioofthemeanstressoverthevonMises stress(aratioofthefirst stressinvariantandseconddeviatoricstresstensorinvariant).TheLode angleparametermeasurestheratioofthethirdandseconddeviatoric stresstensorinvariants,

𝜂= 𝐼1

√27𝐽2

,̄𝜃=1− 2 𝜋cos−1

[ 9 2√ 3

𝐽3

(𝐽2

)3∕2

]

(4)

where,

𝐼1=tr[𝝈];𝐽2=1

2𝐬∶𝐬;𝐽3=det[𝐬] (5) TheLodeparameterandstresstriaxialitydependentfractureinitia- tionmodeliscastintoadamageindicatorframework[48].Assuming D=0fortheplasticallyundeformedmaterial,fractureisassumedtoini- tiatewhenthedamageindicatorattainsunity(D=1)afterincreasing accordingtotheevolutionequation

𝑑𝐷= 𝑑𝜀𝑝

𝜀𝑝𝑟[

𝜂,𝜃]. (6)

InEq.(6), ̄𝜀𝑝𝑟denotesthestraintofractureforproportionalloading (constantstresstriaxialityandLodeparameterallthewayuntilfracture

initiation),

̄𝜀𝑝𝑟[ 𝜂,̄𝜃]

=𝑏(1+𝑐)

1𝑝

× ({1

2 (𝑓1−𝑓2

)𝑎

+1 2

(𝑓2−𝑓3

)𝑎

+1 2

(𝑓1− −𝑓3

)𝑎}1𝑎 +𝑐(

2𝜂+𝑓1+𝑓3

))−1𝑝

(7) with the transformation parameter p = 0.1 and the Lode angle parameter-dependentfunctions,

𝑓1

[̄𝜃]

= 2 3cos[𝜋

6 (1−̄𝜃)]

, 𝑓2

[̄𝜃]

= 2 3cos

[𝜋 6

(3+̄𝜃)]

, 𝑓3

[̄𝜃]

=−2 3cos[𝜋

6 (1+̄𝜃)]

.

(8)

TheHosford-Coulombmodelfeaturesthreematerialdependentpa- rameters:(i)theHosfordexponenta,whichcontrols theinfluenceof theLodeangleparameter,(ii)thestraintofractureforuniaxialtension, b,and(iii)thefrictioncoefficientc,whichcontrolsthestresstriaxiality influenceonthestrainofthefracture.

3.3. FEmodeling

Allfiniteelementsimulationsareperformedusingtheexplicitsolver ofthenonlinearFE-codeLS-DYNA. Inallspecimens, themechanical fieldsaresymmetricwithrespecttothelongitudinalplanes,whichis takenintoaccountthroughsymmetryconditions.Eightfirst-ordersolid elementsthroughoutthe(half-)thicknesswithanaverageedge-length of0.1mmand0.005mm(downscaledbyafactorof20×)areusedfor themacro-andmicro-specimenmeshes,respectively.Furthermore,for theUT-,NT-andCH-specimens,twoadditionalsymmetryconditions alongthelongitudinalandtransverseplanesatthespecimencenterare assumed.Theaxialdisplacementhistoryisappliedthroughasmooth velocityramp.Toenableadirectcomparisonofthesimulationswiththe experimentalresults,therelativeaxialdisplacementisreportedfortwo nodesthatarepositionedsymmetricallywithrespecttothespecimen centeratadistanceof30mmand1.5mm(downscaledbyafactorof20

×)ofthestandardmacro-andmicro-specimens,respectively.Numerical simulationsarecarriedoutforeachexperimentperformed.Toensurean accuraterepresentationoftheexperiments,thethicknessofthemeshes isalwaysadjustedtothemeasuredthicknessofagivenspecimen.

4. Results

4.1. Resultsfrommacro-experiments

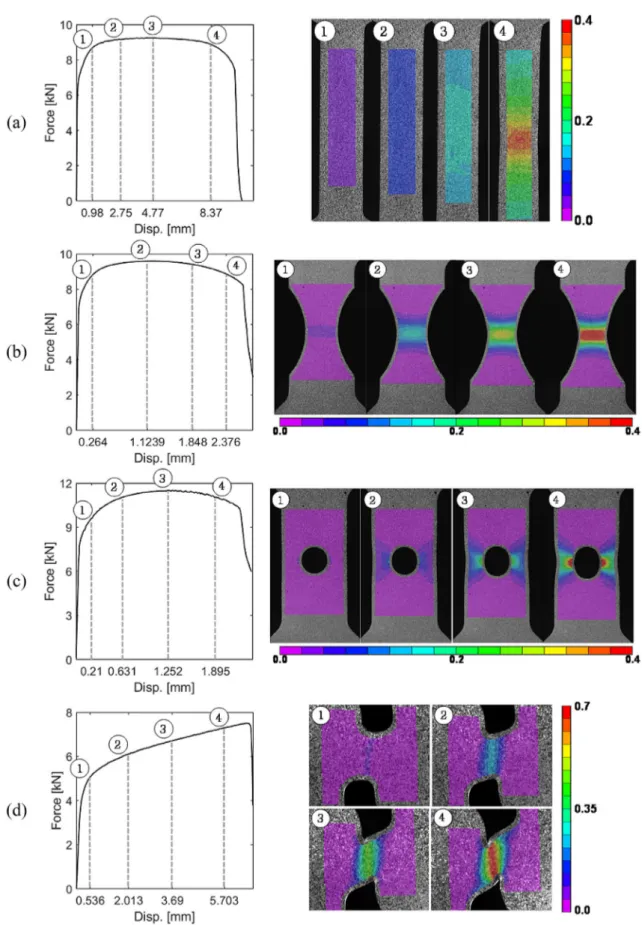

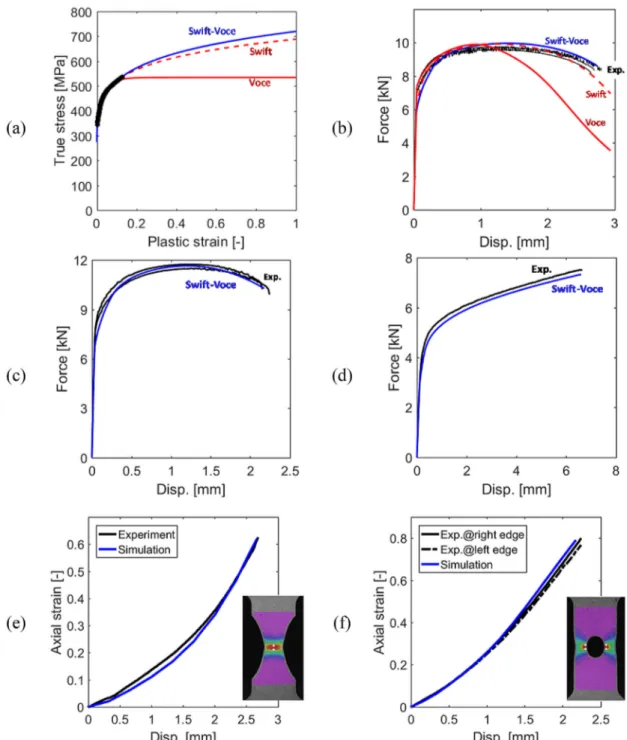

Fig.4showstheforce-displacementcurvesobtainedfromthemacro- scopicexperiments.Recallthatthedisplacementisreportedforavirtual extensometerlengthof30mm(seebluedotsinFig.2).Themeasuredten- sileresponseforthemacro-UTspecimensisseeninFig.4a,wherethe forcereachesamaximumof9.2kNatanengineeringstrainof0.16(point

○).3 Uptothispoint,theeffectivesurfacestrainfieldishomogeneous.Be- yondpoint○3,theplasticdeformationconcentratesinanarrowerband untilfractureinitiatesataforceof7.65kNanddisplacementof9.77mm (i.e.anengineeringstrainof0.32forthe30mmextensometer),while themaximumplanareffectivesurfacestrainattains0.81.

Theresultsfromarepresentativeexperimentonaflattensilespec- imenwithcircularcutouts(macro-NT)aresummarizedinFig.4b.It exhibitsa maximum force of 9.59kNat a displacement of 1.12mm (point○2).Thestrainsareconcentratednearthecenterofthespecimen throughout theentireloadinghistory.Themaximum effectivestrain onthespecimensurfaceinthelaststepbeforethefractureis0.66.At theinstantoffractureinitiation,theforce anddisplacementreached 8.18kNand2.645mm,respectively.

Inthe tensile experiments on macro-CH specimens (seeFig. 4c), amaximumforceof 11.5kNisobservedatadisplacementof1.25mm

(point○).3 Fractureinitiatesat10.2kNafterapplyingadisplacementof 2.23mm(seeFig.5c).Thesurfacestrainfieldpreservesitslongitudinal symmetryduringtheentireexperiment:apronounceddeformationcon- centrationduringtheentirestretchingisobservedneartheholebound- ary,reachingupto0.79justbeforefracture.

Theforce-displacementcurveforthemacro-SHisqualitativelydif- ferentfrom theotherconfigurationsinthesensethatitdoesnot ex- hibitanylocalmaximuminforce.AsseeninFig.4d,theforceincreases monotonicallyuntilfractureinitiates.Themaximumeffectivestrainon thespecimensurfacereaches0.80justbeforeformingthefirstcrack;

themaximumforcereaches7.5kNatadisplacementof6.6mm.

4.2. Resultsfrommicro-experiments

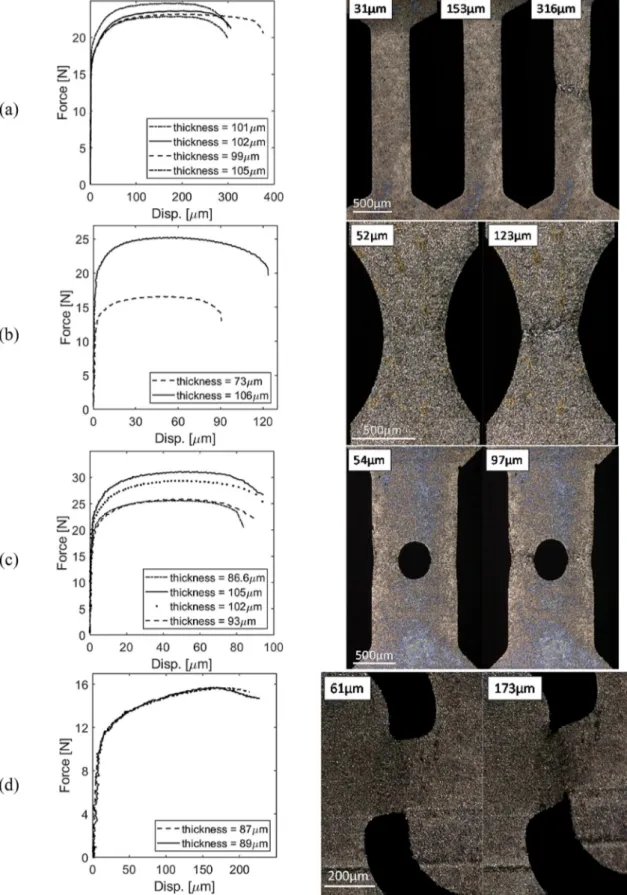

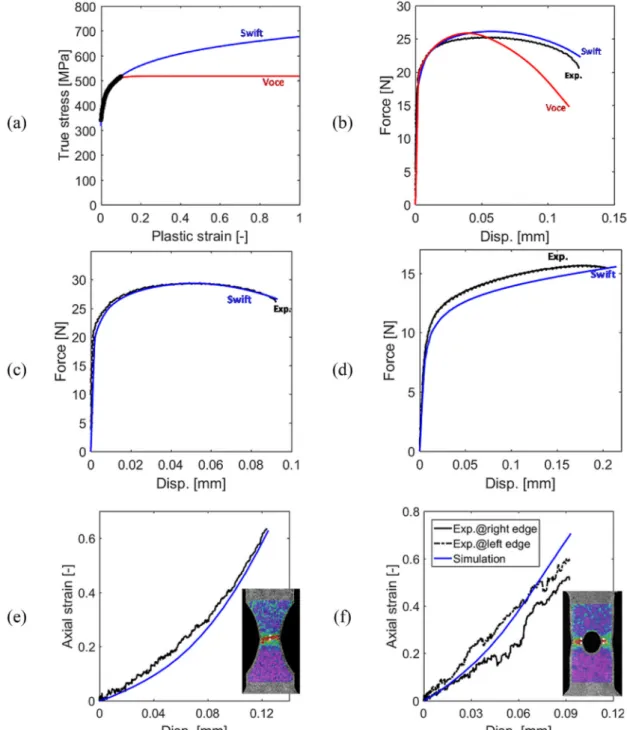

The force-displacement responses obtained after processing the recordingsfromμ-UTexperimentswithavirtualextensometerlength of1.5mmarepresentedinFig.5a.Overallthesamephenomenological responseasinthecorrespondingmacroscopicexperimentsisseen:pos- itivestrainhardening,followedbylocalizedneckingafterforcemaxi- mum,followedbyfractureinitiation.Significantvariationsareobserved whencomparingtheforce-displacementcurvesfromrepeatedexperi- ments.Theforceofthestrongestspecimenisabout8%higherthanthat of theweakest,whichisdirectlycorrelatedwiththevariationin ini- tialthickness:theweakestspecimenwasonly99𝜇mthick,whilethe strongestwas105𝜇mthick.Thedisplacementtofracturealsovaries from specimen-to-specimen,rangingroughly from290𝜇m to370𝜇m.

However,thevariationdoesnotcorrelatewiththespecimenthickness.

Wealsonotethattheforcemaximumoccursforallspecimensatapprox- imatelythesamedisplacement.Forinstance,inthecaseofμ-UTwith 102𝜇mthicknessand499𝜇mwidth(solidblacklineinFig.5a),themax- imumforceof23.6Nisattainedatadisplacementof153𝜇m.Theforce attheinstantofthespecimenfractureis21.5N,whichisreachedafter applyingadisplacementofabout300𝜇m(equatingtoanengineering strainof0.2forthe1.5mmlongextensometer).

Measurementswithaprofilometer(BrukerDXTStylus)reveallocal thicknessfluctuationsof±2𝜇m(Fig.6a).TheSEMimageofanunde- formedspecimen providesmore insightintothenatureof thethick- nessvariations(Fig.6b).For100𝜇mthickspecimens,suchvariations inthicknessareexpectedtocausespatialvariationsinthestressofat least2%whichwouldcontributetothedevelopmentofheterogeneous strainfieldsasthestrainhardeningcapacityofthematerialceases.

Theforce-displacementresponsesoftwoextremalμ-NTsareshown inFig.5b.Recallthatthedisplacementisreportedforavirtualexten- someterlengthof1.5mm,whichisshownbybluedotsinFig.2.Theex- perimentalresultsshowsignificantvariationsasafunctionofthespec- imenthickness:53%differenceinmaximumforcelevel(25.2Nversus 16.5N)and35%differenceinthefracturedisplacement(123.2𝜇mver- sus91𝜇m)for106𝜇mand73𝜇mthickspecimens.Similartothemacro- NTexperiments,fractureoccursatthespecimencenterforallμ-NTspec- imens,developingaflatbutslantedcracksurface(seeFig.5b).

Theforce-displacementcurvesoftheμ-CHexperimentsaredisplayed in Fig.5c.Likeotherconfigurations, therearesignificantdifferences between thetargetedthickness(100𝜇m)andthemeasuredthickness (varyingfrom86to105𝜇m)ofthereceivedspecimens.Asaresult,the maximum force variesbetween 25.8Nand31N (20%variation) and thefracturedisplacementvariesbetween 80𝜇mand94𝜇m(17%vari- ation).Theoverallspecimenresponseissimilartothatobservedinthe macroscopicexperiments.Forexample,the105𝜇mthickμ-CHspeci- menreachesamaximumforceof 31Natadisplacementof54𝜇m(the blacksolidlineinFig.5c);fractureinitiatesataforceof27Nandata displacementof91𝜇m.

Theforce-displacementcurvesfor87and89𝜇mthickmicro-SHspec- imensareshowninFig.5d.Themaximumforceofabout15.7Ndevelops atadisplacementofabout182𝜇minbothexperiments,whilefracture initiatesatadisplacementofabout200𝜇m.Similartothemacroscopic experiments,theshapeofthenotcheschangessubstantiallythrough-

Fig.4. Macro-experiments;force-displacementcurveandstraindistributionof(a)macro-UT,(b)macro-NT,(c)macro-CH,(d)macro-SH.

Fig.5. Force-displacementcurveanddeformingspecimens(correspondingtotheblacksolidlinesinforce-displacementcurves)of(a)μ-UT,(b)μ -NT,(c)μ -CH, (d)μ -SH.

Fig.6. (a)Roughnessmeasurementofastud- iedmicro-specimenwithaprofilometer.(b) SEMimageofanundeformedmicro-specimen.

outtheμ-SH experimentsfrom initiallyblunttosharpattheinstant of specimenfracture.The mostimportantdifference ascomparedto theresultsfromthemacro-experimentsistheobservationof aforce- maximumbeforefractureinitiation.Closerpost-morteminspectionof theμ-SHspecimensrevealstracesfromtheout-of-planemotionofthe specimenmid-plane,i.e.thespecimensarenolongerflat.Theobserved force-maximumisthustentativelyattributedtoplasticbucklingofthe shearedgagesectionshortlybeforeafractureinitiation.

4.3. Directcomparisonoftheresultsfrommacro-andmicro-experiments

4.3.1. Theoreticalconsiderations

AsmentionedinSection2,thegeometryofthemicro-specimenscor- respondstoadownscaledversionofthemacro-specimens(byafactor of𝜆=0.1

2 =0.05,consideringtheuniformthicknessof2mmformacro- specimensandaveragethicknessof100𝜇mformicro-specimens).From atheoreticalpointofview,themathematicalboundaryvalueproblems (BVP)aresimilar.Atthemacroscopiclevel,considerthekinematically- admissibledisplacementfield

𝐮=𝐮[𝐱] (9)

asafunctionof thepositionvectorx.Thedisplacementgradient∇u (second-ordertensor)reads

𝐝𝐮=(∇𝐮)𝐝𝐱 (10)

whilethestraintensor𝜺isanon-linearfunctionofthedimensionless displacementgradient,andtheCauchystresstensor𝝈 isanon-linear functionofthestraintensor,whichsatisfiesthefieldequation

𝑑𝑖𝑣𝝈=𝟎 (11)

anditsboundaryconditions.

Next,considerthedisplacementfieldinamicro-specimen, 𝐮𝜇=𝐮𝜇[

𝐱𝜇]

(12) withthescaledvectors

𝐱𝜇=𝜆𝐱. (13)

describingtheinitial positionof thematerialpoints within amicro- specimen.

Foradisplacement-drivenmechanicalproblem,choosingthemicro- displacementfield

𝐮𝜇=𝜆𝐮[1 𝜆𝐱𝜇]

(14)

willleadtoanexactsolutionoftheBVPforthemicro-specimens.Defin- ingthemicro-displacementgradient∇𝜇uas

𝐝𝐮𝜇=(∇𝜇𝐮)𝐝𝐱𝜇 (15)

wehave 𝐝𝐮𝜇=𝜆𝐝𝐮[1

𝜆𝐱𝜇]

=𝜆∇𝐮[1 𝜆𝐱𝜇]

𝐝𝐱=∇𝐮[1 𝜆𝐱𝜇]

𝜆𝐝𝐱=∇𝐮[1 𝜆𝐱𝜇]

𝐝𝐱𝜇 (16) andhence

∇𝜇𝐮[ 𝐱𝜇]

=∇𝐮[1 𝜆𝐱𝜇]

(17)

Inotherwords,thedisplacementgradientatapositionx𝜇inamicro- specimenisthesameasthatataposition𝐱=1𝜆𝐱𝜇inthecorresponding macro-specimenprovidedthattheapplieddisplacementsalsoscalewith thesamefactor𝜆astheirinitialgeometry.Italsofollowsfromtheabove

considerationthatstrainandstressatapositionx𝜇inamicro-specimen isthesameasthatataposition𝐱=1𝜆𝐱𝜇inthemacro-specimen, 𝝈𝜇[

𝐱𝜇]

=𝝈[1 𝜆𝐱𝜇]

(18)

Theforceactingofaflatboundarysurface(Finthemacro-andF𝜇 forthemicro-specimen)thenscaleswith𝜆2,

𝐹𝜇=

∫𝐴

𝝈𝜇(𝑑𝑥𝜇)(𝑑𝑦𝜇)=

∫𝐴

𝝈(𝜆𝑑𝑥)(𝜆𝑑𝑦)=𝜆2∫

𝐴

𝝈(𝑑𝑥)(𝑑𝑦)=𝜆2𝐹. (19)

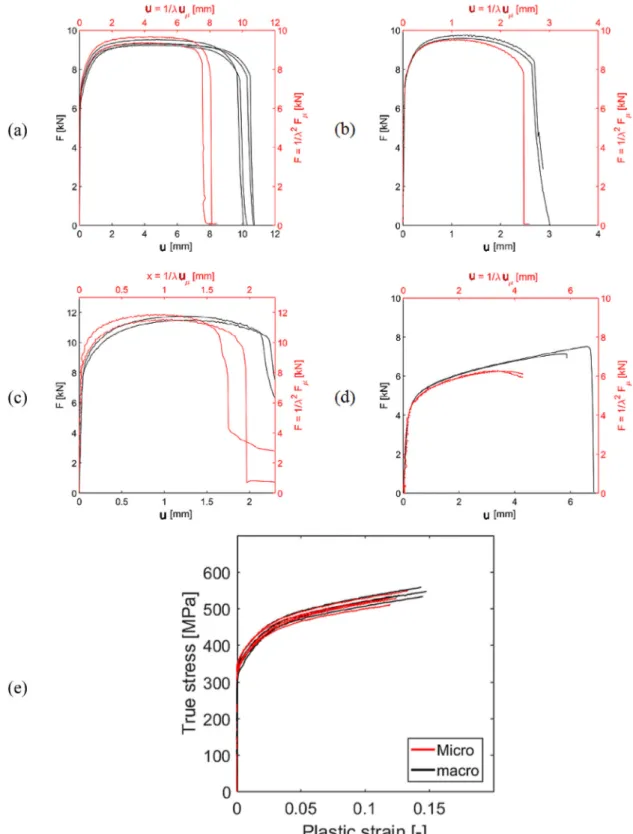

4.3.2. Comparisonofselectedexperimentalresults

For each type of specimen, we compare the recorded force- displacement curve of macro-experiments (solid black lines) versus scaledF−uofmicro-experiment(solidredlines)that𝐹 =𝜆12𝐹𝜇and 𝐮=1

𝜆𝐮𝜇;giventhatthein-planedimensionscaleswithabout𝜆=0.05.

Asaresult,theobtainedforcelevelisalmostidenticalforthemacro- andmicro-specimensprovidedthatallspecimendimensionshavebeen scaledwiththesamefactor.Undertheuniaxialloadingcondition(see Fig.7a),themaximumforcelevelinbothmicro-andmacro-scalesat- tainstheaveragevalueof9.2kN.Thevariationsofbothscalesareat- tributedtothenon-homogeneousmaterialpropertiesof theAPIX65 pipelinesteel.Weobtainthesamelevelofforceinmicro-andmacro- specimensforothergeometries(Fig.7b-d).

Amoresignificantdifferencebetweenmacro-andmicro-resultsis observedwhencomparing thefracturedisplacement. Thefracturein micro-specimensinitiatesearlierascomparedtothemacro-specimens.

Forexample,thedisplacementsattheinstantoffractureformacro-UT andμ-UT areufrac = 10.08mmand𝐮𝑓𝑟𝑎𝑐=1

𝜆𝐮𝑓𝑟𝑎𝑐𝜇 =7.78mm, respec- tively(seeFig.7a).Correspondingresponsesformacro-NTandμ-NT areufrac=2.66mmand𝐮𝑓𝑟𝑎𝑐=𝜆1𝐮𝑓𝑟𝑎𝑐𝜇 =2.47mm(seeFig.7b)andfor macro-CHandμ-CHareufrac=2.19mmand𝐮𝑓𝑟𝑎𝑐= 1𝜆𝐮𝑓𝑟𝑎𝑐𝜇 =1.78mm, respectively(seeFig.7c). Asimilar differenceisobservedforthein- planeshearconfigurationwhilefractureinitiatesattheaverageddis- placementofufrac=6mmforthemacro-SHandatthescaleddisplace- mentof𝐮𝑓𝑟𝑎𝑐= 1𝜆𝐮𝑓𝑟𝑎𝑐𝜇 =4.1mmfortheμ-SH(seeFig.7d).

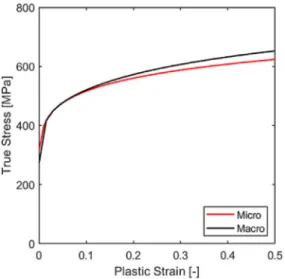

Theresultsoftheuniaxialtensionexperiments(recordedforceand elongationofUTandμ-UTtest)areevaluateduptothemaximumforce.

Usingstandardequations,thetruestressiscalculatedastheratioofthe forceandthecurrentareaofthecross-section.Fig.7edepictselicited hardeningcurvesofthestudiedalloyforbothUTandμ-UT,uptothe maximumtensileforce.Theobtainedaveragedproofstrengthsofthe sheet specimenare350MPaand 351MPaforthemacro- andmicro- approach,respectively.Ascanbeobservedinthisfigure,themeasured flowcurvesoftheμ-UTsarepracticallylikethestandardones.

4.4. Numericalsimulationresults

4.4.1. Force-displacementresponseformacro-specimens

Thehybridnumerical-experimentalapproachisusedtodescribethe hardeningcurveofthematerial.Fig.8adisplaysthehardeningcurve extendedfromthemacro-UTtest,alongwiththeVoceandSwiftapprox- imation.Inafirststep,theVoceandSwiftlawsarefittedindependently toapproximatethetruestress-straincurveuptotheonsetofnecking (Fig8a).Inasecondstep,numericalsimulationsareperformedmacro- NTexperimenttoidentifythemixingratio𝛼whichprimarilyaffectsthe hardeningresponseforlargestrains(seeFig.8b).Fromcomparingthe simulatedandexperimentally-measureforce-displacementcurves,itis foundthatthecombinedSwift-Vocelawwith𝛼=1.2(seeEq.3)pro- videsthebestapproximation.Table4liststheSwift-Voceparameters obtainedfromconventionalmacroscopicexperiments.

Thederivedhardeningcurveisthenemployedtopredicttheforce- displacementresponsesforthecentralholeandin-planeshearexperi- ments.ThebluecurvesinFig.8cand8ddepictthecalculatedresponses ofmacro-CHandmacro-SHexperiments,respectively.Theyareingood

agreementwiththeexperimentalmeasurements(blackcurves).Thenu- mericalsimulationslightlyunderestimatestheforceatthebeginningof theCH-experiment,whiletheagreementimprovesforlarge displace- ments.Theforce-displacementcurveforthemacro-SHincreasesmono- tonicallyuntilasharpdropinforce;theFEpredictionis2%lowerthan theexperimentalcurveforshear.Theevolutionofthelocallogarithmic axialstrainforthemacro-NTandthemacro-CHisshowninFig.8eand 8f,respectively.There isagoodagreementoftheexperimentalmea- surementsandthenumericalresults.Allsimulationis stoppedwhen theexperimentallymeasuredfracturedisplacementisreached.Atthat instant,thelocalaxialstrain(onthespecimensurface)reaches0.61and 0.79forthemacro-NTandthemacro-CHspecimens,respectively.

4.4.2. Force-displacementresponseformicro-specimens

Forthemicro-experiment,thesamehybridnumerical-experimental approachisappliedtoretrievethematerialproperties.Asisshownin Fig.9a,thehardeningcurveis validatedthroughtheμ-UTuptothe plasticstrainofabout0.15,whichistheonsetofnecking.TheFEpre- dictionsoftheμ-NTspecimenresponseareshowninFig.9bforboth theSwiftandVoceapproximation.TheFE simulationwiththeVoce functionunderestimatestheforceandpredictsfailureatadisplacement of 36𝜇m,whilethesimulationwithSwifthardeningprovidesagood agreementwiththeexperimentalcurve.Themaximumerroris3%ata displacementof58𝜇m(experimentalmeasurementandnumericalresult deliver25.3Nand26.1N,respectively).TheSwiftparameters,obtained fromthemicro-approach,aresummarizedinTable4.Thederivedstress- straincurveisalsovalidatedforμ-CHandμ-SH;thesimulatedforce- displacementcurvesoftheseconfigurationsareshowninFigs.9cand 9d(solidbluecurves).Thereisagoodagreementfortheμ-CHspecimens (blackdotsinFig.9c),whilethepredictedforcefortheμ-SHdeviates fromthatmeasuredexperimentally.Thesimulatedforce–displacement oftheμ-SHincreasesmonotonically,whiletheexperimentalcurveex- hibitsaforce maximum.Theforcedifferencebetweenthesimulation andtheexperimentalresultsis4%atadisplacementof174𝜇m(theSwift modelpredictionis15.04Nwhile15.65Nwasmeasuredintheexperi- ment).Foradditionalvalidationofthehybridexperimental-numerical approach,wealsoverifiedtheagreementofthenumericalpredictions andtheexperimentalmeasurementsofthelogarithmicaxialstrainsat thecenterofthegagesectionoftheμ-NTandμ-CHspecimens(Figs.9e- f).

4.5. Comparisonofidentifiedmaterialproperties:macrovs.micro

Fig.10showsacomparisonoftherespectivestress-straincurvesob- tainedfromthemacro-andmicro-approaches.Thedifferencebetween thetwocurvesislessthan4%forstrainsofupto0.5.Giventhatthese macro-microvariationsaresmallerthanthevariationamongspecimens ofthesamekind,itisconcludedthatthemicro-testingtechniquepro- videsaviablealternativetomacro-testingasfarastheidentificationof strainhardeningisconcerned.

Recallthatthesimulationshadbeenstoppedwhentheapplieddis- placementattainedthecorrespondingexperimentalfracturedisplace- ment.TheFEsimulationgivesaccesstotheevolutionoftheequivalent strain,triaxialityandLodeangleparametersofalltestedconfigurations.

Fig.11aand11bdepicttheloadingpaths tofractureforthemacro- andmicro-cases;bothapproachesdeliversimilarevolutions.Theload- ingpathstofracturewerethenimportedintoaMATLABprogramto identifytheparametersoftheHosford-Coulombfracturemodel(byus- ingthederivative-freeminimizationalgorithm).Table5liststhefrac- turemodelparametersofthestudiedAPI-X65sheetspecimeninboth macroscopicandmicroscopictechniques;theoutputsareverysimilar.

The3Dfractureenvelopesrepresentingfracturestrainasafunctionof thestresstriaxialityandLodeparameterareillustratedinFig.11c(for thestandardmacroscopicapproach)andFig.11d(forthemicroscopic approach).Accumulationofequivalentstrainclosetotheplanestrain loading(𝜂 =0.577forisotropicmaterials)andshearloading(𝜂=0)

Fig.7. Actingforce-displacementinmacro-(solidblacklines)andmicro-specimens(solidredlines):(a)UT,(b)NT,(c)CH,(d)SH(Fanduforthemacro-results.

F𝜇andu𝜇forthemicro-results).(e)Stress-strainresponseofthematerialaccordingtothestandardmacroandnovelmicrouniaxialexperiments.

Table4

HardeningparametersoftheAPIX65pipelinesteel.

ratio Swift parameters Voce parameters

𝛼 A [ MPa ] n [ − ] 𝜀 0[ − ] k 0[ MPa ] Q [ MPa ] 𝛽[ − ] Standard 1.2 688.55 0.122 0.0010 348 186.1 25.58

Micro 1.0 676.9 0.118 0.0016 - - -

Fig.8. Comparisonofsimulationwithexperimentalresultsforstandardspecimens:(a)stress-straincurveformacro-UT,andforce-displacementcurvesfor(b) macro-NT,(c)macro-CH,(d)macro-SH.(e)Evolutionofthelocalstraininmacro-NT,(f)evolutionofthelocalstraininmacro-CH.

Table5

Hosford-Coulomb parameters of API X65 sheetspecimen.

a b c

Standard macro 1.55 1.21 0.001

Micro 1.43 1.18 0

areevidentlylowestinallloadingscenarios.Thehigheststrengthofthe materialoccursundertheuniaxialcompressionloading.Inspiteofhav- ingasimilartrendofstrainevolutionforbothexperimentalapproaches atallstudiedloadingpaths,thefracturestrainsattained frommicro-

experimentsaresystematicallylowerthanthoseattainedfrommacro- experiments.

Thesimilarityofthedeformationresponsesinthemacroscopicand miniaturizedspecimenssupportstheuseoftheminiaturizedspecimen tomeasurecontinuummechanicalpropertieswhenthereareatleast5 grainsthroughthegagethickness.However,theslightsystematicreduc- tioninthefailurestrainsobservedintheminiaturizedspecimencanbe speculatedtobeduetoadeleteriouseffectofasurfaceroughnessam- plitudethatissubstantialrelativetothespecimendimensions.Future workwiththeseminiaturizedspecimensshouldconsiderreductionof surfaceroughnessthroughpolishingofsurfacesornon-EDMmachining techniques,whilealsominimizinganyotheradversealterationofthe surfacefromfabricationplasticstrainsandensuringprecisemanufac- turingtolerances.

Fig.9. Comparisonofsimulationwithexperimentalresultsforstandardmicro-specimens:(a)stress-straincurveforμ-UT,andforce-displacementcurvesfor(b) μ-NT,(c)μ-CH,(d)μ-SH,(e)evolutionofthelocalstraininμ-NT,(f)evolutionofthelocalstraininμ-CH.

5. Discussion

Thepresent studyfocuses on theidentificationof a phenomeno- logicalfractureinitiationmodelforuncracked bodies.This approach providesanalternativetofracturemechanicstypeofexperimentsthat areconcernedwithmeasuringthefracturetoughnessusingSingleEdge NotchTension/Bending(SENT/SENB)specimensorwiththedetermina- tionofabsorbedimpactenergyusingCharpyspecimens(e.g.[49,50]).

AsdemonstratedbyKofianietal.[51],theresultsfromexperimentson SENTspecimenscanbesuccessfullypredictedthroughfiniteelement modelswhenusingphenomenologicalfracturemodels.Wethusexpect thatthepresentmicro-approachcanalsoserveasasubstituteforcon-

ventionalfractureexperimentsatthemacro-scale.Asfarastheeffect ofstrainrateisconcerned,futureresearchneedstodemonstratethat fracturemodels thatarecalibrated basedon highstrain ratemicro- experiments can alsopredict theresults from Charpyimpact experi- ments.

Inadditiontocharacterizingthematerialpropertygradientsthrough micro-experiments,theapplicationofnon-localplasticityandfracture models(e.g.[52,53])mayalsobeofinterestonthefuture.However,the gradientsinthemechanicalfieldsoftheproposedmicro-specimensmay betooweaktorevealnon-localeffects.Inviewofcalibratinggradient- sensitivematerialmodels,experimentswithcrackinitiationandcrack propagationundersmall-scaleyieldingandModeIplane-straincondi-

Fig.10. DerivedhardeningcurveofpipelinesteelalloyAPIX65usingmicro andmacroexperimentalmethods.

tions(e.g.[54])maybeneededinadditiontothemicro-testingprogram presentedinthepresentwork.Theintroductionofanon-localplastic- ityandwouldthenalsoallowfortheregularizationofmesh-sizeeffects associatedwithdamagemodeling.

6. Conclusions

The mainpurpose of the present research is to demonstrate (i) thatitistechnically-feasibletodaytoperform experimentsonmicro- specimens extracted from structures, and (ii) that the plasticity ob- tainedfrommicro-experimentsmatchthoseobtainedfromconventional macro-experiments.Atthemacro-level,weperformalsobasicplasticity andfracturetestingprogram tocharacterize thelargestrainharden- ingandstress-statedependentfractureresponseofpipelinesteel.The portfolioincludeduniaxialtension,centralholetension,notchedten- sion,andflatshearspecimens.Allmacro-specimensfeaturedauniform thicknessof2mmwithgagesectionwidthsofseveralmillimeters.For theexperimentsatthemicro-level,thedimensionsofallspecimentypes weredownscaledbyafactorof20.Inotherwords,themicro-specimens wereonly100𝜇mthick,andafewhundredmicrometerswide.Withan averagegrain sizeof 30𝜇m,thespecimensfeaturedstillatleast four BCCgrains(ferrite)alongthethicknessdirection,buttenormoreinthe planardirection.Themicro-experimentswereperformedunderanopti- calmicroscopeusingacustom-madeloadingdevice.Thedisplacement andsurfacestrainfieldsinboththemicro-andmacro-experimentswere determinedusingplanardigitalimagecorrelation.

Thehybridexperimental-numericalanalysisofallexperimentalre- sultsrevealedthat almostthesamematerialplasticityproperties are obtained withboththemacro-andmicro-approaches.Themaximum differenceintheidentifiedstress-straincurvesfortensilestrainsofupto 50%islessthan4%instress.Asfarastheductilityisconcerned,slightly lowerfracturestrainsareobservedinthemicro-experiments.Forexam-

Fig.11. Comparisonofacriticalelementin(a)macro-and(b)micro-experimentsasafunctionofthestresstriaxiality.TheHosford-Coulombfracturelocusfor proportionalloadingasafunctionofthestressstateasidentifiedfrom(c)macro-,(d)micro-fractureexperiments.

ple,forcentralholetension,themacro-experimentssuggestedafracture strainof1.19whilethevalueobtainedfromthemicro-experimentsis only1.12.Overall,thedifferencesaresmallandfallintotherangeof uncertaintyoftherespectiveexperiments.Consequently,theidentified Hosford-Coulombfractureinitiationmodelparametersturnedouttobe similaraswell,therebyvalidatingthemicro-experimentapproachasa viablealternativetoconventionalmacro-experiments.Itis concluded thattheproposedmicro-testingtechniqueprovidesausefulmeansto identifythemechanicalpropertiesofmaterialsingradedandsmall-scale structuressuchasthin-walledlinepipe,weldments,castings,additively- manufacturedstructures, micro-electronics (including batteries), and micro-sizebiomedicalimplants.

DeclarationofCompetingInterest

Theauthorsdeclarethattheyhavenoknowncompetingfinancial interestsorpersonalrelationshipsthatcouldhaveappearedtoinfluence theworkreportedinthispaper.

Acknowledgements

Thepartial financialsupport of the MIT/ETH Industrial Fracture Consortiumisgratefullyacknowledged.SpecialthanksareduetoProf.

Wierzbicki(MIT)forvaluablediscussions.AlsothankstoTomasBeerli, Dr.ThomasWesner,Dr. ColinBonatti,Dr.ThomasTancogne-Dejean, andMs.MariannaDiamantopouloufortheirhelpwiththemicro-tension experiments.

References

[1] Oliver WC, Pharr GM. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J Mater Res 1992;7(6):1564–83. doi: 10.1557/JMR.1992.1564 .

[2] Giannakopoulos AE , Suresh S . Determination of elastoplastic properties by instru- mented sharp indentation. Scr Mater 1999;40(10):1191–8 .

[3] Luo J, Zhao Z, Shen J, Zhang C. Elastic–plastic analysis of ultrafine-grained Si2N2O–

Si3N4 composites by nanoindentation and finite element simulation. Ceram Int 2014;40(5):7073–80. doi: 10.1016/j.ceramint.2013.12.039 .

[4] Wang M, Wu J, Hui Y, Zhang Z, Zhan X, Guo R. Identification of elastic-plastic properties of metal materials by using the residual imprint of spherical indentation.

Mater Sci Eng 2017;679:143–54. doi: 10.1016/j.msea.2016.10.025 .

[5] Sharpe WN, Yuan B, Edwards RL. A new technique for measuring the me- chanical properties of thin films. J Microelectromech Syst 1997;6(3):193–9.

doi: 10.1109/84.623107 .

[6] Chasiotis I, Knauss WG. Mechanical properties of thin polysilicon films by means of probe microscopy. In: Materials and device characterization in microma- chining, 3512. International Society for Optics and Photonics; 1998. p. 66–75.

doi: 10.1117/12.324072 .

[7] Espinosa HD, Prorok BC, Fischer M. A methodology for determining mechanical properties of freestanding thin films and MEMS materials. J Mech Phys Solids 2003;51(1):47–67. doi: 10.1016/S0022-5096(02)00062-5 .

[8] Zhu Y, Espinosa HD. An electromechanical material testing system for in situ electron microscopy and applications. Proc Natl Acad Sci 2005;102(41):14503–8.

doi: 10.1073/pnas.0506544102 .

[9] Gravier S , Coulombier M , Safi A , André N , Boé A , Raskin JP , Pardoen T . New on-chip nanomechanical testing laboratory-applications to aluminum and polysilicon thin films. J Microelectromech Syst 2009;18(3):555–69 .

[10] Colla MS, Wang B, Idrissi H, Schryvers D, Raskin JP, Pardoen T. High strength-ductility of thin nanocrystalline palladium films with nanoscale twins:

on-chip testing and grain aggregate model. Acta Mater 2012;60(4):1795–806.

doi: 10.1016/j.actamat.2011.11.054 .

[11] Bhaskar U, Passi V, Houri S, Escobedo-Cousin E, Olsen SH, Pardoen T, Raskin JP.

On-chip tensile testing of nanoscale silicon free-standing beams. J Mater Res 2012;27(3):571–9. doi: 10.1557/jmr.2011.340 .

[12] Li X, Kasai T, Nakao S, Tanaka H, Ando T, Shikida M, Sato K. Measurement for fracture toughness of single crystal silicon film with tensile test. Sens Actuators, A 2005;119(1):229–35. doi: 10.1016/j.sna.2003.10.063 .

[13] Xiang Y, Chen X, Vlassak JJ. Plane-strain bulge test for thin films. J Mater Res 2005;20(9):2360–70. doi: 10.1557/jmr.2005.0313 .

[14] Haque MA, Saif MT. A review of MEMS-based microscale and nanoscale tensile and bending testing. Exp Mech 2003;43(3):248–55. doi: 10.1007/BF02410523 . [15] Mine Y, Hirashita K, Takashima H, Matsuda M, Takashima K. Micro-tension be-

haviour of lath martensite structures of carbon steel. Mater. Sci. Eng. 2013;560:535–

44. doi: 10.1016/j.msea.2012.09.099 .

[16] Tsuchiya T, Hirata M, Chiba N, Udo R, Yoshitomi Y, Ando T, Sato K, Takashima K, Higo Y, Saotome Y, Ogawa H. Cross comparison of thin-film tensile-testing meth- ods examined using single-crystal silicon, polysilicon, nickel, and titanium films. J Microelectromech Syst 2005;14(5):1178–86. doi: 10.1109/JMEMS.2005.851820 .

[17] Ran JQ, Fu MW. A hybrid model for analysis of ductile fracture in micro- scaled plastic deformation of multiphase alloys. Int J Plast 2014;61:1–6.

doi: 10.1016/j.ijplas.2013.11.006 .

[18] Wang X, Xu J, Shan D, Guo B, Cao J. Effects of specimen and grain size on electrically-induced softening behavior in uniaxial micro-tension of AZ31 magnesium alloy: experiment and modeling. Mater. Des. 2017;127:134–43.

doi: 10.1016/j.matdes.2017.04.064 .

[19] Shen Y, Morgeneyer TF, Garnier J, Allais L, Helfen L, Crépin J. Three-dimensional quantitative in situ study of crack initiation and propagation in AA6061 aluminum alloy sheets via synchrotron laminography and finite-element simulations. Acta Mater 2013;61(7):2571–82. doi: 10.1016/j.actamat.2013.01.035 .

[20] Morgeneyer TF, Taillandier-Thomas T, Helfen L, Baumbach T, Sinclair I, Roux S, Hild F. In situ 3-D observation of early strain localization during failure of thin Al alloy (2198) sheet. Acta Mater 2014;69:78–91. doi: 10.1016/j.actamat.2014.01.033 . [21] Li J, Xu J, Guo B, Shan D, Langdon TG. Shear fracture mechanism in micro-tension of an ultrafine-grained pure copper using synchrotron radiation X-ray tomography.

Scr Mater 2017;132:25–9. doi: 10.1016/j.scriptamat.2017.01.021 .

[22] Ran JQ, Fu MW. A hybrid model for analysis of ductile fracture in micro- scaled plastic deformation of multiphase alloys. Int J Plast 2014;61:1–6.

doi: 10.1016/j.ijplas.2013.11.006 .

[23] Bonatti C, Mohr D. Anisotropic viscoplasticity and fracture of fine grained metal- lic aluminum foil used in Li-ion batteries. Mater Sci Eng 2016;654:329–43.

doi: 10.1016/j.msea.2015.11.048 .

[24] Zhu J, Zhang X, Luo H, Sahraei E. Investigation of the deformation mecha- nisms of lithium-ion battery components using in-situ micro tests. Appl Energy 2018;224:251–66. doi: 10.1016/j.apenergy.2018.05.007 .

[25] de Vasconcelos LS, Xu R, Zhao K. Operando nanoindentation: a new platform to measure the mechanical properties of electrodes during electrochemical reactions.

J Electrochem Soc 2017;164(14):A3840–7. doi: 10.1149/2.1411714jes .

[26] de Vasconcelos LS, Sharma N, Xu R, Zhao K. In-Situ nanoindentation measurement of local mechanical behavior of a Li-ion battery cathode in liquid electrolyte. Exp Mech 2019;59(3):337–47. doi: 10.1007/s11340-018-00451-6 .

[27] Sheidaei A, Xiao X, Huang X, Hitt J. Mechanical behavior of a battery separator in electrolyte solutions. J Power Sources 2011;196(20):8728–34.

doi: 10.1016/j.jpowsour.2011.06.026 .

[28] Cannarella J, Liu X, Leng CZ, Sinko PD, Gor GY, Arnold CB. Mechanical prop- erties of a battery separator under compression and tension. J Electrochem Soc 2014;161(11):F3117–22. doi: 10.1149/2.0191411jes .

[29] Dobi D , Junghans E . Determination of the tensile properties of specimens with small dimensions. Kovine Zlitine Tehnologije(Slovenia) 1999(6):451–7 .

[30] Rodríguez C , Cabezas JG , Cárdenas E , Belzunce FJ , Betegón C . Mechanical prop- erties characterization of heat-affected zone using the small punch test. Weld J 2009;88:188–92 .

[31] Vega OE, Hallen JM, Villagomez A, Contreras A. Effect of multiple repairs in girth welds of pipelines on the mechanical properties. Mater Charact 2008;59(10):1498–

507. doi: 10.1016/j.matchar.2008.01.011 .

[32] Zhang X, Gao H, Zhang X, Yang Y. Effect of volume fraction of bainite on microstruc- ture and mechanical properties of X80 pipeline steel with excellent deformability.

Mater. Sci. Eng. 2012;531:84–90. doi: 10.1016/j.msea.2011.10.035 .

[33] Gao K, Yu F, Pang X, Zhang G, Qiao L, Chu W, Lu M. Mechanical properties of CO2 corrosion product scales and their relationship to corrosion rates. Corros Sci 2008;50(10):2796–803. doi: 10.1016/j.corsci.2008.07.016 .

[34] Paredes M, Zelenak P, Wierzbicki T. A Numerical Study on Crack Growth Re- sistance Curve of X70 Steels. ASME 2016 Pressure Vessels and Piping Con- ference. American Society of Mechanical Engineers Digital Collection; 2016.

doi: 101115/PVP2016-63911 .

[35] Paredes M, Wierzbicki T, Zelenak P. Prediction of crack initiation and propagation in X70 pipeline steels. Eng Fract Mech 2016;168:92–111.

doi: 10.1016/j.engfracmech.2016.10.006 .

[36] Barsoum I, Faleskog J. Rupture mechanisms in combined tension and shear —Experiments. Int J Solids Struct 2007;44(6):1768–86.

doi: 10.1016/j.ijsolstr.2006.09.031 .

[37] Bai Y, Wierzbicki T. Application of extended Mohr–Coulomb criterion to ductile fracture. Int J Fract 2010;161(1):1. doi: 10.1007/s10704-009-9422-8 .

[38] Danas K, Castañeda PP. Influence of the Lode parameter and the stress triaxiality on the failure of elasto-plastic porous materials. Int J Solids Struct 2012;49(11- 12):1325–42. doi: 10.1016/j.ijsolstr.2012.02.006 .

[39] Dunand M, Mohr D. Effect of Lode parameter on plastic flow localization after pro- portional loading at low stress triaxialities. J Mech Phys Solids 2014;66:133–53.

doi: 10.1016/j.jmps.2014.01.008 .

[40] Dunand M, Mohr D. Hybrid experimental–numerical analysis of basic ductile fracture experiments for sheet metals. Int J Solids Struct 2010;47(9):1130–43.

doi: 10.1016/j.ijsolstr.2009.12.011 .

[41] Gorji M, Berisha B, Hora P, Barlat F. Modeling of localization and fracture phe- nomena in strain and stress space for sheet metal forming. Int J Mater Form 2016;9(5):573–84. doi: 10.1007/s12289-015-1242-y .

[42] Roth CC, Mohr D. Determining the strain to fracture for simple shear for a wide range of sheet metals. Int J Mech Sci 2018;149:224–40.

doi: 10.1016/j.ijmecsci.2018.10.007 .

[43] Gorji MB, Mohr D. Predicting shear fracture of aluminum 6016-T4 during deep drawing: Combining Yld-2000 plasticity with Hosford–Coulomb fracture model. Int J Mech Sci 2018;137:105–20. doi: 10.1016/j.ijmecsci.2018.01.008 .

[44] Gorji MB, Mohr D. Micro-tension and micro-shear experiments to charac- terize stress-state dependent ductile fracture. Acta Mater 2017;131:65–76.

doi: 10.1016/j.actamat.2017.03.034 .

![Fig. 2. Drawings of (a) standard macro specimens, (b) novel micro specimens; all units are in [mm]](https://thumb-eu.123doks.com/thumbv2/1library_info/3910129.1526207/4.892.125.768.84.314/drawings-standard-macro-specimens-novel-micro-specimens-units.webp)