Surface properties of monolithic zirconia after dental adjustment treatments and in vitro wear simulation

Verena Preis

a,* , Michael Schmalzbauer

b, Dominique Bougeard

b, Sibylle Schneider-Feyrer

a, Martin Rosentritt

aaDepartmentofProstheticDentistry,RegensburgUniversityMedicalCenter,Regensburg,Germany

bInstituteforExperimentalandAppliedPhysics,UniversityofRegensburg,Germany

article info

Articlehistory:

Received6May2014 Receivedinrevisedform 8August2014

Accepted15August2014

Keywords:

Monolithiczirconia Adjustment Polishing Wear Roughness

Phasetransformation

abstract

Objectives: Toinvestigatethesurfaceproperties(roughness,composition,phasetransfor- mation)ofmonolithiczirconiaspecimensafterdentaladjustmentprocedures(grinding, polishing)andwearsimulation.

Methods:Zirconiaspecimens(Cerconbase,Cerconht,DeguDent,G;n=10/material)were successivelysintered,ground,andpolishedwithanintraoralpolishingkitinathree-step procedure.Sinteredzirconiaspecimenswithhighsurfaceroughnessservedasareference.

Foreachtreatmentstep,wearsimulationswithsteatiteplates(d=10mm)asantagonists wereconductedaswellassurfaceroughnesstests(Ra),EDXanalysis,andX-raydiffraction (XRD) measurements. SEM pictures were taken, and data were statistically analyzed (one-wayANOVA,posthocBonferroni,a=0.05).

Results: Grindingsignificantly(p=0.000)increasedtheroughnessofsinteredzirconiaupto values of1.360.11mm (Ra).Polishing significantly (p=0.000) reduced Ra. The lowest roughnessvalueafterthefinalpolishingstepwas0.200.03mm.Weartestingresulted inafurtherslightdecreaseofRa.Afterthegrindingprocedure,SEMpicturesshoweddeep grooves thatwere progressivelysmoothedby polishing. TheEDX spectrashowedthat magnesiumwastransferredfromsteatiteantagoniststozirconiabywear.In theXRD- patterns,monoclinic(m)peakswereobservedaftergrindingandpolishing.Themaximum intensityratiobetweenthem(111)peakandthetetragonalt(111)peakdecreasedafter thecompletionofallpolishingsteps.Weardidnotinducephasetransformation.

Conclusions: Adequatepolishingreducedtheroughnessofgroundzirconia.Wearhadlittle influenceonroughnessandnoinfluenceonphasetransformation.

Clinicalsignificance:Carefulpolishingisrecommendedtokeepsurfaceroughnessandphase transformationlow.

#2014ElsevierLtd.Allrightsreserved.

*Correspondingauthor at:Department ofProstheticDentistry,UniversityMedicalCenterRegensburg,93042Regensburg,Germany.

Tel.:+499419446073;fax:+499419446171.

E-mailaddress:verena.preis@ukr.de(V.Preis).

Availableonlineatwww.sciencedirect.com

ScienceDirect

journalhomepage:www.intl.elsevierhealth.com/journals/jden

http://dx.doi.org/10.1016/j.jdent.2014.08.011 0300-5712/#2014ElsevierLtd.Allrightsreserved.

1. Introduction

Full-contourzirconiacrownsandfixedpartialdentureshave become an alternative treatment option to commonly veneered zirconia-based restorations, particularly in less visibledentalareas.Chairsideadjustmentofzirconiarestora- tionsisusuallyrequiredtoachieveoptimalocclusalcontact situations.Suchsurfacemanipulationsincludegrinding,and thisprocedureresultsinthecircumscribedlossoftheglaze layer and surface smoothness. Subsequently, use of an intraoralpolishingkithasbecomeawell-establishedalterna- tivemethod tore-glazing but this procedure isnot conse- quentlyappliedbyalldentists.Overthesubsequentclinical service time, zirconia surfaces becomedirectly exposed to wear.Evenwithouttheapplicationofanyprecedingadjust- mentprocedure,thinglazelayersareknowntobecomeworn within the first six months after the insertion of the restoration,1thusuncoveringthezirconiasurface.

Anyadjustmentprocedureofzirconiasurfacesmayinduce superficialmodifications,damage,andphasetransformation fromthetetragonal(t)tothemonoclinic(m)phase.2–4Such changescannegativelyinfluencethemechanicalpropertiesofa zirconia restoration, for example, with regard to flexural strength,hardness,andelasticmodulus.4–6Furthermore,such changescanhavedetrimentalconsequencesforthelong-term behaviourofarestorationduringclinicalservice.Ahight!m transformationratemaydecreasethemechanicalstabilityover timebecausezirconialosesitstougheningeffectandresistance against crack propagation.7 Because surface roughness and damage are also known to influence the wear process,8,9 differentsurface manipulations carriedout bydentistsmay alterthewearperformanceofzirconia.Otherinvestigations havealreadyshownthatthewearofmaterialandantagonistof smoothlypolishedzirconiaspecimensisevenlessthanthatof veneering and glass ceramics.9,10 Furthermore, the wear processitselfcaninfluencethesurfaceroughnessofzirconia, causedebris,andleadtophasetransformation.Manystudies haveinvestigatedzirconiasurfacesmanipulatedbysandblast- ingorgrindingfortheadaptionofinnerzirconiasurfacesorto increasebondingtothetooth.3,4,11,12However,littleisknown abouttheconsequencesofocclusalsurfacemodificationsof zirconiabychairsideadjustmentproceduresfollowedbywear simulation.

Thehypothesisofthisstudywasthatsurfaceroughness and phasetransformation areinfluenced by dentaladjust- mentprocedures(grinding,polishing)andwear.

2. Materials and methods

2.1. SpecimenpreparationSpecimens(10discspermaterial,diameter20mm,thickness 1.5mm) were preparedfrom two different yttria-stabilized zirconiaceramics(Cerconht,Cerconbase,bothbyDeguDent, Hanau,G).Thespecimenswerecutatthepre-sinteredstage with a water-cooled diamond saw (Accutom 2, Struers, Willich,G)andthen sintered(Cerconheatplus,DeguDent).

Cercon base, a common zirconia material with low

translucency,wassinteredat13508C(hardness:1454HV10, fracture toughness: 6.4MPam1/2). Cercon ht with higher translucency (ht) was sintered at 15008C (hardness: 1485 HV10, fracturetoughness: 8.1MPam1/2).Twofurtherspeci- mens (Cercon base) thatwereadditionally roughenedwith silicon carbide grinding paper (Buehler, Lake Bluff, USA) before sintering served as a sintered reference with high surface roughness becausea potentialinfluence ofsurface roughnessonphasetransformationwasassumed.

To simulate clinical adjustment procedures carried out bydentistsinclinicalpractice,specimensweresubjectedto differentsurfacetreatmentsaftersintering.Zirconiaceramics were successively ground and polished in three steps.

Grinding was done with a diamond bur (837LF FG 014, 27–76mm,Meisinger,Neuss,G)understandardizedconditions (permanentwatercooling,1N,160,000rpm,10s).Toachievea high-glosssurfaceoftheceramics,polishingconsistedofthe progressiveuseofa3-stepintraoralpolishingset(CeraGlaze, P335,P3035,P30035,NTI,Kahla,G)inadefiniteprocedure(2N, 30s,step1:15,000rpm,step2:10,0000rpm,step3:5000rpm) accordingtotheinstructionsofthemanufacturer.Aftereach stepofthisprocess(sintering,grinding,andpolishingstep1, step2,step3),twospecimensofeachmaterialwerekeptatthe obtained surface stateforfurtherinvestigation. Oneofthe twospecimenswassubjectedtowearsimulation(ZM-3;SD MechatronikFeldkirchen-Westerham,G)withsteatiteplates (d=10mm,CeramTec,Plochingen,G)thatservedasantago- nists. Loaded with 25N, circularmovements with atravel pathof8mmwereconductedfor120,000cyclesatavelocity of20mm/sandunderwater-cooling.

2.2. Surfaceroughness

After each step of the surface treatment and after wear simulation,surfaceroughnessRa(arithmeticaveragerough- ness) was determined perpendicularly to the grinding or polishingdirectionbymeansofaprofilometriccontactsurface measurement device (Perthometer SP6, Feinpru¨f-Perthen, Mahr, Go¨ttingen, G; 5 measurements per specimen;

LT=1.7mm/0.25mm, velocity0.1mm/s,2mmdiamond in- denter).

2.3. Scanningelectronmicroscopy(SEM)andenergy dispersiveX-rayspectroscopy(EDX)

SEM (working distance: 20.4mm; voltage: 5–10keV; low vacuum;QuantaFEG400,FEICompany,Hillsboro,USA)was usedforqualitativesurfaceevaluation.Surfaceswereexam- ined at magnifications between 500 and 30,000. Elemental compositionwasdeterminedbyEDXanalysis(EDAXGenesis 2000, Ametek, Meerbusch,G) atamagnification of1000. To determinethepotentialmaterialtransferduringwearsimula- tion,weinvestigatedbothspecimensandsteatiteantagonists.

2.4. X-raydiffraction(XRD)

XRDanalysis(D5000diffractometer,Siemens,Munich,G)by means of Cu Ka1 radiation was conducted to examinethe influenceofdifferentsurfacetreatmentsandwearsimulation on the phase composition and transformation of zirconia.

Thespecimensweremountedintosampleholders,andscans were conducted at 40kV/40mA. Diffraction profiles were acquiredinarangefrom208to388inacontinuousu/2uscan withastepsizeof0.0048andacountingtimeof4.0s/step.To getanoptimalsignal-to-noise-ratio,werepeatedeverysingle scan 5times inthe same measurement run and averaged allvalues.TheresultswereplottedwithQtiPlotA(ProIndep ServS.r.l.,Craiova,Romania).Theidentificationofphaseswas based on the ICSD database (Inorganic Crystal Structure Database,FIZKarlsruhe,G).Theratioofthemaximumpeak intensitiesofthemonoclinicm(111)andtetragonalt(111) phaseswasusedtocomparetheextentofphasetransforma- tion after different surface treatments. The absolute peak intensities of both phases showed variations in time that wererelatedtotheX-raycathode.Theratioofbothdiffraction peaks, however,was verifiedtobeconstant intimeforall specimens.Finally,thefullwidthathalfmaximum(FWHM)of thet(111)peak wasextractedwithOrigin 8.1G(OriginLab Corporation,Northampton,USA).

Calculationsandstatisticalanalysiswerecarriedoutusing IBMSPSSStatistics21.0(IBM,Armonk,NY,USA).Meanvalues andstandarddeviations(SD)werecalculatedandanalyzedby means of one-way analysis of variance (ANOVA) and the Bonferronimultiplecomparisontestforposthocanalysis.The levelofsignificancewassettoa=0.05.Theexpectedstatistical powerfor thechosen number ofmeasurements (n=5) per groupwas97.7%(G*Power3.1.3,UniversityKiel,Germany).

3. Results

3.1. Surfaceroughness

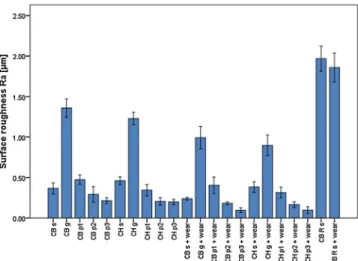

Surface roughness Ra values (Fig. 1) showed statistically significant(p=0.000)differencesbetweenthevariousgroups.

Grinding of the sintered surfaces significantly (p=0.000) increased Ra. High surface roughness was significantly (p=0.000)reducedafterthefirstpolishingstepforbothzirconia

materials.Roughnesswasfurtherreducedbythesubsequent polishingsteps.However,step1andstep2aswellasstep2and step3didnotdiffersignificantly(p>0.05)inanymaterial.Wear testing resultedin afurther slightdecrease inRa, although thisdifferencewasonlysignificant(p=0.000)fortheground specimensofthetwozirconiamaterials.Inallothersurface treatments,weartestingdidnotsignificantlyreduce(p>0.05) surfaceroughness.Thereferencegroupshowedsignificantly (p=0.000) higher Ra values than all other specimens, both beforeandafterweartesting.Whencomparingthezirconia materialsCerconbaseandCerconht,specimenswiththesame surface treatment did not show any significant (p>0.05) differencesinroughness,neitherbeforenorafterweartesting.

3.2. Scanningelectronmicroscopy

SEM images of both zirconia materials (Table 1) showed plainsintered surfaceswithafine-grainedstructurebefore weartesting.Thesurfacesshowedsomesmallimperfections and holes. Grinding made the surfaces appear rough and melted with deep grinding grooves, and grain boundaries widely disappeared. After the subsequent polishing steps, the surfaces were progressively smoothed, but some deep grindinggroovescouldnotbeentirelyremoved.

Fig.1–SurfaceroughnessRa(mean,standarddeviation)of thezirconiaspecimens(Cerconbase:CB,Cerconht:CH, Reference:R)withdifferentsurfacetreatmentsbeforeand afterweartesting:sintering(s),grinding(g),polishingstep 1(p1),step2(p2),step3(p3).

Table1–SEMimages(magnification:30,000T)ofzirconia (Reference:R)withdifferentsurfacetreatmentsbefore andafterweartesting:sintering(s),grinding(g),polish- ingstep1(p1),step2(p2),step3(p3).

Wear testingwithsteatiteplates asantagonistssuperfi- ciallypolishedtherespectivespecimens.Grainboundariesof sintered specimens partly disappeared and were smeared.

The formation of adhering clusters of worn steatite was observed,inparticular ongroundsurfaces ofboth zirconia materials.Polishedand wornzirconia specimensshoweda stepwisesmootheningofsurfaces,partlycoveredbysmeared weardebris.Somedeepgrindinggroovespersisted.

Despite higher roughness values, SEM images of the sinteredreferenceseriesshowedgrainstructuressimilarto those of other sintered specimens with lower roughness values.

3.3. EDXanalysis

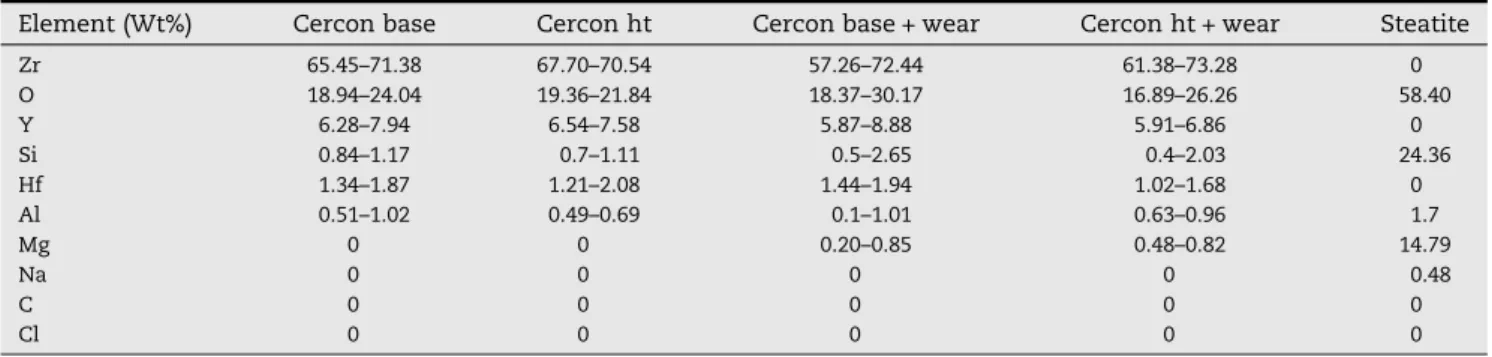

SEM observations of material transfer from the steatite antagoniststothezirconiaspecimenswereverifiedbyEDX analysis.TheEDXspectrashowedthatthesteatitesurfacewas composedofSi,Mg,O,Na,andAl.Zirconiasurfacesshowedan elementalcompositionofZr,O,Y,Si,Hf,andAlbeforewear testingthatwasverifiedforallspecimensafterthedifferent surface treatments. Because the surfaces of all specimens werefreeofMgbeforeweartestingandsteatiteshowedahigh percentage(Wt%)ofMg(Table2),weinvestigatedapotential transferofmagnesiumfromtheantagoniststothespecimens.

Worn zirconia specimens showedan Mg content of up to 0.85Wt% for bothzirconia materials.Elements found both on steatiteandzirconia specimens (O, Si,Al) showedhigh deviationsinWt%.

3.4. XRDanalysis

RepresentativeXRDpatternsofzirconiaareshowninFig.2.

Monoclinic peaks with an orientation to m (111) were detected for all zirconia specimens after the grinding and polishing procedures. Sintered specimens, including the reference specimens, did not show any monoclinicpeaks, neitherbeforenorafterweartesting.Themaximumintensity ratiosbetweenthem(111)peaksandthet(111)peaksare giveninFig.3.Becauseofm(111)/t(111)ratiosbetween 0.049 and 0.091, grinding and polishing procedures were showntoinducetetragonaltomonoclinicphasetransforma- tion.Thefinalpolishingstepdecreasedthemonoclinicphase shareinallgroupsagain.Thelowestm/tratiowasfoundafter polishingstep3forCerconhtbeforeandafterweartestingand forCerconbaseafterweartesting.Almostnodifferencewas foundafterpolishingsteps2and3forCerconbasebeforewear

testing.Independentofthesurfacetreatmentsapplied,wear testing did not have any distinct influence on the phase transformationratesofspecimens.

Comparedtothesinteredstate,allgrindingandpolishing proceduresshowedadecreaseandasymmetricalbroadening ofthet(111)peakcombinedwithanincreaseintheFWHMof thispeak(Table3).DespiteofvariationsintheFWHMwithin thedifferentgroups,bothzirconiamaterials,withorwithout wearsimulation,showedadecreasedFWHMafterthethird polishingstep.Allsurfacetreatments(grindingandpolishing) Table2–EDXelementalcompositionofsteatiteandzirconia(Cerconbase,Cerconht)beforeandafterweartesting.

Element(Wt%) Cerconbase Cerconht Cerconbase+wear Cerconht+wear Steatite

Zr 65.45–71.38 67.70–70.54 57.26–72.44 61.38–73.28 0

O 18.94–24.04 19.36–21.84 18.37–30.17 16.89–26.26 58.40

Y 6.28–7.94 6.54–7.58 5.87–8.88 5.91–6.86 0

Si 0.84–1.17 0.7–1.11 0.5–2.65 0.4–2.03 24.36

Hf 1.34–1.87 1.21–2.08 1.44–1.94 1.02–1.68 0

Al 0.51–1.02 0.49–0.69 0.1–1.01 0.63–0.96 1.7

Mg 0 0 0.20–0.85 0.48–0.82 14.79

Na 0 0 0 0 0.48

C 0 0 0 0 0

Cl 0 0 0 0 0

Fig.2–XRDpatternsofzirconiaafterdifferentsurface treatments(example:Cerconhtbeforeweartesting).

0 0 0 0 0 0

0 0.01 0.02 0.03 0.04 0.05 0.06 0.07 0.08 0.09 0.1

CB s CB g CB p1 CB p2 CB p3 CH s CH g CH p1 CH p2 CH p3 CB s + wear CB g + wear CB p1 + wear CB p2 + wear CB p3 + wear CH s + wear CH g + wear CH p1 + wear CH p2 + wear CH p3 + wear CB R s CB R s + wear

m (11-1)/ t (111) ratio

Fig.3–Maximumintensityratiosm(11S1)/t(111)ofthe zirconiaspecimens(Cerconbase:CB,Cerconht:CH, Reference:R)withdifferentsurfacetreatmentsbeforeand afterweartesting:sintering(s),grinding(g),polishingstep 1(p1),step2(p2),step3(p3).

ledtoareversalofintensitiesofthetetragonalpeakst(002) andt(020).Theintensityratiobetweenthet(002)andthet (020)peakwasabout0.7forsinteredspecimens,but1.2–1.7 aftersurfacemanipulation.

4. Discussion

Thisstudyconfirmedthepartofthehypothesisthatsurface roughnessandphasetransformationareinfluencedbydental adjustmentprocedures(grindingandpolishing).Withregard toweartesting,thehypothesiswasrejectedbecausewearhad onlyamarginalinfluenceonroughnessandnoinfluenceon phasetransformation.

Grindingresultedinroughandgroovedzirconiasurfaces.

Subsequentpolishingstepsreducedsuchsurfaceroughness.

ThefinalsurfaceroughnessRavalueafterthecompletionofall polishingstepswasabout0.2mmforbothzirconiamaterials, andthisvalueissimilarorevenlessthanthatreportedfor glazelayers.9,13Withregardtoroughness,theuseofazirconia polishingkitmaybeareasonableandtime-savingalternative method to re-glazing. Nevertheless, even longer polishing timesmaybenecessarytocompletelyremovedeepgrinding grooves. Thus, hard zirconia surfaces need to be polished accuratelywithoutomittinganyofthepolishingsteps.

High-gloss zirconia becomeseven moreimportant as a dental material when applied in full-contour restorations becausesmoothzirconiasurfacescauselesswearofantago- nisticenamelthanconventionalveneeringceramics.9,14,15In contrasttopolishedzirconia,roughzirconiamightcontinu- ouslydamagetheantagonistictoothinthelongterm.

The comparably high decrease in roughness values for groundsurfacesafterweartestingwasmainlycausedbydeep groovesfilledwithweardebrisoftheantagonist.Accordingly, SEM images showed zirconia surfaces smeared with wear debrisandadheringclustersofwornsteatite.Thisphenome- nonwasmorepronouncedingroundsurfaces butwasalso observed insintered and polished zirconia specimens.EDX analysis verified this materialtransfer from steatite that is composedofmulti-componentcrystalline phasesofmagne- sium-aluminium-silicate.16Asanantagonisticmaterial,stea- titemaynotbeanidealsubstituentforhumanenamelbecause ofitsdifferingmechanicalandtribologicalproperties,suchas higherhardness(steatite:680HV;enamel:330HV)17orinitial roughness(steatite:1.70.2mm;enamel:0.90.2mm)10butit allowsthestandardizationofantagonisticconditions.

Furthermore,manyotherfactorsareexpectedtocontribute tothecomplexityofthe wearprocess.Wearingeneralisa consequenceoftheinteraction between surfacesmovingin contact,causingthegradualremovalofmaterial.18Influencing factorsaretheabrasivenatureoffood,thepropertiesofthe

antagonist material, and the individual chewing behaviour combined with parafunctional habits and neuromuscular forces.18–20The underliningtribologicalmechanismsinclude abrasive,adhesive,fatigue,andcorrosivewear.18,21Undoubt- edly, clinicaltests are essential for estimating thecomplex wear,grinding,andpolishingperformanceofdentalmaterials.

However, such in vivo evaluations are often restricted by highcostsandcoincidewithhighvariabilityamongstpatients because individual chewing forces or ambient conditions cannotbesufficientlycontrolled.22,23Incontrast,invitrostudies maynotonlyallowtheinvestigationofsingleparametersofthe adjustmentandwearprocessbutalsoacomparativeevaluation ofdifferentmaterialsunderstandardizedconditions.However, eveninvitrowearsimulationsshowconsiderablevariability.24 Because of their superior mechanical properties, yttria- stabilizedtetragonalzirconiapolycrystals(Y-TZP)seemtobe predestinedasasubstructurematerialforfixedpartialdentures (FPDs)andfull-contourrestorationsinposteriorareas.25The increasedfracturetoughnessofY-TZPmay beexplainedby phase transformationfromthetetragonaltothemonoclinic phase uponexternalapplicationofstressaccompaniedbya 3–5% increase in volume.7 The associated development of localcompressivestressclosescracktipsandpreventsfurther propagation.Asaconsequenceofchairsidesurfacemanipula- tions,superficialphasetransformationsmayoccurandzirco- niamayprematurelylosethiscrack-stoppingeffect.

Calculationsofthem(111)/t(111)ratiosofthemaximal peakintensitiesintheXRDresultsallowedacomparisonof theextentofsuperficialphasetransformationafterdifferent surface treatments without calculating the exact volume fractions.Thisratiowasshowntobeindependentoftime- dependentabsoluteintensityvariationsthatwererelatedto thecathodeintheX-raytube.Informerstudies,thet!m phasetransformationwascharacterizedbyvariousmethods, forexamplebyXRD,2,4,12,26,27Ramanspectroscopy,28,29and scanningpowder-diffraction-basedcontrasttomography(m- CT-XRD).3 Calculated intensities and volume fractions strongly depend on the method of measurement and do not allow any direct comparisons. Thepenetration depth affectstherelativeamountofthemonoclinicsignal.3Forthe appliedXRDanalysis,signalsoriginatedfromapenetration depthof1–3mm.30Onlythecombinationofdifferentmethods may allow the comprehensive characterization of the transformed zone. Therefore, in the present study, we focusedoninvestigatingthem(111)/t(111)ratioinstead of reporting the exactvolumefractions.In previous stud- ies,2,3,31 volume fractions of the monoclinic phase after grinding,polishing,ordiamond-cuttingwerereportedtobe lowerthan 5–10%.Although no direct comparisonsto the volumefractionsofthesestudiesarepossible,thepresent m/t ratios between 0.049 and 0.091 indicate low phase Table3–FWHM(fullwidthathalfmaximum)ofthet(111)peak.

FWHMoft(111)peak(8) Cerconbase Cerconht Cerconbase+wear Cerconht+wear

Sintered 0.179 0.201 0.193 0.244

Ground 0.473 0.518 0.506 0.484

Polishedstep1 0.721 0.427 0.337 0.604

Polishedstep2 0.360 0.423 0.330 0.337

Polishedstep3 0.337 0.290 0.329 0.314

transformation rates and may be seen as an appropriate evaluationmethodofthet!mtransformation.

Nomonoclinicphaseswerefoundonthesurfaceofanyof thesinteredspecimens.Weartestingdidnotinduceanyphase transformationofthesespecimens.Sinteredreferencespeci- menswithhighRavaluesshowedthatthem(111)/t(111) ratiowasindependentofsurfaceroughness.Althoughthem/t ratio varieswithin the firstpolishing stepsand grinding,a trendtolowestvalueswasfoundafterthecompletionofall polishingsteps,bothwithorwithoutwearsimulation.This findingunderlinestheimportanceofcarefulpolishingwithout omitting anypolishingsteps. Areasonfor thevarying m/t ratiosintheprecedingstepsmaybesomeretransformation fromthemonoclinictothetetragonalphase,resultingfrom the low thermalconductivity ofzirconia and localheating during manipulation.32,33 A further reason may be the presenceofdeepgrindinggroovesthatwerenotreachedby all treatment steps. The variability of this ratio was also observedforspecimensafterwear testing.However, phase transformation isnotsupposedtobe inducedby wearbut rather by the previous surface treatments because worn sinteredspecimensdidnotshowanyphasetransformation.

Nevertheless,theappliedwearassaymaybeviewedasgentle weartesting.Otherwearassays(e.g.pin-on-blockorthree- body wear) in combination with higher force impactsand differentenvironmentalconditions(e.g.foodbolus)mayshow differentresultsandcausephasetransformation.

The broadening of the tetragonal peak after surface manipulation may be explained by a strained tetragonal structurebecauseoneoftheinfluencingfactorsoftheFWHM islatticestrain.Thisassumptionwouldbeconsistentwiththe reductionintheFWHMandthedecreaseinthem/tratioafter completionofallpolishingsteps.AnincreaseintheFWHM withsandblastingfollowedbyadecreaseduringtheveneering simulation was described by Hallmann.12 Accordingly, the phase transformation aftergrinding was described as suc- cessfullyreversedbyannealing.34Althoughlatticedistortion is seen as the most probable reason for the observed broadening of the tetragonal peak, a further explanation may be the formation of a new phase (rhombohedral or cubic).11,34However,thepresenceofanadditionalphasecould notbeinferredfromthepresentXRDpatterns.Areversalof theintensitiesofthetetragonalpeakst(002)andt(020)after surface manipulations may be explained by ferroelastic domainswitching.35

Theresults ofthis studyapplytotwozirconiamaterials providedbythesamemanufacturer.Differentzirconiamateri- als show similar composition but may differ in sintering temperature andresulting grain sizes.Particularly sintering conditionsmayinfluencemicrostructure,longevity,hydrolytic performance,andfinallywear.Asmallgrainsizemayimpair tetragonaltomonoclinictransition,andsmallamountsofAl2O3

improvecorrosionstability.Therefore,furtherinvestigations withdifferentzirconiamaterialsarerecommended.

5. Conclusions

Withinthelimitationsofthisstudyandthefactthatonlythe zirconia material of one manufacturer was used, we may

concludethatcarefulpolishingincludingallpolishingsteps reduced thesurfaceroughnessofgroundzirconia.Them/t ratiosindicated thelowestphasetransformationratesafter the final polishing step. Wear was shown to have minor influenceonroughnessandnoinfluenceonphasetransfor- mationbutresultedinmaterialtransferfromantagonists.In clinicalapplication,zirconiashouldbepolishedaccordingto theinstructionsofthemanufacturertokeepvaluesforsurface roughnessandphasetransformationaslowaspossible.

references

1. EtmanMK,WoolfordMJ,DunneS.Quantitative measurementoftoothandceramicwear:invivostudy.

InternationalJournalofProsthodontics2008;21:245–52.

2. KarakocaS,YilmazH.Influenceofsurfacetreatmentson surfaceroughness,phasetransformation,andbiaxial flexuralstrengthofY-TZPceramics.JournalofBiomedical MaterialsResearchPartB:AppliedBiomaterials2009;91:930–7.

3. MochalesC,MaertenA,RackA,CloetensP,MuellerWD, ZaslanskyP,etal.Monoclinicphasetransformationsof zirconia-baseddentalprostheses,inducedbyclinically practisedsurfacemanipulations.ActaBiomaterialia2011;7:

2994–3002.

4. MaertenA,ZaslanskyP,MochalesC,TraykovaT,Mueller WD,FratzlP,etal.Characterizingthetransformationnear indentsandcracksinclinicallyuseddentalyttria-stabilized zirconiumoxideconstructs.DentalMaterials2013;29:241–51.

5. AboushelibMN,WangH.Effectofsurfacetreatmenton flexuralstrengthofzirconiabars.JournalofProsthetic Dentistry2010;104:98–104.

6. LuthardtRG,HolzhuterMS,SandkuhlO,HeroldV,Schnapp JD,KuhlischE,etal.ReliabilityandpropertiesofgroundY- TZP-zirconiaceramics.JournalofDentalResearch2002;81:

487–91.

7. VagkopoulouT,KoutayasSO,KoidisP,StrubJR.Zirconiain dentistry:Part1.Discoveringthenatureofanupcoming bioceramic.EuropeanJournalofEstheticDentistry2009;4:

130–51.

8. OhWS,DeLongR,AnusaviceKJ.Factorsaffectingenamel andceramicwear:aliteraturereview.JournalofProsthetic Dentistry2002;87:451–9.

9. PreisV,BehrM,HandelG,Schneider-FeyrerS,HahnelS, RosentrittM.Wearperformanceofdentalceramicsafter grindingandpolishingtreatments.JournaloftheMechanical BehaviorofBiomedicalMaterials2012;10:13–22.

10.PreisV,BehrM,KolbeckC,HahnelS,HandelG,RosentrittM.

Wearperformanceofsubstructureceramicsandveneering porcelains.DentalMaterials2011;27:796–804.

11.CattaniLorenteM,ScherrerSS,RichardJ,DemellayerR, Amez-DrozM,WiskottHWA.SurfaceroughnessandEDS characterizationofaY-TZPdentalceramictreatedwiththe CoJetTMSand.DentalMaterials2010;26:1035–42.

12.HallmannL,UlmerP,ReusserE,Ha¨mmerleCHF.Effectof blastingpressure,abrasiveparticlesizeandgradeonphase transformationandmorphologicalchangeofdental zirconiasurface.SurfaceandCoatingsTechnology2012;206:

4293–302.

13.WangF,ChenJ,WangH.Surfaceroughnessofanovel dentalporcelainfollowingdifferentpolishingprocedures.

InternationalJournalofProsthodontics2009;22:178–80.

14.StawarczykB,OzcanM,SchmutzF,TrottmannA,RoosM, Ha¨mmerleCHF.Two-bodywearofmonolithic,veneered andglazedzirconiaandtheircorrespondingenamel antagonists.ActaOdontologicaScandinavica2013;71:102–12.

15.JanyavulaS,LawsonN,CakirD,BeckP,RampLC, BurgessJO.Thewearofpolishedandglazedzirconia againstenamel.JournalofProstheticDentistry2013;109:

22–9.

16.KrejciI,AlbertP,LutzF.Theinfluenceofantagonist standardizationonwear.JournalofDentalResearch1999;78:

713–9.

17.ShortallAC,HuXQ,MarquisPM.Potentialcountersample materialsforinvitrosimulationweartesting.Dental Materials2002;18:246–54.

18.MairLH,StolarskiTA,VowlesRW,LloydCH.Wear:

mechanisms,manifestationsandmeasurement.Reportofa workshop.JournalofDentistry1996;24:141–8.

19.JohanssonA,KiliaridisS,HaraldsonT,OmarR,CarlssonGE.

Covariationofsomefactorsassociatedwithocclusaltooth wearinaselectedhigh-wearsample.ScandinavianJournalof DentalResearch1993;101:398–406.

20.KimSK,KimKN,ChangIT,HeoSJ.Astudyoftheeffectsof chewingpatternsonocclusalwear.JournalofOralRehabilitation 2001;28:1048–55.

21.MairLH.Wearindentistry–currentterminology.Journalof Dentistry1992;20:140–4.

22.CondonJR,FerracaneJL.Invitrowearofcompositewith variedcure,fillerlevel,andfillertreatment.JournalofDental Research1997;76:1405–11.

23.HickelR,RouletJF,BayneS,HeintzeSD,Mjo¨rIA,PetersM, etal.Recommendationsforconductingcontrolledclinical studiesofdentalrestorativematerials.ClinicalOral Investigations2007;11:5–33.

24.HeintzeSD.Howtoqualifyandvalidatewearsimulation devicesandmethods.DentalMaterials2006;22:712–34.

25.Al-AmlehB,LyonsK,SwainMV.Clinicaltrialsinzirconia:

asystematicreview.JournalofOralRehabilitation2010;37:

641–52.

26.AllahkaramiM,HananJC.Mappingthetetragonalto monoclinicphasetransformationinzirconiacoredental crowns.DentalMaterials2011;27:1279–84.

27.GuazzatoM,AlbakryM,RingerSP,SwainMV.Strength, fracturetoughnessandmicrostructureofaselectionofall- ceramicmaterials.PartII.Zirconia-baseddentalceramics.

DentalMaterials2004;20:449–56.

28.ChintapalliRK,MarroFG,Jimenez-PiqueE,AngladaM.

Phasetransformationandsubsurfacedamagein3Y-TZP aftersandblasting.DentalMaterials2013;29:566–72.

29.OzcanM,MeloRM,SouzaROA,MachadoJPB,FelipeValandro L,BotttinoMA.Effectofair-particleabrasionprotocolsonthe biaxialflexuralstrength,surfacecharacteristicsandphase transformationofzirconiaaftercyclicloading.Journalofthe MechanicalBehaviorofBiomedicalMaterials2013;20:19–28.

30.CullityBD.ElementsofX-raydiffraction.Reading,MA:

Addison-WesleyPub.Co.;1956.

31.KosmacT,OblakC,JevnikarP,FundukN,MarionL.Strength andreliabilityofsurfacetreatedY-TZPdentalceramics.

JournalofBiomedicalMaterialsResearch2000;53:304–13.

32.JuyA,AngladaM.Surfacephasetransformationduring grindingofY-TZP.JournaloftheAmericanCeramicSociety 2007;90:2618–21.

33.AnnamalaiVE,SornakumarT,GokularathnamCV, KrishnamurthyR.Transformationsduringgrindingofceria- stabilizedtetragonalzirconiapolycrystals.Journalofthe AmericanCeramicSociety1992;75:2559–64.

34.DenryIL,HollowayJA.Microstructuralandcrystallographic surfacechangesaftergrindingzirconia-baseddental ceramics.JournalofBiomedicalMaterialsResearchPartB:

AppliedBiomaterials2006;76:440–8.

35.MehtaK,JueJF,VirkarAV.Grinding-inducedtexturein ferroelastictetragonalzirconia.JournaloftheAmerican CeramicSociety1990;73:1777–9.