Research Collection

Doctoral Thesis

Wood Modification with Proteins for the Development of Novel Functional Membranes

Author(s):

Goldhahn, Christian Publication Date:

2020-05

Permanent Link:

https://doi.org/10.3929/ethz-b-000419271

Rights / License:

In Copyright - Non-Commercial Use Permitted

This page was generated automatically upon download from the ETH Zurich Research Collection. For more information please consult the Terms of use.

ETH Library

DISS. ETH NO. 26806

Wood Modification with Proteins for the Development of Novel Functional Membranes

A thesis submitted to attain the degree of DOCTOR OF SCIENCES

(Dr. sc. ETH Zurich)

presented by

Christian Goldhahn

Master of Science, University of Bayreuth

born on 21.07.1990 citizen of Germany

accepted on the recommendation of

Prof. Dr. Ingo Burgert, ETH Zürich, examiner Dr. Munish Chanana, Swiss Wood Solutions AG, co-examiner

Prof. Dr. Tobias Kraus, Leibniz Institute for New Materials Saarbrücken, co-examiner Prof. Dr. Markus Linder, Aalto University, co-examiner

Dr. Mark Schubert, Empa Dübendorf, co-examiner

2020

i

Abstract

Materials have to become more sustainable to comply with a future carbon-neutral and eco-friendly society. Hence, natural resources as feedstock for the production of green materials are an emerging topic in current research. Wood is a natural material with a hierarchical anisotropic structure, which provides beneficial properties for the development of functional materials. Therefore, wood materials science has recently grown to an intensely investigated research field. It comprises the development of novel functional hybrid and composite materials by using wood and modifying its structure.

Wood’s anisotropic porosity makes the material particularly suited for an application as membrane, as it allows a directed flow of liquids through the structure. Hence, multiple wood-based membranes with diverse functions have been investigated. However, the chemical modifications used to synthesize these wood-based functional materials are often unsustainable and non-eco-friendly.

As a sustainable alternative, the combination of wood with proteins for the development of green functional membranes is investigated in this work. Enzymes were immobilized in the wood structure to create wood-based biocatalytic membranes. This was achieved by a gold-nanoparticle- mediated adsorption process, which was first developed on cellulose fibers as a model system.

Subsequently, the process was transferred to the wood structure. The resulting hybrid materials showed biocatalytic activity, multifold reusability, and could be applied for continuous-flow biocatalysis. Their biocatalytic activity was investigated and compared to that of free enzymes.

Moreover, the goal of this work was to further develop the biocatalytic membrane to become a biocatalytic membrane reactor. In addition to the catalytic function, tunable flow-through behavior of the membrane is a necessary characteristic in this regard to achieve an optimization of the membrane efficiency. The polypeptide gelatin was used to impart such characteristics to the wood structure. This natural hydrogel was infiltrated into the wood structure, resulting in wood-gelatin composites. The water-penetration behavior of the composites differed from native wood, due to micro-structures formed by the gelatin inside the wood pores. The underlying structure-property- relationships were investigated thoroughly. A particular focus was the composites’ flow-through behavior when using them as a membranes. This behavior was found to be tunable by varying the gelatin loading as well as the sample thickness.

The developed modification approaches rely on straightforward aqueous processes without the use of harmful chemicals. Moreover, the yielded wood-based hybrids and composites are largely biodegradable and offer good recycling perspectives. Hence, they can be considered as green alternatives to conventional functional membranes.

This thesis shows that the modification of wood with functional biomolecules has great potential for future material development. The production of various entirely bio-based and biodegradable functional materials is conceivable by the smart combination of hierarchical wood-based scaffolds and biomolecular functions. Such materials can make a substantial contribution to the necessary transformation of our society towards a sustainable future.

|iii

Zusammenfassung

Materialien müssen zukünftig nachhaltiger werden, um den Wandel zu einer CO2-neutralen und umweltverträglichen Gesellschaft zu unterstützen. Daher widmet sich die Wissenschaft verstärkt der Erforschung natürlicher Ressourcen als Ausgangsmaterial für „grüne Materialien“. Holz ist ein natürlicher Werkstoff, der aufgrund seiner komplexen hierarchischen Struktur richtungsabhängige Eigenschaften besitzt. Damit liefert Holz vielversprechende Voraussetzungen um als Basis für die Entwicklung funktioneller Materialien zu dienen. Das Feld der holzbasierten Materialwissenschaft erhält daher regen Zulauf. Es umfasst die Erforschung neuartiger funktionaler Hybrid- und Kompositmaterialien auf der Basis von Holz. Bei einigen dieser Materialien handelt es sich um Membranen, da Holz im Wesentlichen aus axial ausgerichteten Poren besteht, die den gerichteten Durchfluss von Flüssigkeiten erlauben, und somit grundsätzlich gut für Anwendungen in Membranprozessen geeignet ist. Zahlreiche holzbasierte Membranen mit unterschiedlichsten Funktionen wurden daher bereits entwickelt.

Die Herstellung solcher holzbasierten funktionalen Materialien erfolgt dabei zumeist durch chemische Modifikationen der Holzstruktur, durch die Eigenschaften des Holzes verändert und neue Funktionalitäten eingebracht werden können. Allerdings sind die chemischen Verfahren, die dafür angewendet werden, oft nicht nachhaltig oder sogar umweltschädlich.

Als eine Alternative zu diesen konventionellen Methoden wird in dieser Arbeit die Modifikation von Holz mit Proteinen untersucht, mit dem Ziel, umweltverträgliche, funktionelle Membranmaterialien herzustellen. Enzyme wurden in der Holzstruktur immobilisiert, um eine biokatalytisch aktive Membrane herzustellen. Dafür wurden zuerst Goldnanopartikel in das Material eingebracht, an die anschliessend die Enzyme adsorbiert wurden. Der Prozess wurde zunächst an Zellulosefasern als Modellsystem entwickelt. Anschliessend wurde er auf das komplexere Material Holz übertragen. Die hergestellten Hybridmaterialien zeigten katalytische Aktivität und konnten mehrfach wiederverwendet werden. Ausserdem war es möglich, sie als Membranreaktoren für kontinuierliche Biokatalyse im Durchfluss zu verwenden. Ihre biokatalytische Aktivität wurde eingehend untersucht und mit der von freien Enzymen verglichen.

Darüber hinaus lag der Fokus dieser Arbeit darauf, die entwickelten Membranen zu einem biokatalytischen Membranreaktor weiterzuentwickeln. Neben der biokatalytischen Aktivität bedarf es dazu eines regelbaren Durchflussverhaltens der Membran. Um der Holzstruktur diese Eigenschaft zu verleihen, wurde das Polypeptid Gelatine in die Holzstruktur eingebracht. Dieses natürliche Hydrogel bildet Mikrostrukturen in den Holzporen, wodurch sich die Membraneigenschaften des Komposits im Vergleich zu unbehandeltem Holz verändern. Die entsprechenden Struktur-Eigenschaft-Beziehungen wurden ausführlich untersucht, wobei der

Fokus auf der Untersuchung der Durchflusseigenschaft des Materials lag. Die Resultate zeigen, dass der Durchfluss sowohl von der Menge an Gelatine, die in die Holzstruktur gebracht wurde, als auch von der Probendicke abhängt.

Die entwickelten Methoden können mit geringem Aufwand im wässrigen Medium durchgeführt werden und kommen ohne den Einsatz schädlicher Chemikalien aus. Ausserdem sind die entwickelten Komposite grösstenteils bioabbaubar und können gut recycelt werden. Sie können daher als umweltfreundliche Alternativen zu herkömmlichen funktionellen Membranen betrachtet werden.

Zusammenfassend lässt sich sagen, dass diese Arbeit das Potential aufzeigt, welches die Kombination von Holz und Biomolekülen für die Herstellung neuartiger Materialien mit sich bringt. Es bietet sich die Möglichkeit, eine Vielzahl von vollkommen biobasierten und bioabbaubaren Funktionsmaterialien herzustellen, indem die holzbasierte Gerüstsubstanz mit den Funktionalitäten, die Biomoleküle bieten, kombiniert wird.

|v

Table of Content

Abstract ... i

Zusammenfassung ... iii

Table of Content ... v

1. Introduction ... 1

1.1. Motivation and Objectives ... 1

1.2. Outline of the thesis ... 4

1.3. The material wood ... 5

1.3.1. Wood structure ... 5

1.3.2. The hardwoods beech and poplar ... 10

1.3.3. Wood-based functional materials ... 12

1.4. Proteins ... 15

1.4.1. Protein structure... 15

1.4.2. Enzymes ... 16

1.4.2.1. Enzymatic biocatalysis ... 17

1.4.2.2. Enzyme immobilization ... 20

1.4.2.2.1. Immobilization scaffolds and methods ... 20

1.4.2.2.2. Continuous-flow biocatalysis ... 22

1.4.2.2.3. Wood as a green scaffold for enzyme immobilization ... 23

1.4.3. Gelatin ... 24

1.5. Wood bio-hybrid materials ... 25

1.5.1. Biomolecules for wood gluing and coating ... 25

1.5.2. Wood bio-hybrid membranes ... 26

1.6. Characterization Methods ... 28

2. Publications ... 31

2.1. Nanoparticle-Mediated Enzyme Immobilization on Cellulose Fibers: Reusable Biocatalytic Systems for Cascade Reactions ... 32

2.1.1 Abstract ... 32

2.1.2. Introduction ... 33

2.1.3. Results and Discussion ... 35

2.1.4. Conclusion ... 44

2.1.5. Materials and Methods ... 45

2.1.6. Acknowledgements ... 47

2.1.7. References ... 48

2.1.8. Supplementary Information ... 51

2.2. Enzyme Immobilization Inside the Porous Wood Structure: a Natural Scaffold for Continuous-Flow Biocatalysis ... 53

2.2.1. Abstract ... 53

2.2.2. Introduction ... 54

2.2.3. Results and Discussion... 56

2.2.4. Conclusion and Outlook... 67

2.2.5. Materials and Methods ... 69

2.2.6. Acknowledgements ... 71

2.2.7. References ... 71

2.2.8. Supplementary Information ... 77

2.3. Wood-Gelatin Bio-Composite Membranes with Tunable Flux ... 79

2.3.1. Abstract ... 79

2.3.2. Introduction ... 80

2.3.3. Results and Discussion... 82

2.3.4. Conclusion and Outlook... 91

2.3.5. Materials and Methods ... 92

2.3.6. Acknowledgements ... 93

2.3.7. References ... 94

2.3.8. Supplementary Information ... 97

3. General Discussion ... 100

3.1. Wood-based biocatalytic membranes ... 101

3.2. Wood-gelatin composite membranes ... 107

3.3. Wood-based biocatalytic membrane reactor ... 109

4. Outlook ... 111

Acknowledgements ... 113

Curriculum vitae ... 114

5. References for chapters 1,3, and 4 ... 116

Motivation and Objectives | 1

1. Introduction

1.1. Motivation and Objectives

Climate change, environmental pollution, and resource scarcity are some of the main challenges of our time. All of them are caused by humanity’s unsustainable way of living, which relies heavily on fuel-based energy and products, as well as the depletion of natural resources. To tackle these problems, the United Nations member states adopted the 2030 Agenda for Sustainable Development, or commonly referred to as Sustainable Development Goals, in 2015.1 One of these Sustainable Development Goals is the sustainable consumption and production of goods. It comprises the efficient use of natural resources as well as reducing the impact of material production on the environment.2

Materials that are based on re-growing biological resources are a key element to reach this goal.

They exhibit a CO2-neutral life cycle and are often biodegradable, reducing their environmental impact. Hence, bio-based biodegradable materials are an essential building block for the necessary transformation of our fuel-based economy to a sustainable circular economy.3

A prerequisite for more sustainable materials, however, is not only the use of renewable resources, but also a sustainable production process.4 Green chemistry has to become the standard of future material production. This comprises avoiding of waste products, a low energy consumption, usage of safe solvents like water, and biodegradability of the products.5

The production of functional materials under these conditions is particularly challenging. Nature itself, though, can serve as a role model when it comes to the formation of complex functional materials.6 Various sophisticated structures, which fulfil a plethora of functions, evolved over the course of time in the living world.7 Amazingly, natural functional materials can be found at various length scales from enzymes as molecular machines, over nano- and micro-structured surfaces as in lotus leafs or gecko feet, up to almost macroscopic entities like sensory hairs.8-9 Hierarchical materials, such as nacre or bone, bridge all these length scales and realize outstanding macroscopic properties based on molecular-sized components that are assembled to well defined microstructures.10-11 The use of such hierarchical materials as a natural resource can render tedious bottom-up assembly of synthetic building blocks redundant. Therefore, it is a promising strategy for the development of novel green functional materials.12-13

Wood is a complex hierarchical natural material. Its anisotropic composition manifests over multiple levels of the length scale. It starts with oriented cellulose macromolecules on the molecular level, which form oriented nano-sized fibers, and continues with unidirectional pores on the micro- level, forming an anisotropic tissue with unique anisotropic properties on the macroscale. This sophisticated structure provides the necessary mechanical as well as morphological properties to

make wood a promising resource for the production of sustainable functional materials.

Consequently, various wood-based functional materials have been presented over the last years.

They combine wood’s unique hierarchical structure with functional agents that are imparted by chemical modification. The resulting hybrids can realize manifold functions and serve for diverse applications.14-16

However, the underlying treatments mostly disregard the principles of green chemistry. They rely on the modification of wood with fuel-based compounds or methods that require solvent-based chemistry. In addition, the resulting wood-based hybrids exhibit a problematic end of lifetime, as their constituents can hardly be recovered or recycled. Consequently, the use of wood as a natural resource is not necessarily sufficient to create a green, sustainable, and applicable functional material. Hence, more sustainable wood modification approaches are required.

The use of proteins is one possibility to realize green wood modifications. These biological macromolecules are abundant in nature, where they realize a plethora of functions in an aqueous environment under moderate conditions. Their abilities comprise biocatalysis, stimuli-responsive behavior, molecular transport, molecular motion, and many more.17 The key to this versatility is their hierarchical composition. While all proteins are composed from the same chemical building blocks, the amino acids, their hierarchical structure defines their characteristics and functions.

Therefore, proteins are a tremendously diverse class of natural molecules, which offer huge potential for the use in green chemistry in general and for wood materials science in particular.

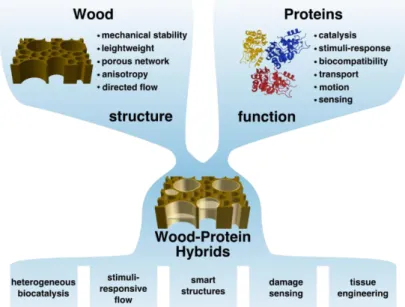

Novel eco-friendly wood-protein hybrids are conceivable by the combination of wood’s unique hierarchical structure and the various functions offered by proteins (Figure 1).

Figure 1: Schematic illustration of the combination of wood and proteins. Wood-protein hybrids can combine the unique wood structure with the protein functions. Hence, they have potential for various applications.

Motivation and Objectives | 3

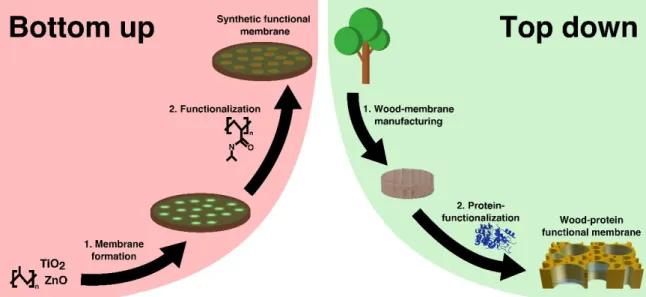

One particular field in which the synergies between wood and proteins can be utilized are functional membranes. Wood is well suited as a resource for membrane production as its anisotropic porosity readily accounts for directed water transport along the tree’s axial direction. Therefore, the development of wood-based membranes has intensified lately.18-21 However, more eco-friendly processes are required in this field as well. Furthermore, these investigations strongly focus on the proof of concept of chemically modifying wood to impart novel functionalities to its structure.20-21 So far, less attention has been put on the membrane performance itself, which depicts properties like its flux and pressure drop. These characteristics, however, are very important when it comes to the implementation of the membrane in an application process.

The goal of this work is to develop a wood-based bio-hybrid material that is suited for an application as a functional membrane. To achieve this objective, it is necessary to impart both a valuable function and control over the membrane’s flow-through behavior. These challenges can be tackled by the use of proteins as discussed in the following.

An interesting function offered by proteins is enzymatic biocatalysis. Enzymes offer high catalytic activity at moderate reaction conditions. Hence, they can function as a central building block for future sustainable industrial processes.22-23 Combining their biocatalytic function with the membrane-like structure of wood is a promising strategy to yield biocatalytic membrane reactors.

Besides the catalytic function, controllable flux is a necessary requirement for the creation of a fully functional membrane reactor. Hence, wood’s natural porosity has to be modified to allow tuning of its water-permeability. The polypeptide gelatin can be used to create a wood-based membrane with such tunable characteristics. This natural hydrogel is derived from the structural protein collagen.

It provides temperature-responsive solubility in water with film-building properties upon cooling.24 Hence, its combination with wood could result in selective modification of the porosity, resulting in tunable permeability of the yielded bio-hybrid membrane. Even the introduction of temperature- responsive permeability to the wood structure is conceivable due to gelatin’s thermoresponsive solubility.

The development of the wood bio-hybrid materials as well as their characterization and application are shown and discussed in this thesis. There are four central objectives of this work to achieve the overall goal of developing a wood-protein-based functional biocatalytic membrane reactor:

1) Development of a green approach for the immobilization of enzymes on a natural model scaffold

2) Transfer of this approach to wood for a successful enzyme immobilization on its structure and the use of the resulting hybrid as a catalytically active membrane for continuous-flow biocatalysis

3) Gain control over the flow-through behavior of wood-based membranes by bio- modification of wood with gelatin, aiming in functional membranes with tunable and stimuli-responsive flux

4) Combine the biocatalytic function with the tunable flux to develop a fully functional biocatalytic membrane reactor

By combining these objectives, a green functional material can be developed that bridges the gap from a functional membrane to an applicable smart material, which offers control over its properties and hence facilitates its implementation in commercial processes.

1.2. Outline of the thesis

The main part of this cumulative thesis are three journal articles. They describe the combination of the natural products wood and cellulose with proteins to develop novel functional materials for membrane applications. These articles are accompanied by a general introduction, a discussion, and an outlook.

The introduction provides the background for the materials used in this thesis, namely wood, enzymes, and gelatin, as well as the general concept for their combination. The structure of wood is described from the molecular level to the macroscale in chapter 1.3.1. with a particular focus on its anisotropic porosity and the application potential as a membrane material. The subsequent chapter provides an introduction of the wood species beech and poplar, which were used in this work (chapter 1.3.2.). Thereafter, in chapter 1.3.3., an overview over wood-based functional materials, in particular functional membranes, is presented.

The following section of the introduction is about proteins as biological functional materials. After a general introduction of proteins regarding their chemical composition and structure in chapter 1.4.1., enzymatic biocatalysis and enzyme immobilization are described in chapter 1.4.2..

Thereafter, the protein-based natural hydrogel gelatin is introduced. Chapter 1.4.3. presents its structure and composition, as well as its structure-forming and temperature-responsive gelation properties.

In chapter 1.5., the concept of wood-bio hybrids is presented. The chapter gives an overview over traditional combinations of wood with biomolecules for gluing and coating. Furthermore, the novel approach of modifying bulk wood with biomolecules for the production of functional membranes is presented.

In the last chapter of the introduction (1.6.), the characterization methods that were used in the course of this work are presented. The chapter comprises a list of established methods, which are

The material wood | 5

described in detail in the journal articles. Moreover, a particular focus is put on the set-up that was developed to execute flow-through experiments with wood-based membranes.

The main part of the thesis (chapter 2) consists of three journal articles. The first one, “Nanoparticle- Mediated Enzyme Immobilization on Cellulose Fibers: Reusable Biocatalytic Systems for Cascade Reactions”, presents the immobilization of enzyme on cellulose fibers. The cellulose fibers served as a model system for the development of the immobilization method before transferring them to the more complex wood structure. The latter is presented in chapter 2.2., which consists of the article “Enzyme Immobilization Inside the Porous Wood Structure: a Natural Scaffold for Continuous Flow Biocatalysis”. It shows the production of a biocatalytic flow-through reactor from wood and enzymes as well as the characterization of the system. The final article “Wood-Gelatin Bio-Composite Membranes with Tunable Flux”, which makes up chapter 2.3., introduces the production of a wood-gelatin composite, which can be applied as a membrane material with tunable flux.

The final part of the thesis provides a general discussion of the results presented in this thesis (chapter 3) and future research perspectives (chapter 4).

1.3. The material wood

Wood has been used globally as a structural material for the building of houses and furniture for thousands of years. Generally, it is easy to process and provides good mechanical properties while at the same time being relatively lightweight. This rather unique property profile originates from its hierarchical structure, which is present over multiple length scales from aligned macromolecules up to unidirectional micropores.25

Moreover, this complex structure with its unique properties has inspired plenty of materials science research activities, which target the utilization of wood beyond the common applications. A multitude of wood-based hybrids and composites have been created as green materials in recent years. These materials are based on the hierarchical structure of wood and are yielded by various chemical modifications.14-16 Therefore, to advance the field of wood materials science, it is essential to have a profound knowledge about the wood structure, its chemical composition, as well as possible modification techniques.16

1.3.1. Wood structure

Wood as it is discussed and used in this work, refers to the xylem of the trunk of a tree. The xylem is the inner part of the trunk and makes up its biggest part (Figure 2). In the living tree, it provides mechanical stability, is responsible for water transport from the roots to the leaves and serves as a

storage for biochemical compounds. For many wood species, it is divided into two parts, the inner heartwood and the outer sapwood. In the sapwood region, water transport takes place. The parenchyma cells in this region are still alive and produce metabolic products. The heartwood region, in contrast, consists exclusively of dead cells and the water transport function of the axial tissue has been terminated. To the outside, the xylem is surrounded by the vascular cambium, which is a thin layer that produces new cells, leading to the growth in girth of the tree. Next to the vascular cambium towards the outside of the trunk is the phloem, a layer of living cells responsible for nutrient transport. Adjacent to the phloem is the outermost layer of the tree, the bark, which protects the tree against environmental influences, such as fire, UV-light, and microorganisms.26-27

Figure 2: Schematic illustration of the structural components of a tree’s trunk.28

Wood is a natural fiber-composite. On the molecular level, it is mainly built up from three biomacromolecules: cellulose, lignin, and hemicelluloses (Figure 3). Other chemical components that are present in wood are non-structural elements, called extractives. Cellulose is a polysaccharide, which consists of D-glucose monomers that are ß-(1,4)-linked to each other. Hence, the repeating unit in the cellulose macromolecules is a cellobiose unit (Figure 3a). In wood this polymer forms aligned fibrils, which assemble to fibril aggregates. These are embedded in a matrix of lignin and hemicelluloses. In contrast to the semicrystalline cellulose, lignin is an amorphous polymer, which consists of various aromatic building blocks. Its main building blocks are shown in Figure 3b. In the wood structure, these polyphenolic monomers form the crosslinked polymer lignin. The composition is very heterogeneous and differs between wood species. Besides forming the matrix in the cell walls, lignin is the main component of the middle lamella, which connects neighboring cells. Hemicelluloses are another part of the fiber-surrounding matrix and act as a linker between the cellulose fiber aggregates and the lignin matrix.26 Hemicellulose is a collective

The material wood | 7

term for polysaccharides of varying combinations of several monomeric building blocks (Figure 3c). Typical building blocks are xylose, arabinose, and mannose. In addition, several other sugar molecules can be incorporated in the hemicellulose structure. Hemicelluloses exhibit an amorphous structure, likewise lignin.26, 29-31

Figure 3: Illustration of the chemical structures of wood’s structural building blocks. (a) cellobiose repeating unit of cellulose macromolecules, (b) monomeric building blocks of lignin (I: coniferyl alcohol, II: sinapyl alcohol, III: coumaryl alcohol), (c) exemplary molecular motif of hemicellulose.

Wood’s unique properties, though, are not mainly based on the chemical composition of its building blocks, but rather on their anisotropic hierarchical morphology and assembly over several length scales. The basic anatomic building blocks of the wood structure are the wood cells, in which the chemical components are arranged with high complexity in the cell wall.

The cell types present in a tree differ between softwoods (gymnosperms) and hardwoods (angiosperms). Softwoods are older from an evolutionary point of view and their cells are therefore less differentiated than those of hardwoods. Softwoods are mainly built-up by one cell type, the tracheid. Tracheids form a network of pores that is elongated in the axial direction of the tree. The annual change of seasons thereby leads to the alternating formation of denser areas with a lower porosity (late wood) and less dense areas with a higher porosity (early wood), resulting in characteristic growth rings.32-34 In addition to tracheids, softwoods contain rays. These cell strands

run through the wood in radial direction. They are usually one cell wide, but can also be composed of more than one cell layer when they contain resin canals.35

In this work, however, only hardwoods were used. In hardwoods the cell types are more diverse than in softwoods. It mainly consists of fibers, vessels, and rays (Figure 4b). Rays are built-up from a bundle of individual cells and are oriented perpendicular to the axial direction of the tree in radial direction. Fibers and vessels, on the contrary, form anisotropic pores that are elongated in the axial direction of the tree (longitudinal direction, Figure 4c). Fibers are shorter and smaller in diameter compared to vessels. Unlike individual fibers, vessels are formed by multiple cells that are connected end-to-end and form continuous tubular structures by partial or complete disintegration of their connecting transverse walls. Vessels can reach widths of tens to hundreds of micrometers and lengths of several meters.35 Moreover, neighboring cells and pores are connected by pits, which are perforations of the cell wall. They ensure mass transport between the cells, so that they form interconnected networks throughout the whole tree.33-34, 36-37 These networks of long and wide pores enable high permeability in hardwoods.38

The material wood | 9

Figure 4: (a) Photograph of a beech wood cylinder. (b) Cube reconstructed from X-ray microtomography data of a beech wood sample. The anatomical features of this hardwood are well visible with the three main components: vessels, fibers, and rays. The green axes indicate the three directions longitudinal (L, axial direction), radial (R), and tangential (T). The scale bar depicts 50 μm. (c) Schematic illustration of the microporosity of hardwoods with an arrangement of fibers as smaller pores and vessels as bigger pores. (d) Schematic illustration of a hardwood fiber with its composition of a cell wall with concentric layers around a central lumen. (e) Schematic illustration of an exemplary cutout from the secondary cell wall. Cellulose fibril aggregates (blue rods) are embedded in a matrix of lignin (yellow). Hemicelluloses (red and violet) act as an intermediate layer between cellulose and lignin. (illustration: Joshua Binswanger, Zurich University of the Arts)

All cell types share similar features when it comes to their composition. The lumen is the void in the cell’s center, which is contained by the cell wall (Figure 4d). The cell wall is built of multiple concentric layers. Adjacent to the lumen is the secondary cell wall, which is formed after the cell has stopped growing. The secondary cell wall’s main function is to provide mechanical stability to the wood structure.39 This is achieved by the above mentioned fiber-composite structure, which is illustrated in Figure 4e. The secondary cell wall has a layer-like structure that comprises three individual layers, the S1, S2, and S3 layer. Every layer is characterized by a specific angle under which the cellulose fibrils are orientated towards the fiber axis, the microfibril angle. The S2 layer is the thickest of these layers with diameters between around 1 µm in earlywood and around 5 µm in latewood. In normal wood cells its microfibril angle ranges from 0° to 20°. The S2 layer is sandwiched between the S1 layer towards the outside of the cell and the S3 layer towards the lumen.

Both these layers are much thinner than the S2 layer and have a high microfibril angle with values between 70° and 90°.40-41

Adjacent to the secondary cell wall and the outermost layer of the cell wall is the primary cell wall, which is formed during the cell growth. In comparison to the secondary cell wall, it is a thinner structure in which cellulose fibers are randomly oriented and embedded in a network of various hemicelluloses and pectin. A variety of models for the primary cell wall structure have been proposed over the last decades. The exact composition, however, is still disputed.39

Individual neighboring cells are connected to each other by the middle lamella. The middle lamella is rich in lignin and contains no cellulose. It usually has a thickness of several hundred nanometers at the flat contact areas of neighboring cells and can exceed one micrometer in the cell corners.42-43 Besides these anatomical features, the dimensions and the distribution of the cells as well as the detailed chemical composition of the wood, depend on the wood species. Furthermore, the structure is highly heterogeneous and differs between individual trees of the same species and even between early- and latewood regions of the same tree. This has implications on wood materials science, as the modification strategy and the characteristics of the resulting wood-based material will strongly depend on the structural features and the chemical composition of the wood used. Therefore, the wood species used for a certain modification has to be well considered in advance, as it will have a strong impact on the outcome of the process.

1.3.2. The hardwoods beech and poplar

The hardwoods beech (Fagus sylvatica) and poplar (Populus spp.) were used in this work. As mentioned before, hardwoods exhibit long and wide vessels, which form an interconnected network in the tree that ensures water transport from the roots to the crown.37 This vessel network guarantees a high throughput for liquids. Hence, it is of particular interest when it comes to the performance of wood-based membranes.38

Hardwoods are divided in ring-porous trees, where the vessels are distributed along the year rings, with bigger vessels in the earlywood region and smaller vessels in the latewood region, and diffuse- porous trees, where the vessels are evenly distributed over the growth ring. Additionally, there are semi-ring porous species, which are intermediates between ring-porous and diffuse-porous systems.

Vessels can occur singular or group wise. Beech and poplar are both diffuse-porous species with group wise arranged vessels (Figure 5).35

Both species have similar vessel diameters of about 30 to 100 µm.44 Individual vessels reach several centimeters in length and up to almost one meter in beech wood.45-46 The species differ, however, in the amount of vessels. In beech wood, the vessels built up to 38 % of the structure, whereas in

The material wood | 11

poplar, this value is 44 %. The overall porosity as a fraction of the total volume is also higher for poplar (73 %) than for beech (55 %).35

When it comes to the development of a wood-based membrane reactor, the interpenetrating network of wide and long vessels that is present in hard woods like beech and poplar has two implications.

Firstly, it results in a high permeability and hence enables easy penetration of the wood with modification solutions.47 This is an ideal prerequisite for thorough impregnation and sufficient modification. Therefore, these hardwoods are well suited for the impartation of novel functionalities by modifying agents. Secondly, the porosity will determine the flux, when the wood is applied as a membrane. Natural beech wood samples with a typical membrane thickness of one millimeter, for example, exhibit very high flux values.48 This is due to the length of the vessels, which exceeds the length of the sample. Hence, the open vessel network offers unhindered flow through the samples.

This effect will strongly influence the membrane performance, as the membrane flux is decisive for various kind of applications.49-50 Hence, its adjustment is necessary to optimize the membrane functionality.

Summarizing, beech and poplar provide good prerequisites for chemical modifications to create functional membrane materials due to their high permeability. However, the wide and long vessels, which cause this high permeability, also require a tuning of the porosity to regulate the flux through the structures when they are applied as membranes.

Figure 5: Images of the microstructural features of beech (left) and poplar (right) xylem tissue in two different magnifications (top: 40x, bottom: 200x). The images were acquired with an optical microscope from thin cuts, which were dyed for better contrast. (Xylothek, Institute for Building Materials (IfB), ETH Zürich, Switzerland)

1.3.3. Wood-based functional materials

The complex, hierarchical, and highly anisotropic composition of wood results in a strong anisotropy of its properties, such as mechanical performance, heat-, or water transport. In addition, wood is cheap, abundant, regrowing, CO2-storing, and biodegradable. Consequently, there has been an increase in the development of wood-based functional materials.15, 51

Wood-based functional materials combine the features and properties that result from wood’s structure with functions or characteristics that are imparted by chemical modification of the structure. However, for certain applications, it is possible to make direct use of wood’s intrinsic properties, without the use of chemical modifications. Various wood species can be used as a filter material for colloidal substances, due to their natural microporosity.18, 48, 52-53 Moreover, natural spruce wood possesses an underwater superoleophobicity and can hence separate oil droplets from an oil-water mixture.54

For further functions and applications, chemical modification of the wood is required. In general, chemical modification of wood has a long tradition. Methods like acetylation or impregnation with various copper-containing compounds were developed and are still widely applied to improve wood’s characteristics for traditional applications, mainly its use as a building material. In this regard, it is of importance to protect wood from environmental influences and increase its durability as well as dimensional stability. Hence, multiple methods have been investigated for the chemical preservation of wood against microbial decay and weathering as well as to decrease its dimensional changes upon varying moisture content.25, 55

In contrast to these traditional approaches, more recent research is focused on the creation of novel wood-based composites and hybrids that exhibit novel functions, which are not present in unmodified wood. They can roughly be divided into approaches in which wood was modified with polymers and other organic compounds, and such in which metals or minerals are brought into the wood.14

To synthesize wood-polymer hybrids, the chemical composition of the wood cell wall is exploited.

In most cases, the hydroxyl groups of the cell wall polymers are used for binding other reactants.

One approach is to directly modify the cell wall by in situ polymerization.56 Other approaches rely on a two-step processes, in which the cell wall is first modified with a polymerization initiator or polymerizable functional groups, followed by grafting-from polymerization of various monomers.57 For example, free radical polymerization can be applied to impart poly(styrene) or the pH- responsive polymers poly(2-(dimethylamino)ethyl methacrylate) and poly(methacrylic acid).

Modification with poly(styrene) yields a hydrophobic wood-polymer hybrid, whereas modification with pH-responsive polymers leads to pH-responsive hybrids with tunable sorption behavior.58-60

The material wood | 13

Furthermore, it is possible to polymerize N-isopropylacrylamide (NIPAM) inside the wood structure by radical polymerization.61 This yields a thermoresponsive hybrid of wood and poly(NIPAM). Moreover, more complex co-polymers can be synthesized by this technique to create hybrids with tunable wettability.62-63 Polymerization inside the wood structure can also increase its strength or make it more durable, by protecting it from fungal decay.64-65 Even electric conductivity was imparted by the polymerization of aniline in pine wood veneers.66

Furthermore, not only wood modification with polymers, but also with small molecules allows the introduction of novel functionalities. Functionalization of wood with citric acid or succinic anhydride introduces covalently bound carboxyl groups to the wood cell walls. The resulting wood- based material is able to absorb copper ions from aqueous solution for water purification.67

The modification of wood with metals and other inorganic compounds is another field that was investigated intensely. It can make wood more resistant against environmental influences. It has been known for many years that impregnation of wood with metal salts preserves it form microbial decay.25 Moreover, increasing woods fire-resistance is a heavily investigated topic. Wood’s high flammability is a big challenge for its application as a building material.29 Therefore, several methods of modifying wood with inorganics were developed to increase its fire resistance.

Impregnation with various inorganic salts improves the fire-retardant behavior of wood.25 More recent approaches investigated bioinspired mineralization and modification with supercritical carbon dioxide to increase wood’s fire resistance by the introduction of the mineral calcium carbonate.68-70 Another study investigated the modification of wood with struvite for increased fire retardancy. This mineral decomposes at lower temperatures than wood, absorbing heat and forming a char layer that protects the wood.71

Besides that, wood modification with zinc oxide nanoparticles leads to increased antibacterial and UV-light resistance.72 Furthermore, the formation of silica aerogel inside the wood structure was reported.73 The resulting hybrid material exhibits reduced moisture uptake compared to native wood. This behavior contributes to improved dimensional stability as well as improved thermal insulation of the material.

Apart from improving wood’s resistance to certain environmental influences, novel functionalities can be imparted by functionalization with inorganics. Magnetization of wood is an interesting approach that uses the anisotropic porosity of wood and combines it with a new function.74-81 The hybrid material is yielded by the precipitation of magnetic metal oxide particles inside the wood structure. The anisotropic deposition of the particles along the pore-direction results in an anisotropic magnetization of the hybrid material.

An interesting property of wood is the directed flow of liquids through its structure. It directly results from wood’s anisotropic porosity and is of particular interest for an application of wood as

a membrane material. Therefore, various wood-based membranes have been presented recently. On the one hand, there are membranes made of unmodified wood, which can be used as filters.18, 48, 52- 53 On the other hand, chemical wood modification was used to create hybrid functional membranes.

Modification of wood with noble metal nanoparticles yields membrane materials, which can be used for water treatment based on their ability to catalytically degrade organic dyes.20, 82-83 A similar approach is based on the incorporation of metal organic frameworks (MOFs) into the wood structure.21 Wood-MOF hybrids are able to remove organic dyes by absorption in a flow-through set-up. Moreover, directional water transport is used for solar steam generation and water purification. This is achieved by the modification of wood with narrow band-gap nanoparticles, which can absorb a major part of the solar spectrum.19

All investigations introduced in the former paragraph have in common that they strongly focus on the membrane function. However, the process parameters of wood-based membranes, like the membrane flux and particularly its regulation and influence on the process, have barely been investigated. Some studies on membrane function do not provide information about the membrane fluxes at all.18, 20, 53, 82 Others present the fluxes of the synthesized membranes in their particular set- up, without stating how the flux influences the membrane process.48, 52, 83 Only Guo et al. showed in their work on organic dye removal with wood-MOF hybrids that the removal efficiency is depending on the flux, with higher flux leading to a lower efficiency.21 This is of particular interest, as wood-based membranes in general show high fluxes due to their high porosity. Even fir as a softwood, which does not contain wide and long vessels, exhibits a high flux when applied as thin membrane (thickness: 6 mm).83 Therefore, a regulation of the flux is desirable to optimize the process parameters. However, there is no study yet about the regulation of the flux of wood-based membranes.

Moreover, the majority of wood modifications presented above do not comply with the principles of green chemistry. They rely on oil-based precursors, solvent-based chemistry, use energy- intensive production methods, or result in hybrid and composite materials that are hard to recover and recycle. Therefore, these approaches diminish the advantages that wood provides over traditional materials. As a green, renewable, and biodegradable material, it is a valuable resource in material science for the development of more sustainable materials. However, this is only the case if green modification approaches are applied. Hence, methods are desired that rely on aqueous processes without the use of fuel-based precursors or harmful chemicals. Additionally, the yielded materials have to be completely recyclable.29, 84 The use of biomolecules, such as proteins, is a promising approach to realize such green modifications that yield eco-friendly products.

Proteins | 15

1.4. Proteins

Proteins are a class of biomacromolecules that can be found in all organisms on this world, fulfilling a variety of different functions. They serve as structural and motor components, for transport and signaling, or as enzymes, which catalyze all kinds of chemical reactions and are vital for metabolic processes as well as DNA transcription and replication. Proteins come with a variety of properties that make them interesting for industrial applications. They are abundant in nature and can either be extracted from plants and animals or biotechnologically produced by microorganisms in large amounts. Furthermore, they are biodegradable and can often be processed in an aqueous environment. This makes them ideal for green processes.17, 85

Proteins have been investigated intensely in materials science.86 Various applications for proteins were proposed due to their huge variety in properties, structure, and functions. They were, for example, used for biomedical applications,87-91 for optics and electronics,92-95 as structural composites,96-97 or for damage sensing and reporting.98-99 A lot of these applications rely on the combination of proteins with structured materials or surfaces. Accordingly, proteins offer various functions that could be imparted to the wood structure by eco-friendly approaches. However, there has not yet been reported any research that combines proteins with wood for the creation of functional materials.

The basis for the huge versatility in the realm of proteins lies in their complex hierarchical structure.

Hence, it is necessary to take a closer look at their chemical and structural composition, to understand how they can be used for the creation of wood-based functional membranes.

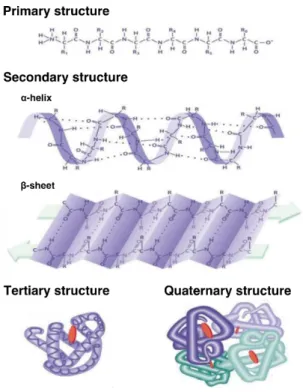

1.4.1. Protein structure

Proteins are a class of natural materials, which exhibit a hierarchical structure as well. Their morphology is divided into primary, secondary, tertiary, and quaternary structure (Figure 6). In general, they are built up of a chain of amino acids, which are linked by a peptide bond. Proteins are therefore also referred to as polypeptides. All natural proteins are composed of different combinations out of the pool of 22 natural amino acids. The characteristic amino acid sequence of a protein is called its primary structure. The backbone of the chain forms hydrogen bonds, resulting in a regular folding of the chain to stable substructures.100 There are three substructures that occur in proteins. The major structural elements are α-helices and ß-sheets. As a third element, ß-turns occur in the protein structure connecting two ß-sheets with each other. The specific combination of these sub-structures is called the secondary structure. Further folding of the chain leads to the tertiary structure of the protein. The folding is stabilized by non-covalent interactions, disulfide bonds, or coordinating metal ions. The tertiary structure defines the spatial position of all atoms in a protein. Lastly, in some proteins, more than one polypeptide chain is aggregated in a specific

three-dimensional structure to a single functional unit. This structure is called the quaternary structure of the protein.101

Figure 6: Schematic illustration of the hierarchical levels of the protein structure.102

Every protein is characterized by a unique combination of primary, secondary, tertiary, and sometimes quaternary structure. The exact structural composition of the protein is decisive for its function. It is itself defined by the chemical composition and sequential combination of the amino acids in the polypeptide backbone. A problem, which results directly from this complex composition, is a relatively low stability of the structure, as the folding is mostly stabilized by weak non-covalent bonds. Hence, proteins tend to lose their three-dimensional structure in cases of unfavorable pH, at high or low temperatures, high ionic strengths, or in organic solvents. This process is called denaturation. It is often irreversible and usually results in a loss of function. A class of proteins that are particularly relying on their structure are enzymes.103-105

1.4.2. Enzymes

Enzymes are biological catalysts that accelerate chemical reactions in all living organisms under physiological conditions. Most enzymes are proteins, but they can also be composed of RNA. In this work, only protein enzymes are relevant and hence, only these will be discussed.

Proteins | 17

1.4.2.1. Enzymatic biocatalysis

In general, enzymes (E) catalyze the reaction of a substrate (S) to a product (P) under the intermediate formation of an enzyme substrate complex (ES) and an enzyme product complex (EP).

E + S → ES → EP → E + P

The catalytic function of an enzyme directly results from its structure. The enzyme provides physical pockets in its tertiary structure, which are called active sites and can bind substrates with high affinity and specificity. According to the induced-fit model, this substrate binding induces structural changes in the enzyme, which then allow the formation of the product. The active site thereby creates a physical and chemical microenvironment that facilitates product formation.106-107 Enzymatic reactions follow special kinetics that characterize the reaction and the enzymatic activity. They were first described by Leonor Michaelis and Maude Menten in 1913.108 Michaelis and Menten based their theory on the assumptions that [EP] is low and can therefore be neglected and that the release of product from the enzyme is fast and the backward reaction of E + P forming ES can be neglected as well. Under these assumptions, the following reaction scheme results for determining the kinetic parameters:

The Michaelis-Menten kinetics work for [S] ≫ [E] and assume that a steady state is reached quickly after the reaction is started. In the pre steady state condition, the enzyme-substrate complex is formed with the rate constant k1 until a certain concentration of ES is established. In the following steady state, [ES] stays constant for the remaining reaction. When [ES] is constant, its formation equals its breakdown:

k1[E][S] = k−1[ES] + k2[ES] (1) k1[E][S] = (k−1+ k2)[ES] (2)

The Michaelis constant KM is then defined as the ratio of the rates of formation and breakdown of ES:

KM=(k−1+ k2)

k1 (3)

Furthermore, the total amount of enzyme [E]t is

[E]t= [E] + [ES] (4)

Leading to

[E] = [E]t− [ES] (5)

In combination with (2) this leads to

k1([E]t− [ES])[S] = (k−1+ k2)[ES]

k1[E]t[S] − k1[ES][S] = [k−1+ k2][ES]

k1[E]t[S] = k−1[ES] + k2[ES] + k1[ES][S]

k1[E]t[S] = (k−1+ k2+ k1[S])[ES]

[ES] = k1[E]t[S]

k−1+ k2+ k1[S]

[ES] = [E]t[S]

k−1+ k2 k1 + [S]

[ES] = [E]t[S]

KM+ [S] (6)

The initial velocity of the reaction v0 is

v0= k2[ES] (7)

and hence,

v0 =k2[E]t[S]

KM+ [S] (8)

The maximum velocity vmax is reached when all E is present as ES

vmax = k2[E]t (9)

from this, the Michaelis-Menten equation is derived as v0= vmax[S]

KM+ [S] (10)

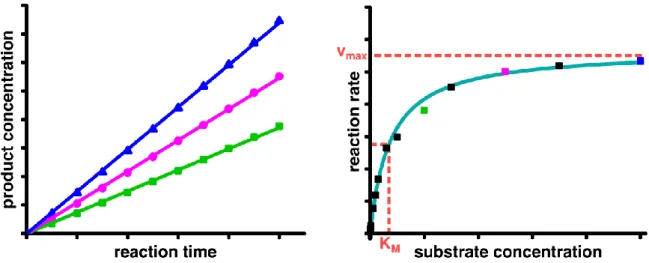

Equation (10) shows how the kinetic parameters KM and vmax can be determined experimentally.

First, initial reaction rates are determined for various substrate concentrations. They are derived as linear fits of the product concentration over reaction time (Figure 7 left). After plotting these

Proteins | 19

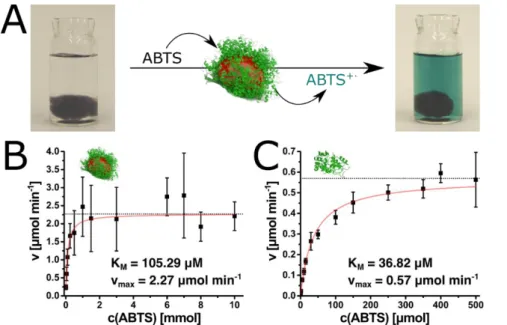

reaction rates against the substrate concentrations, the parameters can be obtained by a hyperbolic fit (Figure 7 right). The Michaelis-constant is the substrate concentration at which 0.5 vmax is reached. It is an inherent property of the enzymatic system and independent from the enzyme concentration. It is therefore used as a measure to compare enzymatic activity under various conditions.

Figure 7: The kinetic parameters of an enzymatic reaction are obtained by plotting the initial reaction rates, derived as the linear fit of the product concentration over time (left), against the substrate concentration (right). Subsequently, a hyperbolic fit gives the values KM and vmax.

Another parameter that provides information about the enzymatic activity it the turnover number kcat. It is defined as

kcat =vmax

[E]t (11)

and depicts the maximum catalytic activity at very high substrate concentrations. It describes how much product is produced by one enzyme in a given time.

For all of these considerations, it has to be regarded that the enzymatic activity is strongly depending on environmental influences such as temperature or pH-value of the reaction solution. Every enzyme has its specific optimum at a certain temperature and a certain pH-value. Most enzymes, however, work under physiological conditions, which means neutral pH and relatively low pressure and temperatures. These moderate reaction conditions, in combination with their high catalytic activity and specificity, make them highly interesting for industrial applications. They can provide greener alternatives for established processes, for example in synthetic chemistry or waste treatment.23 Furthermore, enzymes are already used when it comes to the production of fine chemicals, pharmaceutical compounds, or ingredients for cosmetics, as well as for treatment of food and textile products and in the pulp and paper industries.109

However, there are two main problems that impede a more extensive use of enzymes. Firstly, enzymes exhibit a low stability in unfavorable environmental influences, as their catalytic activity is highly depending on their three-dimensional structure. This structure mainly depends on non- covalent bonds that can be cleaved easily, resulting in denaturation. Aside from the enzyme’s optimum conditions, the catalytic activity decreases, until it eventually vanishes due to structural failure of the enzyme structure. Furthermore, most enzymes are not active in organic solvents.

However, some industrial processes may only work in organic solvents or require certain environmental conditions, which may impede enzyme activity. Therefore, enzymes in their natural state are often not applicable for industrial processes.109-111

Secondly, enzymes are homogeneous catalysts by nature. Hence, they are hard to remove from the reaction solution after the reaction took place and remain as impurities in the reaction product. This is particularly problematic for applications in which a high purity of the product is required, for example in drug synthesis. Moreover, a reuse is not efficiently possible when the separation of the biocatalyst from the reaction solution is not straightforward. As a result, enzymes are mainly applied for single-use applications. The feasibility to reuse the enzymes, though, would increase their cost-effectiveness and reduce the environmental impact of enzyme catalysis.109, 111

To overcome these problems, enzymes can be immobilized to solid insoluble scaffolds. Enzyme immobilization can increase their stability and facilitate their reuse.112 Moreover, the combination of enzymes with a scaffold can impart additional functions to the biocatalysts. Therefore, enzyme immobilization has become an intensely investigated research field.110

1.4.2.2. Enzyme immobilization

Enzyme immobilization depicts the binding of enzymes to an insoluble scaffold. By the attachment to these scaffolds, the enzyme structure can be stabilized, resulting in a higher tolerance towards unfavorable environments. Furthermore, enzyme immobilization transfers the biocatalysts from a homogeneous system to a heterogeneous one. A big advantage of heterogeneous biocatalysis is the facilitated separation of the catalyst from the reaction solution and the possibility of multifold reusability.110, 113-114 Moreover, enzyme immobilization can allow the implementation of biocatalysis in continuous-flow processes.115

1.4.2.2.1. Immobilization scaffolds and methods

The selection of the scaffold is crucial for the immobilization. A large variety of scaffolds has been proposed. They range from inorganic materials such as metal colloids over polymeric materials to natural materials such as various polysaccharides.116 The sizes of possible scaffolds comprise several orders of magnitudes and reaches from nanosized or nanoporous materials over micrometer

Proteins | 21

sized structures to macroscopic entities.117-118 In general, a scaffold should offer a high accessible surface area as well as the possibility to robustly bind the enzyme.119-120

There are multiple ways for binding the enzyme to the scaffold (Figure 8).116 One possibility is to entrap the enzyme in the porous structure of a scaffold. The enzyme is not directly bound to the scaffold, but rather encaged by its structure in this approach.121 Hence, the structure of the enzyme is mostly not affected, which is beneficial for retaining the catalytic activity after the immobilization. However, it can be difficult to achieve an appropriate pore size that blocks the enzyme, but at the same time allows passage of substrate and product to and from the enzyme. If the pores are too big, the enzyme can leach from the structure, whereas the substrate cannot diffuse to the enzyme when the pores are too small.120-121

Figure 8: Schematic illustration of the three main strategies for enzyme immobilization.

Entrapment of the enzyme in a porous scaffold, covalent binding, which can allow site-specific binding keeping the enzymes’ active sites accessible, and adsorption by unspecific binding with partly blocked active sites.

Another method is the covalent binding of the enzymes to the scaffold. Thereby, the enzymes are bound by chemical reactions to the scaffold, either directly or with the help of a linker. The advantages of this approach are the strong binding, which prevents enzyme leaching, as well as the high enzyme loading that can be realized. Furthermore, enzymes offer a variety of functional groups, which can be used for the binding reaction. This can be utilized for site-specific binding to prevent blocking of the active centers of the enzymes. Multi-point covalent attachment can

additionally increase the enzyme stabilization due to rigidification of the structure.122-123 However, strong binding can also result in structural distortion of the enzymes leading to decreased catalytic activity.124 Furthermore, chemical binding requires additional reaction steps for the binding itself and for possible pre-modification of the enzyme or the scaffold. This can make the methods more complicated and increases their environmental impact.120

The third method for enzyme immobilization is physical adsorption. It depicts enzyme binding to the scaffold by physical attraction forces, such as van-der-Waals force or charge interactions.120 The bonds are weaker than covalent bonds, resulting in less distortion of the enzymatic structure.

Moreover, adsorption processes are often easy to realize without additional reaction steps or pre- modifications as enzymes, and proteins in general, readily adsorb to various surfaces.125 However, the weak binding can result in enzyme leakage from the scaffold. Additionally, site-specific binding is hard to realize by this method, as physical interactions are isotropic forces and the enzyme orientation can hardly be influenced. As a result, blocking of the active center might occur, resulting in reduced catalytic activity after the binding.126

A particularly well-suited material for enzyme adsorption are metals. Proteins readily adsorb to metal surfaces and metal colloids.127-129 Especially in the case of noble metals, such as gold and silver, a strong binding is established. The robustness of the binding is based on strong coordinative bonds between electron-rich moieties in the proteins, such as thiol- or amino-groups, and the metal surface. Proteins can thus easily displace smaller molecules or even polymers from colloidal metal surfaces in a ligand exchange process. It has been shown that enzymes can be bound to metal colloids by this technique under retention of their biocatalytic activity. No enzyme leakage occurred due to the strong bonds between metal and enzymes.130-132

In general, it is necessary to find an optimal interplay between the enzymes, the scaffold, and the immobilization method to realize a hybrid system with the desired properties. The enzymes are the functional component of the system, which define the reactions that can be catalyzed and their kinetics. The scaffold is decisive for the reusability of the system and the modus of implementation of the final catalyst.133 Furthermore, it can add additional features to the system, such as magnetizability or defined optical properties.134 The immobilization method should then be tailored to achieve robust binding of the enzymes without leaching as well as retaining of a high catalytic activity of the final catalyst. Moreover, factors like feasibility, variability, environmental impact, or cost-effectiveness of the method play a decisive role in the process.

1.4.2.2.2. Continuous-flow biocatalysis

A concept that has been realized with the help of enzyme immobilization is continuous-flow biocatalysis. For this approach, the enzymes are immobilized to scaffolds, which can be imbedded to or directly used themselves as a flow-reactor. Hence, a continuous production of the desired